The Fabric of Innovation:An Aerial Tour of a Textile Factory

: The Fabric of Innovation: An Aerial Tour of a Textile Factory,Abstract:,This article presents an aerial tour of a textile factory, focusing on the innovative processes and technologies employed in the production process. Through this tour, we explore how the fabric of innovation is woven into the very fabric of the industry, shaping its future direction and driving progress towards sustainable development. The tour highlights the importance of creativity, collaboration, and technological advancements in shaping the future of textile manufacturing.,Introduction:,Textile manufacturing has undergone significant transformations over the years, driven by innovation and technological advancements. This article delves into the fabric of innovation that underpins the industry's continued growth and development. We will take an aerial tour of a textile factory to showcase the various processes and technologies used in the production of high-quality textile products.,Aerial Tour:,As we soar over the textile factory, we see firsthand the intricate process of creating textiles. From the initial design stage to the final product, each step is meticulously crafted to ensure quality and sustainability. We witness the use of advanced machinery and technology to transform raw materials into finished products, highlighting the importance of innovation in driving productivity and efficiency.,Conclusion:,The fabric of innovation is woven into the very fabric of textile manufacturing, shaping its future direction and driving progress towards sustainable development. By exploring the aerial tour of a textile factory, we gain a deeper understanding of the importance of creativity, collaboration, and technological advancements in shaping the future of the industry.

Introduction: In the heart of the textile industry lies a place where creativity meets production. Today, we'll take a bird's-eye view of one such hub - the dynamic and technologically advanced textile factory. From the meticulous craftsmanship to the cutting-edge machinery, this facility is not just a producer of fabric but a pioneer in sustainable practices. Let's dive into the world of threads, colors, and innovation.

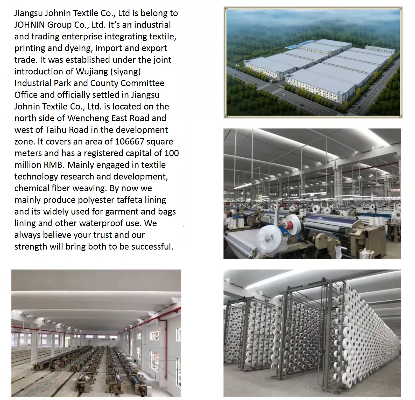

Textile Industry Overview: The textile industry is one of the largest in the world, with billions of dollars invested annually in research, development, and manufacturing. It encompasses everything from clothing and household items to industrial fabrics and technical materials. The textile sector is characterized by its diversity, with countless types of fibers, dyes, and finishing processes.

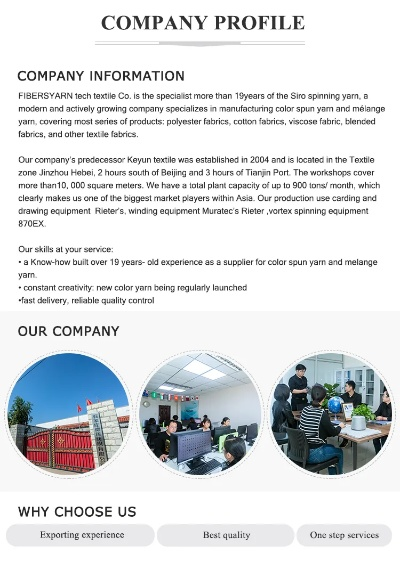

Our focus today is on the textile factory that stands out for its innovative approach to sustainability and efficiency. This factory employs state-of-the-art technology and practices that have transformed the industry. In this article, we will explore its operations, the challenges it faces, and how it balances tradition with modernity.

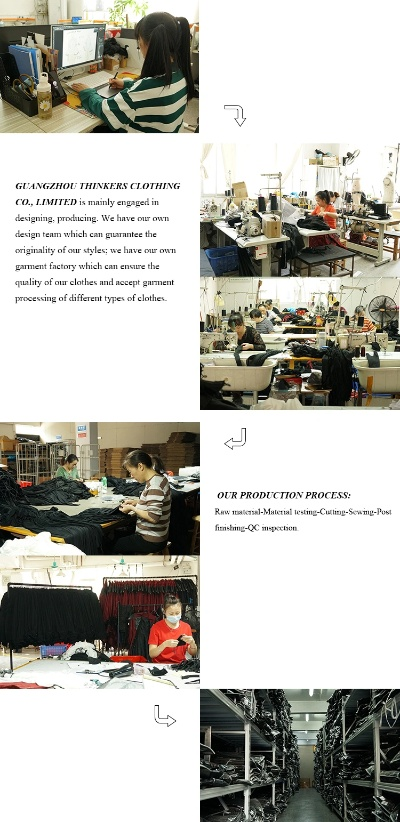

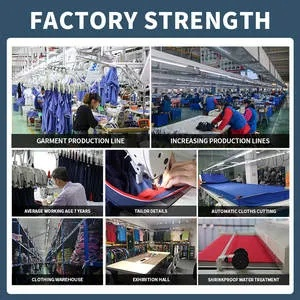

Operational Details: The textile factory operates on a large scale, with an annual output of millions of square meters of fabric. Its production process involves several stages, from raw material procurement to finished product assembly. Here's a breakdown of the key steps:

- Raw Materials: The factory sources its raw materials from various suppliers worldwide, ensuring quality and consistency.

- Preparation: The raw materials undergo thorough preparation before being processed into yarns or threads.

- Weaving/Knitting: These are the two primary methods used in the textile industry. Weaving involves interlacing warp threads, while knitting involves looping them together.

- Dyeing: After weaving or knitting, the fabric is dyed using eco-friendly dyes.

- Finishing: This stage includes treatments like printing, embroidery, and coating to enhance the fabric's appearance and functionality.

- Packaging: Finally, the finished product is packaged for distribution to retailers, wholesalers, or direct to consumers.

Sustainability Practices: At this textile factory, sustainability is not just a buzzword; it's a guiding principle that shapes every aspect of their operations. Here are some examples of their sustainable practices:

| Sustainability Practice | Description |

|---|---|

| Energy Efficiency | The factory uses renewable energy sources like solar panels and wind turbines to power its operations. |

| Waste Management | Recycling waste materials and reducing water usage are integral parts of their waste management system. |

| Eco-Friendly Dyes | They use natural dyes derived from plants and minerals, reducing the environmental impact of traditional chemical dyes. |

| Biodegradable Finishes | Many of their products feature biodegradable finishes that break down naturally, reducing the need for harmful chemicals. |

| Community Involvement | The factory actively engages with local communities, providing job opportunities and supporting community initiatives that promote sustainability. |

Case Study: One example of this factory's commitment to sustainability is their partnership with local farmers who grow the raw materials needed for their fabrics. This collaboration helps reduce transportation emissions and ensures that the fabrics are ethically sourced. Moreover, they support local artisans who produce the yarns and threads used in their products, further fostering a sense of community and sustainability within the industry.

Conclusion: From the intricate weaves of the fabric to the innovative technologies at play, this textile factory embodies the spirit of innovation and sustainability. By adopting sustainable practices, they not only contribute to the environment but also set a benchmark for other industries to follow. As we continue to grapple with issues like climate change and resource depletion, it's essential that businesses like this one lead the way in finding solutions that prioritize both profitability and social responsibility. So, next time you see a beautifully woven piece of clothing or a durable piece of equipment, remember that behind it all lies a team of dedicated individuals who are not only making something beautiful but also making a difference in the world.

随着科技的飞速发展,纺织行业也在不断进步,我们将通过航拍视角,深入了解一家纺织厂的运营情况,探讨其生产流程、技术创新以及未来的发展趋势。

纺织厂位于某城市郊区,占地面积广阔,拥有先进的生产设备和技术,该厂主要生产各类纺织品,包括但不限于棉布、丝绸、毛线等,工厂内部布局合理,生产流程清晰,体现了高度的工业化和自动化水平。

航拍视角下的生产流程

原料采集

在航拍视角下,可以看到原料从农田、森林等地采集而来,经过专业的运输车运送到纺织厂,原料的质量和种类直接影响到纺织产品的品质和性能。

生产线概述

纺织厂拥有先进的生产线,包括织布机、染料处理设备、印花机等,这些设备都是自动化程度较高的生产线,大大提高了生产效率,工厂还注重环保和节能,采用环保材料和节能技术,减少对环境的污染和能源的消耗。

工艺流程展示

在工厂内部,我们可以看到具体的工艺流程,在织布环节,工人使用先进的织布机将原料织成各种形状和大小的布片;在染色环节,工人使用专业的染料处理设备对布片进行染色处理;在印花环节,工人使用印花机将图案印在布片上,整个生产流程体现了高度的工业化和自动化水平。

技术创新与未来发展趋势

技术创新

在纺织行业中,技术创新是推动行业发展的关键,该纺织厂注重技术创新,采用了先进的生产工艺和技术设备,该厂采用了自动化织布机和染料处理设备,大大提高了生产效率和质量,该厂还注重研发新的纺织材料和技术,以满足市场需求。

随着科技的不断发展,纺织行业将会更加注重绿色、环保、智能等方面的技术创新,未来纺织厂将会更加注重环保和节能,采用更加环保的材料和技术,提高生产效率和产品质量,未来纺织厂还将会更加注重智能化生产,采用人工智能、物联网等技术,提高生产效率和产品质量的同时,降低生产成本和人力成本。

未来发展趋势

随着人们对纺织品的需求不断增加,纺织行业将会继续发展壮大,未来纺织厂将会朝着规模化、智能化、绿色化等方面发展,未来纺织厂还将会注重品牌建设和市场营销,提高产品的知名度和竞争力,未来纺织厂还将会注重人才培养和引进,提高员工的素质和技能水平。

案例说明

以某纺织厂为例,该厂采用了先进的生产工艺和技术设备,注重技术创新和绿色环保,该厂采用了自动化织布机和染料处理设备,大大提高了生产效率和质量,该厂还注重环保和节能,采用环保材料和技术,减少了对环境的污染和能源的消耗,该厂还注重品牌建设和市场营销,提高了产品的知名度和竞争力,在未来发展中,该纺织厂将继续注重技术创新和绿色环保等方面的发展,提高生产效率和产品质量的同时,降低生产成本和人力成本。

Articles related to the knowledge points of this article:

The Global Role of Chinas Textile Industry

The Story of Suzhous Loom and Yarn Manufacturing