Essential Checklist for Customized Textile Production in Guangdong

: An Essential Checklist for Customized Textile Production in Guangdong,Abstract:,This paper aims to provide a comprehensive checklist for customized textile production in Guangdong. The checklist is designed to ensure the quality and consistency of the final product, while minimizing waste and time-consuming processes. It covers various aspects such as raw material selection, cutting and weaving techniques, dyeing and finishing processes, and packaging and shipping procedures. By following this checklist, manufacturers can improve their efficiency and reduce costs while maintaining the high standards required for custom textile products.,Keywords: Customized textile production; Guangdong; Quality control; Waste reduction; Time-saving processes.

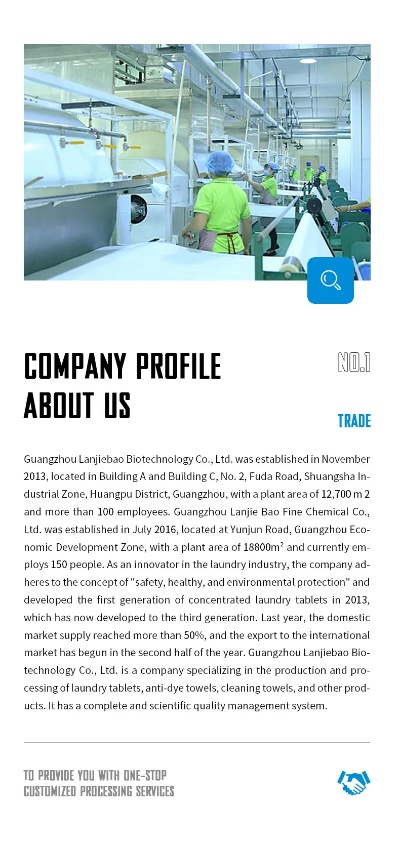

Introduction: Customization is a hallmark of the textile industry, and the Pearl River Delta region of China, particularly Guangdong, has become synonymous with high-quality, bespoke textile products. In this guide, we'll outline the key steps to creating a comprehensive production checklist for your custom textile needs. Our focus will be on tailoring this checklist to meet the specific requirements of your project, ensuring that every detail is taken into account to deliver exceptional results.

Production Checklist:

-

Design Phase

- Conceptualization: Collaborate with designers to create a conceptual drawing or CAD model.

- Sketches: Develop detailed sketches based on the design concepts.

- Prototypes: Create prototypes to test design feasibility and fit.

- Feedback: Get feedback from customers or stakeholders and make necessary adjustments.

-

Material Selection

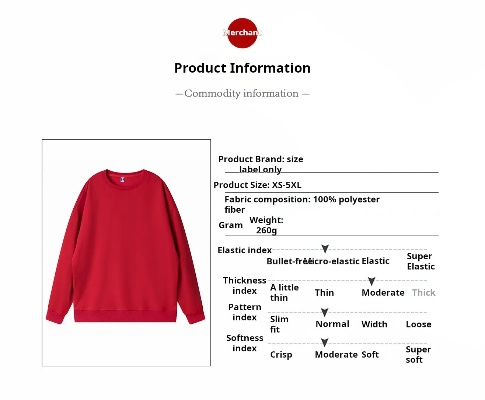

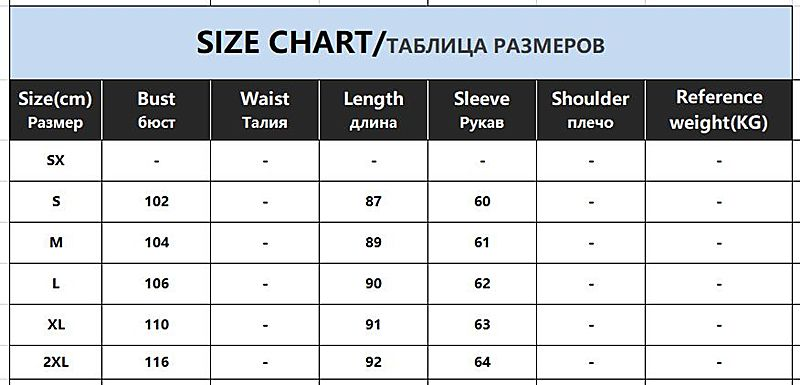

- Fabric Selection: Choose the right fabric based on the design, functionality, and durability required.

- Thread Selection: Select appropriate thread colors, weights, and finishes.

- Pattern Making: Develop patterns for printing, embroidery, or other finishing processes.

-

Manufacturing Process

- Cutting: Cut the fabric according to the pattern.

- Sewing: Stitch the pieces together, including seams, hems, and any other necessary details.

- Dyeing/Printing: Apply dyes or prints to the fabric.

- Embroidery: Add embellishments such as embroidery, appliques, or lacework.

- Finishing: Apply additional treatments like coatings, waxes, or ironing.

-

Quality Control

- Inspection: Conduct quality checks throughout the manufacturing process.

- Sample Testing: Perform sample tests to ensure materials meet specifications.

- Packaging: Ensure packaging meets shipping standards and protects the product during transit.

-

Packaging & Shipping

- Packaging Design: Plan how to package the finished product to ensure it arrives safely.

- Shipping Routes: Determine the most efficient and cost-effective shipping routes.

- Insurance: Include insurance coverage to protect against potential losses during transit.

Case Study: Let's consider a client who needed customized denim jeans. The initial design included a unique wash pattern, which required a special blend of cotton and polyester. The client specified a vintage look with a distressed finish. To achieve this look, we developed a detailed production plan that involved selecting high-quality denim fabrics, using a specialized printing process for the wash pattern, and applying a rustic wax finish for the distressed effect. We also incorporated a hidden pocket detail to enhance the overall style.

Throughout the production process, we closely monitored each step to ensure that the final product met the client's exact specifications. After completing the jeans, we conducted a thorough quality control check, including a sample test of the wash pattern and the overall fit. Finally, we carefully packaged and shipped the jeans to the client in perfect condition, receiving positive feedback on their appearance and quality.

Conclusion: Creating a comprehensive production checklist is crucial in ensuring that your custom textile project is completed to perfection. By following our guide and incorporating the key steps outlined above, you can rest assured that your bespoke textile will meet or exceed your expectations. Remember, the key is to stay flexible and open to feedback along the way, as this will help you adapt to any challenges that may arise during the production process. With careful planning and attention to detail, your custom textile project can become a true masterpiece.

本篇报告旨在详细介绍广东地区定制针纺织品生产的相关信息,包括所需材料、工艺流程、设备需求以及案例分析,通过这份清单,我们希望为相关行业从业者提供参考,以便更好地了解广东地区针纺织品定制生产的情况。

材料准备

- 纱线:主要选用高品质棉纱,确保织物柔软舒适。

- 织布材料:包括棉布、涤纶布、丝绸等。

- 辅助材料:如染料、印花材料、绣花线等。

工艺流程

- 原料准备:根据客户需求,准备相应的纱线。

- 织布设计:根据客户要求,设计针纺织品图案。

- 织布生产:采用先进的织布工艺,如平纹、斜纹等。

- 染色处理:根据织物材质和颜色需求,进行染色处理。

- 印花绣花:根据图案设计,进行印花和绣花处理。

- 质量检测:确保成品符合相关标准,进行质量检测。

设备需求

- 织布机:用于织布生产的主要设备,包括平纹、斜纹等多种机型。

- 染缸:用于染色处理,确保染料均匀分布。

- 印花机:用于印花绣花处理,提高生产效率。

- 缝纫机:用于缝制辅助材料和成品。

- 其他辅助设备:如熨烫机、烘干机等。

案例分析

- 某针纺织品公司生产定制窗帘案例 该公司主要生产各种材质的窗帘,采用广东地区的优质纱线和织布材料,结合先进的织布工艺和印花绣花技术,成功打造出各种风格和功能的窗帘产品,该公司还配备了先进的缝纫机和熨烫机等设备,确保产品质量和交货速度。

- 某丝绸制品公司定制丝绸围巾案例 该丝绸制品公司主要生产丝绸围巾等丝绸制品,采用高品质的丝绸材料和先进的织造工艺,结合客户个性化需求进行定制,该公司还配备了专业的印花绣花设备和检测设备,确保产品质量和交货速度,该公司还注重环保和可持续发展,采用环保材料和生产工艺,为消费者提供绿色、健康的纺织品。

广东地区针纺织品定制生产具有丰富的资源和经验,同时也有着广阔的市场前景和发展空间,在生产过程中,需要注重材料选择、工艺流程、设备选择等方面的工作,以确保产品质量和交货速度,还需要注重环保和可持续发展,为消费者提供绿色、健康的纺织品,通过本次报告的介绍,相信相关行业从业者能够更好地了解广东地区针纺织品定制生产的情况,为行业的发展做出更大的贡献。

Articles related to the knowledge points of this article:

Exploring the Art of Home with JiaMeiYiJu Textiles