The Art of Fabrication:An Interview with a Textile Printer

: The Art of Fabrication: An Interview with a Textile Printer,In the realm of textile printing, where every thread and color is carefully crafted to create a masterpiece, we sat down with one of the most skilled practitioners. This interview delves into the techniques, inspirations, and challenges faced by the printer as they work tirelessly to bring their vision to life. From the delicate balance of colors to the intricate details of each design, their dedication to detail is evident in every stitch. As they share their journey from beginner to expert, we are reminded of the profound impact that textile printing can have on both artists and viewers alike.

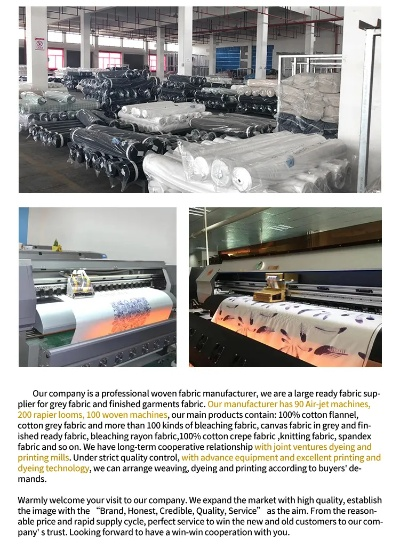

Introduction: In the world of textiles, color and pattern are as essential as the fibers themselves. From the delicate shades of a silk scarf to the bold hues of a denim jacket, the art of printing is the foundation that brings these fabrics to life. Today, we're chatting with a textile printer who has been in this industry for over a decade. Let's dive into their journey, from the initial stages of design to the final product, and see how they bring color to life.

Designing the Pattern: The first step in any print job is designing the pattern. This process involves creating a digital representation of the desired design, which can be done using various software tools like Adobe Illustrator or Sketch. Once the design is finalized, it needs to be translated into a physical format, which is where the textile printer comes in.

Choosing the Right Material: Once the design is ready, the next step is selecting the right material for printing. There are several factors to consider when choosing a fabric, including its weight, texture, and durability. For instance, a lightweight fabric like cotton may be better suited for a summer dress, while a heavyweight fabric like wool might be more appropriate for a winter coat. Additionally, the texture of the fabric can impact how the design looks on it, so it's important to choose one that complements the colors and patterns being printed.

Printing Techniques: There are several printing techniques available, each with its own set of benefits and drawbacks. Here are a few popular ones:

-

Screen Printing: This method involves using a mesh screen to transfer ink onto the fabric. It's ideal for small-scale prints and is relatively inexpensive. However, it can be time-consuming and requires careful handling to avoid leaving any smudging or bleed marks.

-

Pad Printing: This technique uses a pad to apply ink directly onto the fabric. It's faster than screen printing but can be more expensive due to the need for specialized equipment. It's also less versatile than screen printing and may not work well with certain materials.

-

Dye Sublimation: This method involves applying dye to a substrate and then sublimating it through heat. It produces high-quality prints with vivid colors and smooth surfaces. However, it's more expensive than other methods and requires special equipment.

-

Embossing: This technique involves adding raised lines or shapes to the fabric using heat and ink. It creates a three-dimensional effect and adds depth to the design. However, it's not as common as other methods and can be more challenging to achieve precise results.

-

Heat Press: This method involves using a hot iron to transfer designs onto fabric. It's fast and easy to use, but the quality of the prints can vary depending on the quality of the iron and the material being printed.

Quality Control: Once the print job is complete, it needs to go through rigorous quality control measures to ensure it meets the standards required by the customer. This includes checking for proper registration, alignment, and color accuracy. If any issues are found, they need to be addressed promptly to prevent defects from being shipped to the customer.

Case Study: Let's take a closer look at a specific example of a textile printer's journey. Imagine a company called "Textile Innovations," which specializes in custom-designed clothing for both men and women. Their latest project involved designing a line of activewear that was inspired by nature. The team worked closely with a graphic designer to create a unique pattern that incorporated elements of botanical motifs and natural colors.

Using screen printing, the team was able to produce vibrant prints on lightweight cotton fabrics that showcased the beauty of the natural world. The finished products were then sent out to retailers across the country, who were thrilled with the attention to detail and the ability to stand out from their competitors.

Conclusion: From the initial design to the final product, textile printers play a crucial role in bringing color and pattern to life. By understanding the different printing techniques and their respective advantages and disadvantages, businesses can make informed decisions about which approach is best suited for their needs. As technology continues to advance, we can expect even more innovative solutions to emerge in this exciting field.

大家好,今天我们将深入探讨纺织厂染印工的工作日常,作为纺织行业的从业者,他们的工作不仅关乎产品质量,更与人们的日常生活息息相关,下面,我们将通过一个真实的案例和一系列图表,为大家详细介绍纺织厂染印工的工作内容和特点。 概述

染印前的准备工作

在开始染印工作之前,染印工需要做好充分的准备工作,他们需要检查原料的质量,确保染料和印花的颜色和质地符合要求,他们还需要根据订单的规格和要求,制定染印工艺方案。

染印过程

染印过程包括染色和印花两个步骤,染色是将纤维材料浸入染料中,使其着色;印花则是将染料转移到织物表面,形成图案或花纹,在这个过程中,他们需要熟练掌握染料的选择、染色温度和时间等因素,以确保染出的颜色和质量。

工作成果展示

染印工的工作成果包括成品面料、半成品面料等,成品面料通常用于制作衣物、床上用品等,而半成品面料则用于进一步加工或备用,他们的成果展示不仅体现在产品的外观和质量上,还体现在生产效率、成本控制等方面。

案例分析

以一家典型的纺织厂为例,我们可以通过图表来详细分析染印工的工作内容和特点。

【图表一:纺织厂染印工作流程】

- 原料准备:染印工需要检查原料的质量,确保原料符合染印工艺要求。

- 制定工艺方案:根据订单规格和要求,染印工制定染印工艺方案。

- 染色过程:染印工使用特定的染料和染色温度进行染色操作。

- 印花过程:印花工使用印花设备将染料转移到织物表面,形成图案或花纹。

- 工作成果展示:成品面料美观耐用,满足客户要求。

在这个案例中,我们可以看到染印工的工作内容涵盖了原料准备、制定工艺方案、染色操作和印花过程等多个环节,他们需要熟练掌握染料的选择、染色温度和时间等因素,以确保染出的颜色和质量,他们还需要注重生产效率、成本控制等方面,以提高生产效益。 特点

- 高强度工作负荷:纺织厂染印工需要长时间面对高温、高压的工作环境,长时间站立或弯腰工作,需要承受较大的工作负荷。

- 高技术要求:染印工需要熟练掌握染料的选择、染色温度和时间等因素,以及掌握先进的印花设备操作技术,他们需要不断学习和提高自己的技术水平。

- 注重产品质量:纺织厂染印工的工作成果直接关系到产品的质量和客户满意度,他们需要严格把控产品质量,确保产品符合客户要求。

- 注重成本控制:纺织厂染印工需要注重成本控制,提高生产效益,他们需要合理利用资源,降低生产成本,提高生产效率。

- 与其他部门紧密合作:纺织厂染印工需要与生产、质检、销售等部门紧密合作,确保生产过程的顺利进行和产品质量的稳定提高。

纺织厂染印工是纺织行业的重要组成部分,他们的日常工作不仅关乎产品质量和客户满意度,还关系到整个纺织行业的发展和进步,我们希望通过本次介绍,让大家更加了解纺织厂染印工的工作内容和特点,同时也希望大家能够关注和支持纺织行业的发展和进步。

Articles related to the knowledge points of this article:

The Textile Factory Uses a Humidifier to Maintain a Comfortable Work Environment

The Galaxy Weavers of Laiwu:Crafting the Universe of Textiles