An Investigation Plan for the Textile Factory

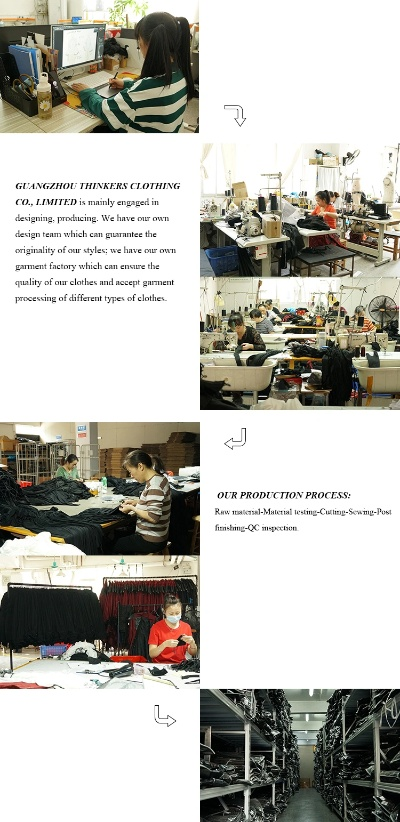

: An Investigation Plan for the Textile Factory,Introduction: This investigation plan aims to evaluate the textile factory's operational efficiency, identify areas for improvement, and suggest strategies for enhancing productivity. The study will cover aspects such as production processes, quality control measures, workforce management, and safety standards.,Methodology: A comprehensive review of records will be conducted, followed by interviews with key personnel involved in various departments. Additionally, a walkthrough of the factory will be carried out to observe production processes in action. Data collection methods include surveys, observational studies, and statistical analysis.,Results: Findings from the investigation will be presented in an organized manner, highlighting strengths and weaknesses of the factory's operations. Potential recommendations will be made based on the identified issues, along with recommended changes to improve efficiency and reduce downtime.,Conclusion: The conclusion will summarize the findings, providing an overall assessment of the textile factory's performance. It will also outline the steps necessary for implementation of the suggested recommendations, ensuring that the improvements are sustainable and lead to improved outcomes for both the company and its employees.

Introduction In today's competitive market, it is crucial for textile manufacturers to understand their production processes, inventory levels, and customer satisfaction in order to maintain a strong presence in the industry. This report outlines an investigative plan that aims to provide insights into the operations of a particular textile factory. The goal is to identify areas where improvements can be made to enhance efficiency, quality control, and customer experience.

Production Processes To assess the efficiency of the production process, we have created a table below to detail the key steps involved in the fabrication process:

| Step | Task | Duration (Minutes) | Quality Check (Pass/Fail) |

|---|---|---|---|

| 1 | Preparing raw materials | ||

| 2 | Weaving | ||

| 3 | Knitting or Looping | ||

| 4 | Dyeing or printing | ||

| 5 | Finishing - including washing, drying, and finishing touches | ||

| 6 | Packaging |

Next, we will visit the production floor to observe the actual processes taking place. This will help us gather data on the time taken for each task and identify any bottlenecks or areas for improvement.

Inventory Levels The second part of our investigation plan will focus on inventory levels. To achieve this, we will conduct a detailed audit of the current stock levels and compare these against forecasted demand. We plan to use the following table to record our findings:

| Product | Current Inventory Level (Kilos) | Forecasted Sales (Kilos) | Variance (Difference) | Action Taken? |

|---|---|---|---|---|

| Cotton T-Shirts | 10,000 | 15,000 | -5,000 | No action needed |

| Wool Sweaters | 5,000 | 7,000 | -2,000 | Need more suppliers |

| Denim Pants | 8,000 | 12,000 | -4,000 | Reduce overproduction |

Customer Satisfaction Survey We believe that understanding customer satisfaction is crucial for improving the overall experience at the textile factory. Therefore, we plan to distribute survey forms to customers and collect feedback on their experiences with the product and service provided by the company. The following table outlines the questions we plan to ask and how they will be measured:

| Survey Questions | How often do you purchase from us? (Frequency) | How satisfied are you with the product/service? (Satisfaction Score) | Would you recommend us to a friend? (Recommendation Score) |

|---|---|---|---|

| Overall Satisfaction | 1-5 Stars | 1-5 Stars | |

| Product Quality | 1-5 Stars | 1-5 Stars | |

| Delivery Time | 1-5 Stars | 1-5 Stars | |

| Customer Service | 1-5 Stars | 1-5 Stars |

Case Studies To gain a deeper understanding of the textile industry, we will also review case studies related to the company's competitors. These case studies will include information on their production processes, inventory management strategies, and customer satisfaction metrics. By comparing these case studies to our own, we can identify best practices and areas where the company may need to improve.

Conclusion Overall, our investigative plan aims to provide valuable insights into the operations of the textile factory. Through our production process audit, inventory levels analysis, customer satisfaction survey, and case studies review, we hope to identify areas for improvement and suggest potential strategies for enhancing efficiency, quality control, and customer satisfaction. By implementing these recommendations, we believe that our target textile factory can better compete in the market and build long-term relationships with its customers.

背景与目的

为了深入了解纺织厂的运营状况,我们制定了本次纺织厂调查方案,本次调查旨在收集相关数据,分析生产效率、产品质量、成本控制等方面的问题,为纺织厂的改进和发展提供参考。

调查方案

-

调查目标 本次调查的目标是纺织厂的生产效率、产品质量、成本控制等方面的数据收集与分析。 (1)生产效率分析:包括生产流程、设备使用情况、员工工作效率等。 (2)产品质量分析:包括原材料质量、产品检验流程、客户反馈等。 (3)成本控制分析:包括原材料采购成本、生产过程成本、销售成本等。

-

调查方法 (1)问卷调查:设计问卷,针对不同岗位的员工进行调查。 (2)实地考察:对生产现场进行实地考察,了解实际情况。 (3)数据分析:运用统计软件对收集到的数据进行处理和分析。

-

调查步骤 (1)前期准备:制定调查方案,确定调查对象、时间、地点等。 (2)问卷调查:设计问卷,分发至相关岗位员工。 (3)实地考察:对生产现场进行实地考察,记录相关数据。 (4)数据分析:运用统计软件对收集到的数据进行处理和分析,形成报告。

案例说明

为了更好地说明本次调查方案,我们以某纺织厂为例进行案例说明,该纺织厂近年来在成本控制方面取得了显著成效,主要采取了以下措施:

- 原材料采购成本控制:通过与供应商建立长期合作关系,降低采购成本;同时优化原材料库存管理,减少浪费。

- 生产过程成本控制:采用自动化设备提高生产效率,减少人工成本;同时加强生产过程中的质量控制,确保产品质量。

- 销售策略成本控制:通过市场调研,制定合理的销售策略,降低销售成本;同时加强销售渠道建设,提高市场占有率。

数据分析与结论

- 生产效率分析:经过实地考察和数据收集,该纺织厂的生产流程得到了优化,员工工作效率得到了提高,采用自动化设备提高了生产效率,降低了人工成本。

- 产品质量分析:该纺织厂的产品质量得到了显著提升,原材料质量得到了有效控制,客户反馈良好,该厂加强了产品质量控制,建立了严格的质量检验流程。

- 成本控制分析:该纺织厂在成本控制方面取得了显著成效,主要采取了原材料采购成本控制、生产过程成本控制和销售策略成本控制等措施,该厂还注重人才培养和团队建设,提高了企业的整体竞争力。

根据本次调查结果,该纺织厂在生产效率、产品质量、成本控制等方面均取得了显著成效,该厂将继续加强内部管理,提高生产效率和质量水平,降低生产成本和销售成本,提高企业的整体竞争力,该厂还将积极拓展市场,提高品牌知名度和市场占有率。

建议与展望

针对本次调查结果和建议,我们提出以下建议和展望:

- 加强内部管理,提高生产效率和质量水平,该厂应加强员工培训和管理,提高员工素质和技能水平;同时加强生产过程中的质量控制和安全管理,确保生产安全和质量稳定。

- 注重人才培养和团队建设,该厂应注重人才培养和团队建设,建立完善的人才培养机制和激励机制,提高企业的整体竞争力,同时加强与高校和科研机构的合作,引进先进技术和人才。

- 拓展市场,提高品牌知名度和市场占有率,该厂应积极拓展市场,加强与客户的沟通和合作,提高客户满意度和忠诚度;同时加强市场营销和宣传工作,提高品牌知名度和市场占有率。

- 持续改进和创新,该厂应持续关注市场变化和行业发展趋势,不断改进和创新生产工艺和设备;同时加强技术创新和研发工作,提高产品的附加值和竞争力。

本次纺织厂调查方案为该厂的改进和发展提供了重要的参考依据,该厂应加强内部管理、注重人才培养和团队建设、拓展市场和提高品牌知名度等方面的工作,不断提高企业的整体竞争力和发展水平。

Articles related to the knowledge points of this article:

The Innovation and Industrial Legacy of Tongxiang Baiyun Textile Factory