纺织品外观质量检验标准与实践

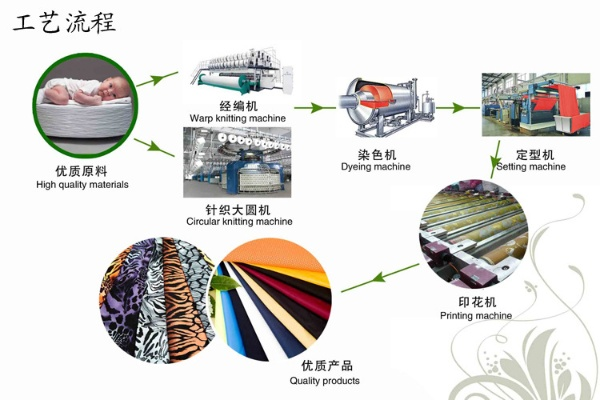

: Standards and Practice of Textile Surface Quality Examination,This paper discusses the standards and practices for examining the surface quality of textile products. The examination focuses on various aspects such as color, texture, and pattern. The standard for color examination is based on the International Organization for Standardization (ISO) 23198-1:2017, which defines the parameters for color measurement and evaluation. The texture examination is conducted using a texture analyzer to measure the roughness and smoothness of the fabric. The pattern examination involves checking the uniformity and accuracy of the printed patterns on the fabric. Additionally, the paper also highlights the importance of proper storage conditions and handling procedures for maintaining the surface quality of textile products. Overall, this paper provides a comprehensive overview of the standards and practices for examining the surface quality of textile products, helping manufacturers to meet their quality requirements and enhance customer satisfaction.

Introduction: In the global textile industry, quality is not just a concern; it's a necessity. Properly inspected and evaluated for appearance, durability, and functionality, textile products are essential for both consumer satisfaction and long-term business success. This guide aims to provide a comprehensive overview of the key aspects of textile product quality inspection, including the application of various inspection tools and procedures, as well as highlighting some practical examples that illustrate how these standards are put into practice.

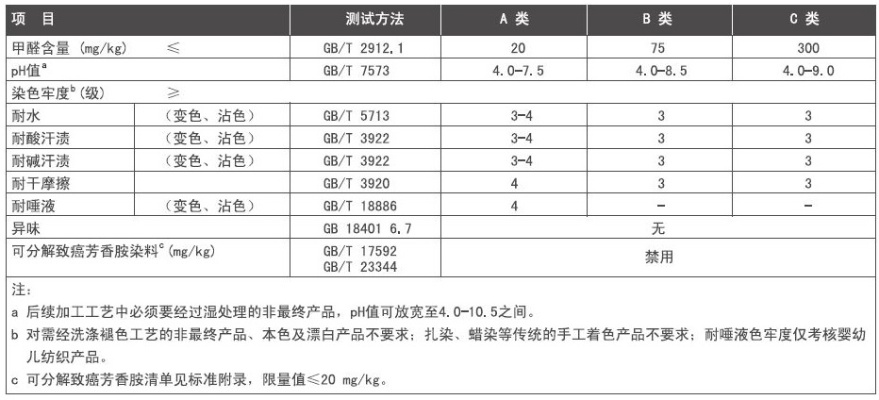

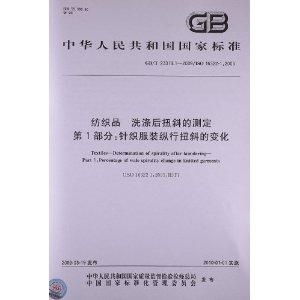

Quality Assurance Standards: The international standards for textile products include the International Organization for Standardization (ISO) standards, ASTM (American Society for Testing and Materials) standards, and other local regulations tailored to specific industries. These standards define the parameters for color accuracy, uniformity, pattern integrity, and other visual attributes. For example, the ISO 2709 standard specifies the requirements for color matching in textiles, while the ISO 14644 standard outlines the methods for measuring fabric thickness and density.

Inspection Tools: To ensure accurate evaluation of textile products’ appearance, several tools and techniques are employed. These include:

- Colorimeter: A device that measures light absorption across a wide range of wavelengths to determine color hue, value, and shade.

- Spectrophotometer: An instrument that uses light to measure the reflectance of an object, providing detailed information about its surface properties.

- Magnifying glass: Used to examine small details or textures on the surface of textile products.

- Tape measure: For measuring dimensions such as width, length, and height.

- Camera: For capturing images of the product to compare with the original design or for documentation purposes.

- Laser scanner: A non-contact method for generating three-dimensional models of textile products.

Practical Examples: One practical example of textile product quality inspection is the process used by a garment manufacturer to check the fit of their shirts. The manufacturer will use a tape measure to measure the chest and sleeve sizes of each shirt before cutting them, ensuring they fit properly according to the design specifications. Additionally, the manufacturer may use a colorimeter to check the color consistency throughout the shirt, ensuring it matches the original design. In this case, the use of colorimeter and tape measure are examples of how inspection tools are applied to evaluate textile appearance.

Conclusion: Quality assurance is crucial for the success of any textile product. By following established international standards and utilizing appropriate inspection tools, manufacturers can ensure that their products meet consumer expectations and remain competitive in the market. It's important to remember that quality control extends beyond just physical inspection; it also involves continuous improvement processes, customer feedback, and innovation to maintain and enhance product quality over time.

纺织品外观质量检验概述

纺织品外观质量检验是确保纺织品产品质量的重要环节,它涉及到对纺织品外观的外观、尺寸、颜色、纹理等各方面的检测,以确保其符合相关标准和客户要求,本文将详细介绍纺织品外观质量检验的方法、流程和注意事项。

方法与流程

材料准备

在进行纺织品外观质量检验前,需要准备好相关的检测设备和材料,包括但不限于尺子、卷尺、显微镜、色差仪等,需要准备好样品,确保样品具有代表性。

外观质量检验

外观质量检验主要包括观察和测量两个方面,观察主要是通过肉眼或放大镜观察样品的外观,包括颜色、纹理、图案等,测量则是通过精确测量样品的尺寸和形状,确保其符合标准要求。

尺寸检测

尺寸检测是纺织品外观质量检验的重要环节,可以采用卷尺、卡尺等工具进行测量,确保样品的尺寸符合标准要求,需要注意测量结果的准确性,避免误差影响检验结果。

颜色检测

颜色检测是纺织品外观质量检验的重要指标之一,可以采用色差仪进行颜色测试,了解样品的颜色分布和偏差情况,需要注意颜色测试的准确性,避免误差影响检验结果。

案例分析

以某品牌纺织品为例,进行纺织品外观质量检验的案例分析,该品牌在纺织品生产过程中,注重外观质量检验,确保产品质量符合客户要求,在外观质量检验过程中,采用了多种检测方法,包括观察、测量、颜色测试等,注重测量结果的准确性,避免误差影响检验结果。

注意事项

-

保持工作环境的整洁和卫生,避免灰尘和杂质影响检测结果。

-

严格按照检测标准和操作规程进行操作,确保检测结果的准确性和可靠性。

-

对于不同材质和颜色的样品,需要采用不同的检测方法和仪器,确保检测结果的全面性和准确性。

英文表格补充说明

以下是纺织品外观质量检验的相关英文表格补充说明:

表格1:纺织品外观质量检验流程图

| 步骤 | 描述 | 设备/材料 |

|---|---|---|

| 材料准备 | 准备检测设备和材料 | 尺子、卷尺、显微镜、色差仪等 |

| 外观质量检验 | 观察样品外观 | 肉眼或放大镜 |

| 尺寸检测 | 使用卷尺或卡尺测量样品尺寸 | 卷尺、卡尺等工具 |

| 颜色检测 | 使用色差仪测试样品颜色分布和偏差情况 | 色差仪 |

| 注意事项 | 工作环境的整洁和卫生 | 无 |

英文案例说明

以某品牌纺织品为例,该品牌在纺织品生产过程中,注重外观质量检验,在外观质量检验过程中,采用了多种检测方法,包括观察、测量和颜色测试等,该品牌注重测量结果的准确性,采用了高精度的测量工具和仪器,确保测量结果的准确性,该品牌还采用了先进的颜色测试技术,能够更准确地了解样品的颜色分布和偏差情况,该品牌生产的纺织品外观质量符合客户要求,得到了客户的好评。

Articles related to the knowledge points of this article:

Chinas Progressive Tariff Rate System for Imported Textile Goods

Underwater Lint Removal:The Process of Textile Processing