The Fabrication of Aluminum Brushes in the Textile Industry

The process of fabricating aluminum brushes in the textile industry involves a complex series of steps. The initial step is the preparation of aluminum foil, which is then rolled into thin sheets. These sheets are then cut to the desired size and shape, which will determine the final size and shape of the brush. The next step is the application of adhesive to the back of the aluminum sheet, which is then pressed onto a wooden handle. Finally, the brush is dried and cured to ensure that it is stable and durable. The result is an aluminum brush that is both lightweight and highly effective, making it an ideal tool for cleaning and polishing textiles.

Introduction: The textile industry is a vital sector that plays a crucial role in the global economy. It generates significant employment opportunities and contributes to the production of various products, including clothing, footwear, and home furnishings. One of the essential tools used in this industry is aluminum brushes, which are used for cleaning, finishing, and shaping fabrics. In this article, we will explore the manufacturing process of aluminum brushes in the textile industry and provide an overview of their applications.

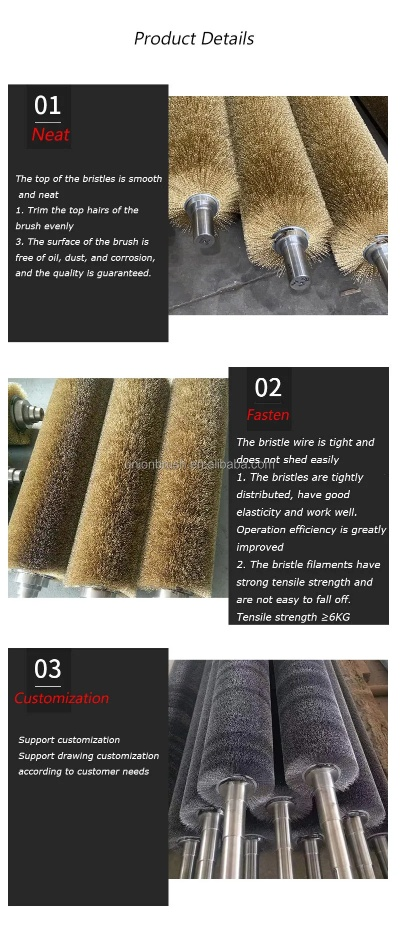

Manufacturing Process of Aluminum Brushes: Aluminum brushes are manufactured using high-quality aluminum alloys, which have excellent corrosion resistance, wear resistance, and durability. The manufacturing process involves several steps, including:

-

Preparation of Aluminum Alloy: The raw material for making aluminum brushes is aluminum alloys, which are processed into different shapes and sizes according to the desired specifications.

-

Forming: The aluminum alloy is then formed into the desired shape by using molds and die-cutting techniques. This step is crucial as it determines the overall size and shape of the brush.

-

Machining: After forming, the aluminum alloy is machined to remove any imperfections or impurities, ensuring that the final product meets quality standards.

-

Polishing: The aluminum alloy is further polished to improve its surface finish and reduce scratches.

-

Finishing: Finally, the aluminum alloy is subjected to a series of finishing processes, such as painting, coating, and polishing, to enhance its appearance and performance.

Applications of Aluminum Brushes in the Textile Industry: Aluminum brushes have a wide range of applications in the textile industry, including:

-

Cleaning: Aluminum brushes are commonly used for cleaning fabrics, especially for delicate materials like silk and wool. They are effective in removing dirt and stains without causing damage to the fabric.

-

Finishing: Aluminum brushes are also used for finishing fabrics, such as ironing and pressing. They help to smooth out wrinkles and creases and create a professional look.

-

Shaping: Aluminum brushes are used for shaping fabrics, such as knitting and weaving. They help to evenly distribute the fibers and prevent them from becoming tangled.

-

Sewing: Aluminum brushes are used in sewing machines to push the needle through fabrics. They help to ensure accurate stitches and prevent puckering.

-

Laundry: Aluminum brushes are also used in laundry machines to clean clothes. They help to remove dirt and stains without damaging the fabric.

Case Study: One example of how aluminum brushes are used in the textile industry is the case of a leading fashion brand that specializes in luxury handbags. The brand uses a specialized aluminum brush called the "Luxe Brush" to apply a high-gloss finish on the leather surfaces of their bags. The Luxe Brush has a unique design that allows for precise control over the application of the finish, resulting in a glossy and vibrant finish that enhances the beauty of the leather. The use of this brush not only improves the aesthetic appeal of the bags but also ensures that the finish is durable and resistant to wear and tear.

Conclusion: In conclusion, aluminum brushes play a crucial role in the textile industry by providing efficient cleaning, finishing, and shaping solutions. Their wide range of applications makes them an essential tool for manufacturers and retailers alike. By understanding the manufacturing process and the various applications of aluminum brushes, we can appreciate their importance in maintaining the quality and integrity of textile products.

纺织厂铝刷简介

纺织厂铝刷是现代纺织生产中不可或缺的工具,它们在提高产品质量、提升生产效率方面发挥着重要作用,铝刷以其独特的材质和特性,为纺织生产带来了许多优势。

铝刷的主要特点

- 高硬度:铝刷采用高强度合金材料制成,具有极高的硬度和耐磨性,能够长时间保持清洁和光滑。

- 环保友好:铝刷在使用过程中不会产生有害物质,符合环保要求,对环境友好。

- 易清洗:铝刷表面光滑,易于清洗,大大降低了人工清洗的难度和成本。

案例分析

以某纺织厂为例,展示铝刷在实际生产中的应用,该纺织厂采用先进的铝刷生产线,大大提高了生产效率和产品质量。

- 生产流程概述:该纺织厂采用自动化生产线,铝刷在生产过程中的主要作用是清除纤维表面的杂质和污垢,确保产品质量。

- 案例分析:该纺织厂使用的铝刷品牌和质量均达到行业领先水平,它们能够有效地清除纤维表面的各种杂质和污垢,提高产品质量和效率,铝刷的清洗和维护也非常方便,大大降低了人工清洗的难度和成本。

铝刷的应用场景

铝刷广泛应用于纺织生产的各个环节,包括织造、染整、印花等多个工序,在织造过程中,铝刷可以清除纤维表面的杂质和纱线之间的残留物,提高织物的质量和产量,在染整过程中,铝刷可以清除纤维表面的色素和染料残留物,提高染料的均匀性和牢度,在印花过程中,铝刷可以清除印花图案表面的杂质和污垢,提高印花图案的清晰度和美观度。

使用铝刷的注意事项

在使用铝刷时,需要注意以下几点:

- 选择合适的铝刷品牌和质量,确保其符合生产要求和使用标准。

- 定期对铝刷进行清洗和维护,保持其清洁度和光滑度。

- 在使用过程中,要避免过度使用和滥用,以免对设备和人员造成损害。

- 在使用过程中要注意安全,避免铝刷对人员和设备造成伤害。

纺织厂铝刷在现代纺织生产中发挥着重要作用,它们可以提高产品质量、提升生产效率,降低生产成本和人工成本,使用铝刷需要注意选择合适的品牌和质量、定期清洗和维护、注意安全等方面的问题,通过不断的技术创新和改进,未来纺织厂铝刷将会更加智能化、高效化,为纺织行业的发展做出更大的贡献。

Articles related to the knowledge points of this article:

The Story of Dongguan Jiangnan Textile Factory

The Galaxy Weavers of Laiwu:Crafting the Universe of Textiles