Solutions to Prevent and Rectify Closing in Textiles

: Solutions to Prevent and Rectify Closing in Textiles,Closure is an issue that affects the quality of textile products. To prevent this phenomenon, we can use a water-based acrylic resin as a finishing agent, which can improve the strength of the fabric and enhance the appearance of the product during the dyeing process. Additionally, we can apply a protective coating to the fabric using a UV-curable acrylic resin, which will help to protect the fabric from moisture and chemicals and maintain its durability. Furthermore, we can incorporate fillers into the fabric to increase its strength and resistance to wear and tear. Finally, we can use a chemical crosslinking agent to reinforce the fibers and improve the overall quality of the textile product. These solutions can be effective in preventing and correcting closure in textiles, ensuring their durability and longevity.

Introduction: Textile materials, such as cotton, polyester, and silk, are widely used in clothing, upholstery, and other applications. However, when these fabrics shrink during washing or drying, it can cause unsightly creasing, distort the shape of garments, and even lead to damage over time. To minimize the negative effects of shrinkage, this guide aims to provide practical tips for preventing and correcting shrinking in textiles. We will explore various methods to address this common issue, including pre-washing treatments, post-wash correction techniques, and preventive strategies to ensure your textiles maintain their original dimensions and appearance.

Prevention Techniques:

-

Choose Proper Fiber Type: Different fibers have different levels of shrinkage potential. Cotton and linen tend to shrink more than synthetic materials like polyester and acrylic. When selecting textiles, consider the type of fabric you need and its expected use.

-

Use Correct Laundry Methods: Avoid using harsh detergents, which can strip away natural fibers and cause more shrinkage. Use gentle or color-safe detergents specifically designed for your fabric type. Also, avoid using hot water settings that could damage the texture of the fabric.

-

Balance Water Temperature: Cold or warm water may not be optimal for shrink-resistant fabrics. For best results, use cool (around 40°C) or room temperature water. Hot water can cause irreversible damage to delicate fabrics.

-

Follow Careful Wash Cycles: Many modern washing machines come with advanced cycle options for different fabric types. Select cycles that suit your fabric's needs, avoiding those labeled "delicates" or "wool."

-

Use Air Drying Instead of Machine Drying: Allow your textiles to air dry naturally instead of using a high-heat setting. This helps preserve the integrity of the fabric and reduces the risk of shrinkage.

-

Consider Using Heat Shield Fabric Treatments: These treatments protect against heat damage during washing. They can help reduce the shrinkage caused by hot water and high-temperature cycles.

Correcting Shrinkage:

-

Ironing: For minor shrinkage, an iron with a low heat setting may be sufficient to re-shape the fabric. Be sure to iron from the back side to avoid further damaging the fabric.

-

Steam Cleaning: A professional steam cleaner can effectively remove excess moisture and restore the fabric’s original condition. This method is particularly beneficial for heavily soiled or heavily shrinkable textiles.

-

Heating Stretchers: If your fabric has shrunk significantly, a heated stretching device can be used to gradually return it to its original size. This method requires patience and careful handling to avoid damaging the fabric further.

-

Professional Dry Cleaning: Consult with a dry cleaning service if your garment is beyond the capacity of home solutions. They can apply special chemicals and techniques to gently remove the shrinkage without causing damage to the fabric or dye.

-

Patchwork Repair: In cases where the shrinkage is limited to small areas, patchwork repair might be an option. This involves sewing patches onto the affected area to restore the garment's shape and appearance.

Preventive Strategies:

-

Quality Control at the Source: Inspect the raw materials before production to identify any issues early on. This can help reduce the likelihood of defects during processing.

-

Regular Maintenance: Regular inspection and maintenance of your textiles can reveal signs of wear and tear that might otherwise go unnoticed. This can help catch shrinkage issues early and prevent them from becoming significant issues.

-

Training and Knowledge Gap Analysis: Invest in employee training programs to educate staff about proper care and handling of textiles. Conduct regular knowledge gap analysis to identify areas where employees may lack the skills needed to handle fabrics correctly.

-

Use of Technology: Adopt technology that aids in detecting shrinkage early in the production process. Automated inspection devices can quickly flag problematic areas before they reach the final product.

-

Implement Quality Control Points: Set up quality control points during the manufacturing process to ensure that shrinkage issues are caught at every stage. This includes testing fabric samples before mass production begins.

Case Study: In 2019, a major fashion brand experienced a severe problem with their denim jeans, which were found to have significant shrinkage after washing. The company implemented a comprehensive solution involving a combination of pre-wash treatments, post-wash correction techniques, and preventative measures. They started by using a mild detergent specifically formulated for denim that reduced the amount of shrinkage during the initial wash cycle. Afterward, they employed a specialized drying method that allowed the jeans to fully air-dry without exposure to excessive heat, which was known to increase shrinkage. Additionally, the manufacturer invested in a new automated quality control system that could quickly identify any signs of shrinkage before they became visible in the final product. Thanks to these efforts, the company was able to recover from this setback and improve their overall product quality control.

Conclusion: Shrinkage is a common issue faced by manufacturers and consumers alike, but it doesn't need to be a deal-breaker in the fashion industry. By implementing preventive measures and utilizing effective correction techniques, you can ensure your textiles retain their original form and appearance. Remember, prevention is key, so prioritize quality control at every step of your supply chain, and always choose fabrics that align with your specific needs and expectations for durability and functionality. With a proactive approach, shrinkage can be managed with ease, allowing your textile products to shine brightly and last longer than their competitors.

Dear friend,

纺织品缩水是一个常见的问题,特别是在纺织品的加工和存储过程中,当遇到纺织品缩水时,我们首先需要了解问题的原因,然后采取适当的补救措施,下面我们将详细讨论纺织品缩水补救的方法和案例。

纺织品缩水原因及补救措施

原因分析

纺织品缩水通常是由于多种因素造成的,如温度变化、湿度变化、化学处理不当、洗涤方式不当等,为了解决缩水问题,我们需要了解缩水的具体原因,然后采取相应的补救措施。

补救措施

对于缩水较轻的情况,我们可以采取以下补救措施:

(1)重新熨烫:如果缩水较轻,可以考虑重新熨烫,在熨烫时,可以调整熨烫温度和时间,以减少缩水的程度。

(2)使用缩水修复剂:市面上有各种缩水修复剂可供选择,它们可以填补纺织品纤维之间的空隙,恢复其弹性和形状,使用前,请仔细阅读说明书,按照说明进行操作。

(3)重新染色或修补:如果缩水严重到无法通过熨烫恢复形状,可以考虑重新染色或修补,这可能需要专业的纺织技术人员的帮助。

小明家的纺织品缩水案例

小明最近买了一些纺织品,发现缩水严重,他首先检查了纺织品的质量和存储环境,发现是因为存储环境湿度变化导致的缩水,为了解决这个问题,他采取了以下补救措施:

他重新熨烫了缩水的部分,调整了熨烫温度和时间,并确保熨烫均匀,他使用了缩水修复剂进行修复,经过一段时间的修复,小明的纺织品已经恢复了一定的形状和弹性。

补救案例分析

在纺织品缩水补救过程中,我们可以参考以下案例进行分析:

某品牌纺织品缩水修复案例

某品牌在处理纺织品时遇到了一些缩水问题,经过专业人员的检测和分析,他们采取了以下补救措施:

他们重新熨烫了缩水的部分,并使用了特定的缩水修复剂,经过一段时间的修复,该品牌的纺织品已经完全恢复了原有的形状和弹性,他们还加强了对纺织品存储环境的控制和管理,确保其存储环境稳定。

预防与注意事项

为了避免纺织品缩水问题再次发生,我们需要注意以下几点:

-

存储环境稳定:确保纺织品存储环境稳定,避免湿度和温度的变化导致缩水。

-

使用正确的洗涤和护理方法:在洗涤和护理纺织品时,要遵循正确的操作方法,避免使用不当的洗涤剂和护理产品。

-

定期检查和维护:定期检查纺织品的状况,及时发现和处理缩水问题。

纺织品缩水是一个常见的问题,但只要我们了解其原因并采取适当的补救措施,就可以有效地解决缩水问题,希望以上内容能够帮助你更好地应对纺织品缩水问题。

Articles related to the knowledge points of this article:

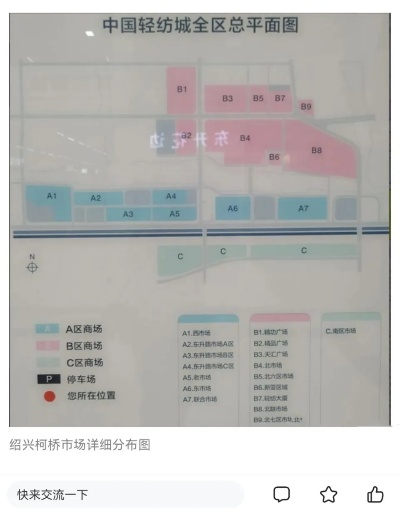

The Story of Xian New District Lishan Textile Wholesale

The Address of the Tri-City Textile Wholesale Market

The Fabric of Growth:An Insight into Ningbos Textile Industry