The Textile Stability Test An Overview and Practical Applications

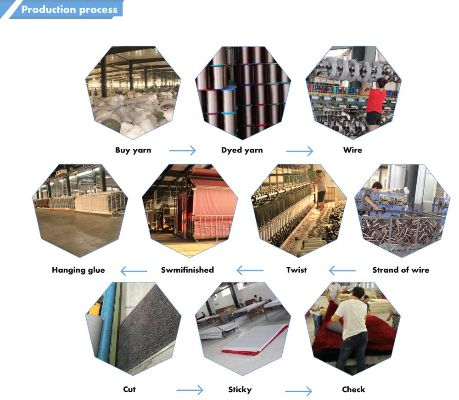

: An Overview and Practical Applications of Textile Stability Test,The textile industry is heavily dependent on the stability of its products in order to maintain quality and consumer satisfaction. The textile stability test aims to evaluate how well a fabric resists changes in its physical properties, such as color, texture, and shrinkage, during various conditions including washing, dry-cleaning, and storage. This paper offers an overview of this crucial test and discusses its practical applications within the textile industry.,Textile stability testing involves subjecting samples to controlled conditions designed to mimic real-world scenarios. Common parameters include temperature variations, pH levels, and exposure to light and chemicals. Results from these tests are critical for manufacturers in ensuring product reliability and longevity.,In practical applications, textile stability testing is used to develop and improve products for specific market segments. For example, clothing companies may conduct these tests on fabrics intended for outdoor wear or swimwear. By understanding the performance characteristics of different fabrics under different conditions, manufacturers can design products that are not only aesthetically pleasing but also durable and functional.,Furthermore, the textile stability test is essential for complying with regulatory standards and certification requirements, such as ASTM D517, ISO 20743, and ECO-FRA (European Cotton Foundation). These standards define minimum performance thresholds for various types of textile materials, and passing these tests ensures that products meet the necessary quality standards.,In conclusion, the textile stability test is vital for maintaining the quality and longevity of textile products. Its practical application in the textile industry is extensive, ranging from product development to compliance with regulatory standards. As such, it remains a critical component in the production process, ensuring that consumers receive products that meet high standards of durability and quality.

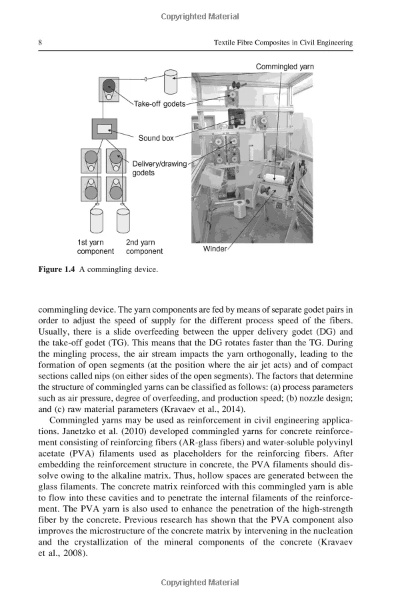

Introduction: The textile industry is a complex and ever-evolving sector that demands high standards of quality control. One of the crucial parameters that determine the longevity and functionality of a textile product is its resilience against deformation. This article will provide an overview of the textile stability test, its practical applications, and how it can be used to ensure products meet the necessary requirements for use in various industries.

Textile Stability Test: The textile stability test involves subjecting fabric samples to controlled forces to measure their resistance to creasing or bending under specific conditions. This method assesses the strength and flexibility of materials and helps manufacturers understand how these properties influence their product's performance over time.

Testing Parameters: The primary parameters for the textile stability test include tensile strength, elongation, modulus, and stiffness. Tensile strength measures how much force is required to stretch a sample; elongation is the extent to which a sample lengthens when subjected to stretching; modulus reflects the material’s ability to resist deformation; and stiffness evaluates the resistance to bending.

Practical Applications:

-

Industrial Applications: The textile stability test is widely used in various industrial sectors, including apparel, footwear, home furnishings, and sportswear. For example, a garment manufacturer may require a sample to demonstrate its durability during washing and wear, while a footwear manufacturer might want to ensure that the sole of a shoe can withstand heavy foot pressure without deforming.

-

Medical Applications: Medical textiles like surgical gowns and masks must exhibit excellent stability to prevent contamination during use. A well-executed textile stability test could help ensure these products are free from tears or rips after prolonged use.

-

Textile Packaging: In the textile packaging industry, the textile stability test is essential in ensuring that fabrics don’t become damaged during shipping or storage. It helps companies identify the most suitable packaging materials for different fabric types and reduce the risk of damage during transport.

-

Recycled Fabrics: As demand for sustainable materials rises, many manufacturers are turning to recycled polyester or other synthetic fibers. A textile stability test can help determine how effectively these materials maintain their structural integrity even after repeated washing and use, thereby ensuring they remain functional and aesthetically appealing.

-

Design Innovation: In the fashion industry, the textile stability test is often used to guide designers in creating garment patterns that can withstand the rigors of daily wear and tear. By understanding the fabric's inherent properties, designers can optimize the design and create garments that not only look good but also stand up to the challenges of everyday life.

Example Case Study: Let's consider the case of a new brand launching a line of high-quality athletic wear. They want to ensure their fabrics are strong enough to withstand rigorous workouts without losing their shape. To achieve this, they conduct an extensive textile stability test on their samples, using a range of tests including tensile strength, elongation, and modulus. The results of these tests are then used to tailor the design features of each garment so that they perform optimally under stress and fatigue. By doing so, they not only satisfy their customers but also contribute to the overall sustainability and performance of the brand.

Conclusion: The textile stability test is a critical component of the textile industry, providing a reliable assessment of the material’s physical properties. Whether applied at the industrial level, in medical applications, in textile packaging, recycling efforts, or in the realm of innovative design, this test plays a vital role in ensuring the enduring qualities of textiles. By understanding the parameters and application areas of the textile stability test, companies can better tailor their products to meet the evolving needs of consumers and stakeholders alike.

大家好,今天我们将讨论纺织品抗折测试的重要性及其方法,抗折测试是评估纺织品在各种使用场景下的性能和耐用性的关键指标,下面我们将详细介绍纺织品抗折测试的方法和案例分析。

纺织品抗折测试方法

测试目的

纺织品抗折测试的主要目的是评估纺织品在受到外力作用时能否保持其形状和结构,抵抗折断的能力。

测试原理

纺织品抗折测试通常采用一定的机械力量,使纺织品在一定范围内弯曲,观察其是否能够恢复原状,常用的测试原理包括万能材料试验机、弯曲试验机等。

测试步骤

(1)准备样品:选择符合要求的纺织品样品,确保样品尺寸、形状和材料符合测试要求。

(2)设置参数:根据测试需求设定机械力量的参数,如弯曲速度、弯曲次数等。

(3)进行测试:将样品放置在测试设备上,按照设定的参数进行测试。

(4)数据分析:记录测试数据,分析样品的抗折性能。

测试设备及参数说明

(1)万能材料试验机:用于测量样品的抗折强度、弹性模量等性能指标,常见的参数包括弯曲速度、弯曲次数等。

(2)弯曲试验机:用于模拟实际使用场景下的抗折测试,如地毯、沙发等纺织品。

案例分析

某品牌纺织品抗折测试案例

某品牌近期推出的一款新型纺织品,为了确保其在使用过程中的性能稳定性和耐用性,进行了抗折测试,以下是该案例的详细分析:

- 样品准备:选择符合要求的样品,确保样品尺寸、形状和材料符合测试要求。

- 测试设备及参数设置:使用万能材料试验机进行测试,设定合适的弯曲速度和弯曲次数,确保样品能够充分受力和恢复原状。

- 结果分析:经过多次测试,该品牌的新型纺织品表现出良好的抗折性能,能够抵抗一定程度的折断,该案例表明,通过合理的抗折测试可以确保纺织品在使用过程中的性能稳定性和耐用性。

英文表格补充说明

以下是关于纺织品抗折测试的英文表格补充说明:

| 项目 | 描述 | 数据示例 |

|---|---|---|

| 测试目的 | 评估纺织品在各种使用场景下的性能和耐用性 | 评估纺织品是否能够抵抗外力作用时的折断 |

| 测试原理 | 采用一定的机械力量,使纺织品在一定范围内弯曲 | 万能材料试验机等 |

| 测试步骤 | 准备样品、设置参数、进行测试 | 根据样品尺寸、形状和材料选择合适的设备,设定合适的参数进行测试 |

| 设备及参数说明 | 万能材料试验机 | 如型号为XYZ万能材料试验机,参数包括弯曲速度、弯曲次数等 |

| 案例分析 | 新品纺织品抗折测试结果 | 如某品牌新型纺织品经过多次测试表现出良好的抗折性能等 |

纺织品抗折测试是评估纺织品性能和耐用性的重要指标,通过合理的抗折测试可以确保纺织品在使用过程中的性能稳定性和耐用性,在实际操作中,应选择合适的测试设备和参数,确保测试结果的准确性和可靠性,还应结合实际使用场景进行测试,以便更好地评估纺织品的性能和耐用性。

Articles related to the knowledge points of this article: