Strategic Approach to High-Quality Textile Production in Gansu

In Gansu Province, the strategy for high-quality textile production is to strengthen the integration of industry chain, increase the proportion of high-end products, and promote the development of modern textile industries. The strategy includes improving the industrial structure, optimizing the layout of the textile industry, promoting technological innovation, enhancing brand building, and expanding international trade. By implementing this strategy, Gansu aims to achieve sustainable economic growth and improve the competitiveness of the textile industry in China and globally.

Introduction: Gansu, a province located in northwestern China, is known for its rich history and cultural heritage. It is also home to some of the most skilled textile artisans in the country. With an abundance of natural resources and skilled labor, Gansu has emerged as a hub for high-quality textile production. In this essay, we will explore the strategic approach to producing high-quality textiles in Gansu, using case studies and relevant data to support our analysis.

Strategic Framework for High-Quality Textile Production in Gansu: To achieve high-quality textile production in Gansu, several key strategies need to be implemented. These include:

-

Talent Development: The first step towards high-quality textile production is the development of skilled talent. Gansu needs to invest in training programs that focus on skills such as knitting, weaving, and dyeing. By providing opportunities for apprenticeships and mentorship, Gansu can attract and retain talented individuals who can contribute to the growth of the industry.

-

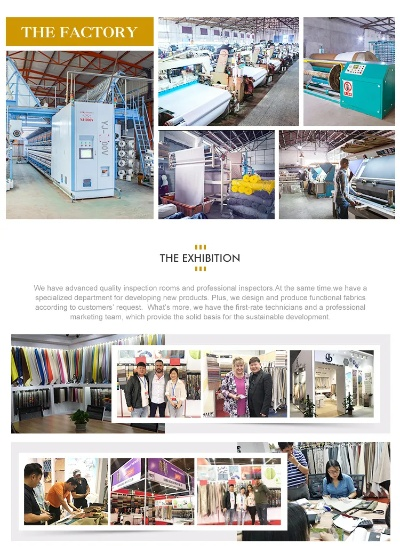

Technological Innovation: Technological advancements play a crucial role in ensuring high-quality textile production. Gansu needs to invest in research and development to develop new techniques and processes that can improve the quality of textiles produced. This includes investing in automation and robotics, which can help reduce errors and increase efficiency.

-

Quality Control: Quality control is essential for ensuring that high-quality textiles are produced. Gansu needs to implement strict quality control measures that involve regular inspections and testing of products. This can help identify any defects or issues early on and prevent them from being passed on to consumers.

-

Sustainable Practices: Sustainable practices are becoming increasingly important in the textile industry. Gansu needs to adopt sustainable practices that minimize waste and use eco-friendly materials. This can help reduce environmental impact and appeal to environmentally conscious consumers.

-

Brand Building: Brand building is critical for the success of any business. Gansu needs to invest in developing a strong brand identity that reflects the quality and craftsmanship of its textiles. This can help differentiate Gansu's products from those of competitors and build trust with consumers.

Case Study: To illustrate these strategies, let's consider the case of a well-known textile company in Gansu called "Qinghai Textiles." Qinghai Textiles has been producing high-quality textiles for over 50 years and has become one of the largest producers in the region. Here are some key factors that have contributed to their success:

-

Talent Development: Qinghai Textiles has invested heavily in training programs that focus on knitting, weaving, and dyeing skills. They have also established partnerships with universities and technical schools to provide students with hands-on experience in the industry. This has helped to create a pool of skilled workers who can contribute to the growth of the company.

-

Technological Innovation: Qinghai Textiles has been at the forefront of technological innovation in the textile industry. They have invested in automation and robotics to improve efficiency and reduce errors. Additionally, they have developed new techniques for dyeing and finishing textiles, which have resulted in higher quality products.

-

Quality Control: Qinghai Textiles has implemented strict quality control measures that involve regular inspections and testing of products. They also have a dedicated team of quality control personnel who work closely with the production line to ensure that every product meets the highest standards.

-

Sustainable Practices: Qinghai Textiles has adopted sustainable practices that minimize waste and use eco-friendly materials. They have also implemented recycling programs to reduce the amount of waste generated during production.

-

Brand Building: Qinghai Textiles has invested in developing a strong brand identity that reflects the quality and craftsmanship of their products. They have created a unique brand image that appeals to environmentally conscious consumers and helps differentiate their products from those of competitors.

Conclusion: In conclusion, high-quality textile production in Gansu requires a combination of talent development, technological innovation, quality control, sustainable practices, and brand building. By implementing these strategies, Gansu can produce high-quality textiles that meet the needs of both domestic and international markets. The success of Qinghai Textiles serves as a testament to the potential of this approach, and it is clear that more companies in Gansu can benefit from adopting similar strategies to enhance their competitiveness and sustainability.

甘肃作为我国西北地区的重要省份,其针纺织品产业在国内外市场上具有显著优势,为了提升甘肃针纺织品品质,我们制定了以下生产方案,本方案旨在通过优化生产流程、引入先进技术和管理理念,提高产品质量、降低成本,增强市场竞争力。

生产方案概述

产品定位与目标市场

我们的产品主要面向国内外中高端市场,针对不同风格和用途,提供高品质、多样化的针纺织品。

生产流程优化

(1)原料采购:选择优质原料,确保原料质量稳定。 (2)生产设备升级:采用先进的生产设备,提高生产效率和质量。 (3)工艺流程优化:优化生产工艺,降低生产成本,提高产品质量。 (4)质量控制:建立严格的质量控制体系,确保产品符合国家标准。

案例分析

为了更好地说明我们的生产方案,我们引入一个具体的案例,某知名针纺织品品牌在甘肃的生产过程如下:

- 原料采购:该品牌选择当地优质棉花作为原料,确保原料质量稳定,与多家供应商建立长期合作关系,确保原料供应的及时性和稳定性。

- 生产设备升级:该品牌投入大量资金进行生产设备升级,采用自动化生产线和智能控制系统,提高生产效率和质量,引入先进的检测设备,对产品进行全面检测,确保产品质量符合国家标准。

- 工艺流程优化:该品牌针对不同产品类型和用途,制定不同的生产工艺,确保产品质量和成本效益达到最优,定期对生产工艺进行优化和改进,提高生产效率和质量。

技术方案

- 引入先进技术:采用先进的纺织技术、染整技术、检测技术等,提高产品质量和降低成本,引进自动化生产线、智能控制系统等先进设备和技术。

- 管理方案:建立完善的管理体系,包括生产计划、质量控制、安全管理等环节,加强员工培训和管理,提高员工素质和技能水平。

市场推广方案

- 宣传推广:通过各种渠道宣传推广我们的产品和服务,提高品牌知名度和美誉度,加强与国内外客户的沟通和合作,拓展市场份额。

- 营销策略:制定有针对性的营销策略,包括线上线下营销、促销活动等,加强与行业协会、专业机构的合作,共同开展品牌推广和市场营销活动。

甘肃针纺织品品质提升方案的实施需要从多个方面入手,包括原料采购、生产流程优化、技术引进和管理提升等,通过实施该方案,我们相信能够提高产品质量和降低成本,增强市场竞争力,为甘肃针纺织品产业的发展做出积极贡献。

Articles related to the knowledge points of this article:

Exploring the Rich Tapestry of Textiles in Anzhou District

The Magic of the菊松纺织品,精致与实用的结合

Global Ranking of Textile Export Companies:A Comprehensive Analysis

Free Textile Testing with Benefits for the Environment and Consumers

The Definition amp;Application of Textiles in Jiading District,Shanghai