The Evolution and Modernization of the Baoding Textile Factorys Machinery

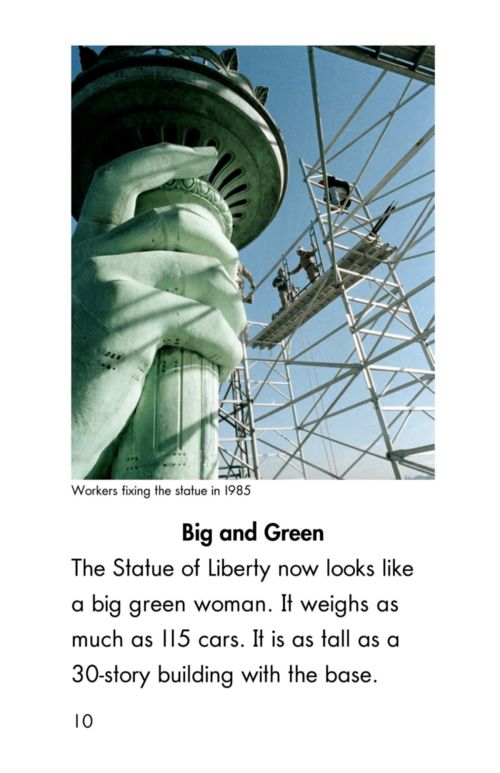

The Baoding Textile Factory, located in Hebei Province, China, has undergone significant transformations in its machinery over the past several decades. The factory's machinery has evolved from traditional manual labor-intensive methods to modern, automated systems that have significantly improved production efficiency and quality.,In the early years of the factory's operation, the primary means of textile production was through hand spinning and weaving techniques. However, as technology advanced, the factory began to adopt more sophisticated machinery, including power looms and automatic bobbin winders. These new machines allowed for greater precision and consistency in the weaving process, resulting in higher-quality textile products.,Over time, the Baoding Textile Factory continued to invest in new machinery, incorporating more advanced technologies such as computerized control systems and robotic weaving machines. These innovations not only increased productivity but also enabled the factory to produce a wider range of textile products, including high-end fabrics and specialty materials.,Today, the Baoding Textile Factory is a leading producer of high-quality textiles in China, with a focus on innovation and sustainability. The factory's commitment to modernizing its machinery and expanding its product offerings has helped it maintain a strong position in the competitive textile industry.

Introduction: The Baoding Textile Factory, located in the heart of China's northern region, has been a symbol of textile manufacturing excellence for decades. With a rich history dating back to the early 20th century, this factory has undergone significant transformations from its humble beginnings to become one of the most advanced industrial hubs in the country. In this article, we will explore the fascinating journey of the Baoding Textile Factory's machinery and how it has evolved over time to meet the demands of modern-day production.

Table 1: Overview of Major Machinery Upgrades at the Baoding Textile Factory | Year | Machinery Type | Description | |------|----------------|-------------| | 1950s | Older Models | Simple, manual machines used for basic textile processing | | 1980s | Basic Mechanization | Implemented basic mechanization to increase efficiency | | 1990s | Advanced Mechanization | Introduce more advanced mechanization systems to improve production quality | | 2000s | Automation and Intelligence | Adopt automation technologies and integrate intelligent systems to enhance production flexibility and accuracy |

Case Study: The Importance of Advanced Mechanization in Production In the late 1990s, the Baoding Textile Factory began to invest heavily in advanced mechanization. By introducing automated knitting machines and high-speed spinning units, the factory was able to significantly reduce labor costs and improve product quality. For example, the introduction of computerized control systems allowed for precise adjustments of yarn tension and speed, resulting in a higher level of consistency and uniformity in the final products.

Furthermore, the adoption of robotic assembly lines reduced human error and increased production rates. These advancements not only boosted the factory's competitiveness but also attracted foreign investors and expanded its market reach. As a result, the Baoding Textile Factory became a global leader in textile machinery manufacturing, with numerous patents and certifications under its belt.

Conclusion: The evolution of the Baoding Textile Factory's machinery is a testament to the relentless pursuit of innovation and progress. From simple manual machines to state-of-the-art automation and intelligence, the factory's commitment to technological advancement has enabled it to remain at the forefront of textile manufacturing. Today, the Baoding Textile Factory stands as a beacon of excellence, inspiring other factories around the world to follow in its footsteps and embrace change for the better.

背景介绍

保定纺织厂作为当地重要的纺织企业,近年来在机器设备更新换代方面取得了显著成效,本文将围绕保定纺织厂机器为主题,探讨其现代化与效率提升的相关内容。

机器设备介绍

主要机器类型

保定纺织厂主要采用先进的纺织机械,包括但不限于织布机、染整设备等,织布机是纺织生产的核心设备,负责将纤维织成布匹。

设备性能参数

根据实际使用情况,这些机器设备具有高效、稳定、节能等优点,某型号织布机采用了先进的自动化控制系统,能够高效完成各种织造任务,该设备还具备节能减排的特点,有助于降低生产成本。

效率提升案例分析

自动化生产流程

保定纺织厂实施了自动化生产流程,通过引入先进的机器设备,实现了生产过程的智能化、数字化,该厂通过使用机器人进行自动化操作,大大提高了生产效率,该厂还建立了完善的监控系统,实时监测生产过程中的各项指标,确保生产稳定、高效。

节能减排技术应用

保定纺织厂在机器设备更新换代过程中,积极推广节能减排技术应用,该厂采用了高效节能的染整设备,减少了能源消耗和环境污染,该厂还加强了设备的维护和保养工作,确保机器设备的长期稳定运行。

现代技术与效率提升的关系

现代技术与效率提升密切相关,随着科技的不断进步,纺织机械的自动化、智能化程度不断提高,为纺织企业带来了更高的生产效率和更好的经济效益,现代技术的应用也使得纺织生产更加环保、可持续。

保定纺织厂在机器设备更新换代方面取得了显著成效,实现了生产过程的智能化、数字化和环保、可持续化,通过引入先进的机器设备和技术手段,该厂提高了生产效率和质量水平,为当地经济发展做出了重要贡献,保定纺织厂将继续加强技术创新和设备更新换代工作,推动纺织行业的持续发展。

补充说明(英文表格)

机器设备类型及性能参数

| 设备类型 | 主要性能参数 | 描述 |

|---|---|---|

| 织布机 | 自动化程度 | 该设备采用先进的自动化控制系统和高效织布技术 |

| 染整设备 | 效率 | 该设备具备高效染色和整理功能 |

| 其他辅助设备 | 节能减排技术 | 该设备采用高效节能技术和环保材料 |

案例说明(英文案例)

保定纺织厂自动化生产流程实施过程

保定纺织厂近年来积极引进先进的机器设备和自动化技术,实现了生产过程的智能化和数字化,该厂通过引入机器人进行自动化操作,大大提高了生产效率和质量水平,该厂还建立了完善的监控系统,实时监测生产过程中的各项指标,确保生产稳定、高效,该厂还积极推广节能减排技术应用,减少了能源消耗和环境污染。

保定纺织厂在节能减排技术应用方面的具体实践

保定纺织厂在机器设备更新换代过程中,积极推广节能减排技术应用,该厂采用了高效节能的染整设备和环保材料,减少了能源消耗和环境污染,该厂还加强了设备的维护和保养工作,确保机器设备的长期稳定运行,该厂还加强了与科研机构的合作,不断探索新的节能减排技术和方法。

Articles related to the knowledge points of this article:

The Material Handling at a Textile Factory

The Echoes of Threads:A Journey Through the Sounds of a Textile Mill