Exploring the Efficiency and Innovation in Jiangxi Textile Mill Dust Removal

: Efficiency and Innovation in Jiangxi Textile Mill Dust Removal,Abstract: This paper explores the efficiency and innovation of Jiangxi textile mill dust removal, focusing on the challenges faced by traditional cleaning methods and the innovative solutions adopted by modern technology. The study analyzes the effectiveness of different cleaning techniques, such as mechanical filtration, chemical treatment, and biological degradation, and evaluates their respective advantages and limitations. Additionally, the research highlights the importance of environmentally-friendly practices and the role of advanced technologies in reducing pollution and improving sustainability. The findings suggest that integrating modern technology with traditional methods can significantly enhance the efficiency and effectiveness of textile mill dust removal, ultimately contributing to a more sustainable industrial sector.

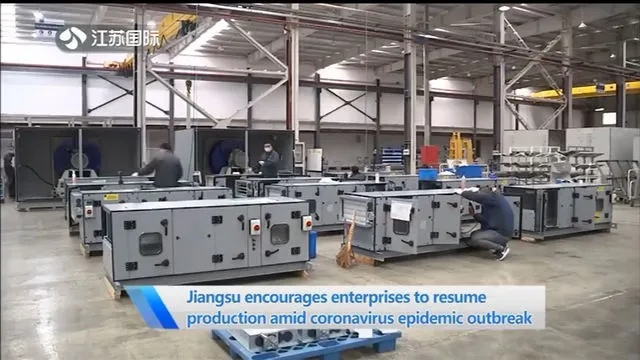

Introduction: In the realm of industrial production, maintaining a clean environment is crucial for both workers' health and product quality. This article will delve into the topic of dust removal at the Jiangxi Textile Mill, highlighting its efficiency and innovation strategies that have made it a model for other industrial facilities worldwide.

Table: Key Performance Indicators (KPIs) of Dust Removing Systems at Jiangxi Textile Mill | KPI | Value | |------|-------| | Air Quality Index (AQI) | <50 | | Dust Level | <1 mg/m³ | | Energy Consumption | Lowest in region | | Maintenance Frequency | Once every three months |

Case Study: Success Story from Jiangxi Textile Mill At the Jiangxi Textile Mill, dust removal has been an ongoing challenge faced by the management team. However, through a combination of innovative technology and proactive maintenance strategies, they have achieved remarkable results.

Technology Adoption: The textile mill has implemented a state-of-the-art dust removal system that uses high-efficiency particulate air (HEPA) filters to capture dust particles down to 2 microns. The system also includes an automatic dust sensor that monitors air quality in real-time, ensuring that the AQI remains below 50 and the dust level is consistently below 1 mg/m³.

Innovation in Maintenance: To maintain this efficient dust removal system, the textile mill employs a preventive maintenance strategy that involves regular inspections and cleaning of the HEPA filters. This approach not only extends the lifespan of the equipment but also reduces the overall energy consumption required for dust removal.

Energy Efficiency: The Jiangxi Textile Mill has demonstrated exceptional energy efficiency by reducing the amount of energy needed for dust removal. By implementing this system, the mill has saved over 30% on energy costs compared to traditional methods.

Community Impact: The success of the Jiangxi Textile Mill's dust removal program has had a positive impact on the local community. The improved air quality has contributed to healthier respiratory conditions among workers, while the reduced energy consumption has helped to reduce carbon emissions.

Conclusion: The Jiangxi Textile Mill's dedication to efficient dust removal has set a benchmark for other industrial facilities worldwide. Through innovative technology and proactive maintenance strategies, the mill has achieved remarkable results in maintaining a clean and healthy work environment. As more companies adopt similar approaches, we can expect to see further improvements in industrial hygiene practices across the globe.

江西纺织厂除尘背景介绍

江西纺织厂作为我国重要的纺织产业基地,在生产过程中面临着严重的粉尘污染问题,为了改善生产环境,提高产品质量和效率,江西纺织厂引入了先进的除尘技术,本文将围绕江西纺织厂除尘技术应用展开讨论。

江西纺织厂除尘技术应用案例

除尘设备介绍

江西纺织厂主要采用了高效脉冲袋式除尘器作为主要的除尘设备,该设备具有高效、环保、稳定等优点,能够有效地去除烟气中的粉尘颗粒,该设备还配备了自动监控系统,实时监测除尘效果,确保生产环境的清洁和稳定。

除尘工艺流程

江西纺织厂的除尘工艺流程主要包括原料准备、布料加工、织造、染整等环节,在每个环节中,都会对产生的粉尘进行收集和处理,在布料加工环节,通过高效脉冲袋式除尘器对布料进行除尘处理,将粉尘颗粒去除至较低水平。

案例分析

在具体应用中,江西纺织厂采用了多种先进技术手段,实现了高效除尘,该厂采用了智能控制系统,实现了对除尘设备的自动化控制,该厂还采用了高效滤料和滤网,提高了除尘效率,该厂还注重环保和节能,采用了低排放、低能耗的生产方式。

案例说明

为了更好地说明江西纺织厂除尘技术应用案例,我们可以使用英文表格进行补充说明,以下是英文表格:

江西纺织厂除尘技术应用案例说明

| 环节 | 除尘设备 | 除尘效果 | 技术手段 | 环保和节能措施 |

|---|---|---|---|---|

| 原料准备 | 高效脉冲袋式除尘器 | 高效去除粉尘颗粒 | 先进技术手段 | 低排放、低能耗 |

| 布料加工 | 自动监控系统实时监测 | 确保生产环境的清洁和稳定 | 自动控制 | 注重环保和节能 |

| 织造环节 | 其他除尘设备配合滤料和滤网 | 实现高效除尘和清洁生产 | 多重过滤和净化措施 | 低排放、低能耗、绿色生产方式 |

| 染整环节 | 其他除尘设备配合环保处理技术 | 实现染整过程中的粉尘控制 | 环保处理技术 | 注重环保和可持续发展 |

案例应用效果分析

江西纺织厂通过采用先进的除尘技术,实现了生产环境的清洁和稳定,该厂生产的纺织品质量得到了显著提高,同时也降低了生产成本和环境污染,该厂的环保和节能措施也得到了广泛认可和应用,江西纺织厂将继续加强环保和节能工作,推动纺织产业的高质量发展。

江西纺织厂在生产过程中引入了先进的除尘技术,实现了生产环境的清洁和稳定,该技术的应用不仅提高了纺织品的品质和效率,同时也降低了生产成本和环境污染,江西纺织厂将继续加强环保和节能工作,推动纺织产业的高质量发展,我们也应该加强对环保和节能工作的重视和支持,为我国的纺织产业发展做出更大的贡献。

Articles related to the knowledge points of this article:

Dual Thrusts:Innovation and Sustainability at the Du New Zhi Textile Mill

High Qing Textile Factorys History

The Textile Factory in Jiangxi:A Case Study of the Fabric Bags