Understanding and Complying with Textile UV Standards

This article discusses the importance of understanding and complying with textile UV standards. It highlights the need for manufacturers to use appropriate materials and processes to ensure that their products do not emit harmful ultraviolet (UV) radiation. The article also explores the impact of UV radiation on human health and the potential risks associated with prolonged exposure to it. By understanding and complying with textile UV standards, manufacturers can reduce the risk of skin damage and other health issues caused by UV radiation. Additionally, this article provides guidance on how to implement effective strategies for monitoring, testing, and maintaining compliance with UV standards. Overall, it is essential for all stakeholders involved in the textile industry to be aware of the importance of UV standards and take proactive steps to ensure their compliance.

Introduction The sun's rays, though necessary for life, can also pose a significant risk to the environment and health. Among the harmful UV radiation, UVB is particularly damaging to skin and eyes, causing sunburn, premature aging, and even skin cancer. Textile materials, such as cotton, polyester, and rayon, absorb and reflect UVB rays differently, affecting their performance in protecting against UV damage and maintaining color. Therefore, ensuring textiles meet appropriate UV standards is crucial not only for protecting human health but also for environmental sustainability. This guide will explore the different types of UV protection, the recommended levels by international standards, and practical examples of how these standards are implemented across various industries.

Types of UV Rays and Their Effects on Textiles UV rays can be broadly categorized into three main types: UVA (320-400 nm), UVB (280-320 nm), and UVC (100-280 nm). Each type has different effects on different parts of the human body. For example, UVA causes long-term damage to collagen fibers in the skin, leading to wrinkles and skin cancer. UVB damages DNA in the skin cells, causing redness, swelling, and burning. UVC is highly toxic and is primarily responsible for disinfection. Textiles that are designed to protect against all three UV types should ideally have UV protection ratings.

Textile UV Protection Ratings International standards for textile UV protection include the UPF (Ultraviolet Protection Factor) rating system developed by the International Organization for Standardization (ISO), and ASTM F96 standard for indoor fabrics. These standards define the percentage of light transmission that a material can block based on its UPF rating.

-

ISO 11012:2017 provides guidelines for determining the UPF value of fabrics and textiles based on their absorption, scattering, and reflection capabilities. The higher the UPF rating, the greater the level of protection against UVB rays. For instance, a UPF 50+ fabric can block up to 98% of UVB, providing significant protection for the skin.

-

ASTM F96:2010 describes the methodologies used to evaluate textiles for indoor use, including their ability to block UVA and UVC radiation, as well as their resistance to fading and staining under artificial lighting conditions.

Compliance with Textile UV Standards To ensure that textile products are compliant with relevant UV standards, it is essential to follow the manufacturing process closely, from raw material selection to end product testing. Here are some key steps manufacturers can take:

-

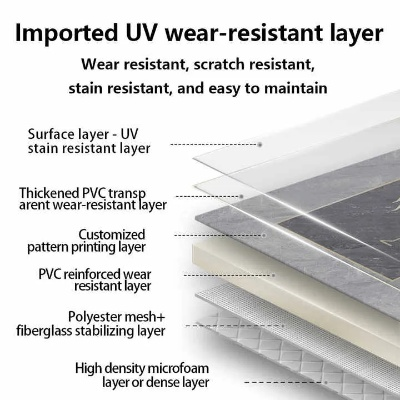

Selection of Materials: Choose materials that absorb or reflect UV radiation effectively. For instance, polyester and nylon are popular choices due to their high UPF values. However, natural fibers like linen may also offer good UV protection.

-

Pretreatments: Some textiles may require pretreatments such as coatings or dyes that enhance their UV resistance. For instance, UV stabilizers can prevent photochemical changes during fabric processing that can reduce UPF values over time.

-

Quality Control: Regular inspections and testing are necessary to ensure compliance with standards. This includes checking for proper colorfastness under UV exposure and measuring the UPF value accurately.

-

Packaging and Labeling: Proper packaging and labeling can also play a role in ensuring consumer trust. It is essential to clearly communicate information about the textile's UV protection properties.

Real-World Examples of Textile UV Standards Implementation Several companies worldwide have adopted and implemented textile UV standards into their manufacturing processes. For example:

-

L'Oreal Paris: The French beauty brand uses eco-friendly materials and innovative technology to create cosmetics that provide excellent UV protection. They also invest in research and development to continually improve their products.

-

Nike: The sportswear giant incorporates UV protection into their athletic apparel. Nike's Air Max and Zoom Vaporfly models are designed to offer maximum protection against UV radiation while still keeping athletes comfortable and looking good.

-

H&M: The Swedish retailer offers an array of clothing items made from sustainable materials that meet strict UPF standards. They also emphasize their commitment to reducing their ecological impact through eco-friendly practices.

Conclusion Textile UV standards are crucial for safeguarding people's health and protecting the environment. By understanding the different types of UV rays and their effects, selecting appropriate materials, following quality control procedures, and implementing real-world examples of industry standards, textile manufacturers can produce products that meet or exceed the necessary protection requirements. As the demand for high-quality, protective textiles continues to grow, staying informed about new advancements in the field will help businesses stay ahead in this competitive market.

随着现代生活水平的提高,人们对纺织品的质量和安全性要求也越来越高,为了确保纺织品在紫外线辐射下的性能和质量,制定并实施纺织品紫外线标准显得尤为重要,本篇文章将围绕纺织品紫外线标准展开讨论,并提供相关的英文案例说明。

纺织品紫外线标准概述

纺织品紫外线标准是指对纺织品在特定波长范围内的紫外线辐射吸收能力和防护性能进行规定和检测的一系列标准,这些标准通常包括但不限于以下内容:

- 紫外线辐射吸收能力测试方法

- 纺织品紫外线防护性能要求

- 相关检测标准和流程

英文案例说明

以下是一个英文案例,用以说明纺织品紫外线标准的实际应用:

案例:某品牌纺织品经过严格测试,符合国际纺织品紫外线标准要求,该品牌采用特殊工艺和技术,确保其纺织品在特定波长范围内的紫外线辐射吸收能力达到国家标准,该品牌还提供多种颜色和款式选择,以满足不同消费者的需求。

纺织品紫外线标准的具体内容

紫外线辐射吸收能力测试方法

(1)测试原理:采用紫外可见分光光度计等设备,对纺织品在特定波长范围内的吸收能力进行测量。 (2)测试仪器:紫外可见分光光度计、样品台、标准光源等。 (3)测试步骤:样品准备、设置测试条件、进行测试、数据记录和分析。

纺织品紫外线防护性能要求

(1)紫外线辐射等级:根据不同用途和需求,设定不同的紫外线辐射等级,如A级、B级等。 (2)防护性能指标:包括紫外线透过率、紫外线吸收率、色牢度等。

相关检测标准和流程

为了确保纺织品紫外线标准的实施和检测,通常需要遵循以下相关检测标准和流程:

- 检测机构选择:选择具有相关资质和经验的检测机构进行检测。

- 样品准备:按照标准要求准备样品,确保样品具有代表性。

- 测试流程:进行紫外线辐射吸收能力测试,同时进行色牢度等其他相关性能测试。

- 结果处理:对测试结果进行记录和分析,确保符合国家标准要求。

- 报告出具:出具检测报告,包括测试结果、防护性能指标等。

纺织品紫外线标准是保障纺织品质量和安全性的重要标准之一,通过制定并实施纺织品紫外线标准,可以确保纺织品在特定波长范围内的紫外线辐射吸收能力和防护性能达到国家标准,从而保障消费者的健康和安全,纺织品紫外线标准的实施和检测也需要遵循相关标准和流程,以确保检测结果的准确性和可靠性。

Articles related to the knowledge points of this article:

The Essential Winter Wardrobe for Your Outdoor Adventures

The National Consumption of Clothing and Textiles:An Analysis