Printed Textiles:A Global Industrys Journey to the Print Press

"Printed Textiles: A Global Industry's Journey to the Print Press" is a comprehensive analysis of how the printing industry has transformed over the years, from its humble beginnings with primitive presses and hand-stitched garments to becoming a global industry. This transformation has been fuelled by advancements in technology, particularly in the area of digital printing, which have enabled faster, more efficient production methods.,The paper delves into the evolution of printing techniques, highlighting key milestones such as the introduction of lithography, screen printing, and dye sublimation. It also explores the impact of globalization on the industry, with an emphasis on the rise of multinational companies and the emergence of new markets for printed textiles.,The paper concludes with a discussion on the future of the industry, emphasizing the need for continued innovation and investment in research and development to stay ahead of the competition and cater to the changing demands of consumers.

In today's fast-paced world, printed textiles have become an indispensable part of our everyday lives. They range from casual wear like t-shirts and jeans, to functional items such as curtains and upholstery. The industry behind these textiles is a vast one, with a history that dates back thousands of years. It involves various steps, from raw material procurement to final product distribution, each step requiring precision and attention to detail. In this essay, we will explore the journey of printed textiles from its humble beginnings to becoming a global industry with the use of tables and case studies.

The genesis of printed textiles can be traced back to ancient civilizations, where patterns were often etched into fabric using natural inks like wax or soot. As technology advanced, the use of machines to produce printed textiles began to replace hand-painted patterns. In the mid-20th century, the development of the printing press revolutionized the industry, making it possible for textile manufacturers to mass-produce intricate designs. This marked the beginning of what we now know as the printed textile industry.

Today, there are several types of printed textiles used around the world. Here is a table summarizing some of the most common types:

| Type of Printed Textiles | Description |

|---|---|

| Digital Printing | Uses computer-generated images to create printed designs on textiles. This method allows for high-resolution prints and customization of designs. |

| Screen Printing | Employs a screen coated with a dye or pigment to transfer the design onto the fabric. This method is versatile and can produce large-scale prints. |

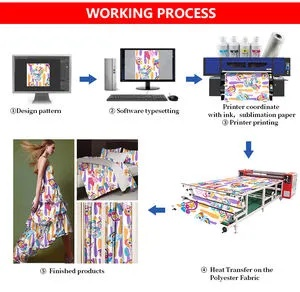

| Sublimation Printing | Uses heat to transfer a graphic onto the fabric surface, resulting in a permanent imprint. It's commonly used for garments like T-shirts and blankets. |

| DTG (Digital Heat-Transfer) | Similar to sublimation printing, but uses digital technology to control the temperature and speed of the heat source. This makes it easier to handle intricate shapes. |

One notable case study is the rise of "fast fashion" in China. With low-cost labor and efficient supply chains, China became a major player in the global printed textile market. However, this growth has come at a price: increased environmental impact, lower quality products, and a lack of innovation. To address these issues, many companies are now investing in sustainable practices and developing new technologies to improve the production process.

Another area of interest is the use of eco-friendly materials in printed textiles. Sustainability has become a buzzword in the industry, and companies are increasingly seeking out materials that are not only visually appealing but also have a positive impact on the environment. For example, organic cotton and recycled polyester are two popular options. By reducing waste and using renewable resources, companies can not only reduce their ecological footprint but also appeal to consumers who value sustainability.

Despite these advancements, the printed textile industry faces several challenges. One of the biggest challenges is the competition from other textile materials like knits and wovens. These materials offer different textures and finishes that can appeal to different customers. Additionally, the rising cost of raw materials, such as cotton and polyester, has put pressure on businesses trying to maintain profit margins.

Despite these obstacles, the future of printed textiles looks promising. As technology continues to advance, we can expect even more sophisticated methods of creating designs and even self-repairing textiles that last longer and require less maintenance. Moreover, with increased consumer awareness about the environmental consequences of fashion, sustainable practices will become even more important for businesses looking to succeed in this industry.

In conclusion, printed textiles represent a fascinating intersection of art, science, and commerce. From the humble origins of ancient civilizations to today's global industry, the industry has come a long way. By exploring the details involved in each step of the printing process and examining case studies like those mentioned above, we can gain a deeper understanding of this fascinating industry. As the world becomes more conscious of the impact of our consumption choices, it is likely that printed textiles will continue to play an important role in shaping our daily lives.

随着科技的进步和人们对美观、舒适度需求的提高,打印纺织品逐渐成为市场上的新宠,本篇文章将围绕打印纺织品展开讨论,通过案例分析、图表解释等方式,帮助大家深入了解这一新兴产业。

打印纺织品概述

-

定义与分类 打印纺织品是通过数字技术将图案、颜色、纤维等信息直接打印在织物上,从而形成具有独特外观和性能的纺织品,根据不同的打印技术,可分为热转印纺织品、喷墨纺织品等。

-

应用领域 打印纺织品广泛应用于服装、家居装饰、户外用品等领域,在服装领域,打印纺织品可以制作各种时尚服装,如印花T恤、印花连衣裙等;在家居装饰领域,打印纺织品可以制作窗帘、地毯等;在户外用品领域,打印纺织品则可用于帐篷、背包等。

案例分析

热转印纺织品案例

(1)产品介绍 某品牌的一款热转印运动衫,采用特殊的纤维材料和印花技术,使得运动衫具有透气、舒适的特点。

(2)制作过程 热转印技术是通过高温将图案直接打印在织物上,无需使用涂料或其他粘合剂,整个制作过程简单快捷,适合大规模生产。

喷墨纺织品案例

(1)产品介绍 某品牌的一款喷墨印花床单,采用环保纤维和喷墨技术,使得床单具有吸湿、抗菌的特点。

(2)优势特点 喷墨技术可以精确控制图案和颜色,使得印花床单具有高精度的图案和颜色效果;环保纤维的使用也符合现代人们对环保的需求。

打印纺织品技术说明

-

数字打印技术 数字打印技术是一种基于数字图像处理的打印技术,可以通过计算机软件将图案、颜色等信息直接打印在织物上,数字打印技术具有高精度、高效率的特点,适用于大规模生产。

-

特殊纤维材料的选择与应用 在选择特殊纤维材料时,需要考虑纤维的强度、吸湿性、抗菌性等因素,还需要根据打印的图案和颜色选择合适的纤维材料和工艺,某些特殊纤维材料具有较高的吸湿性和抗菌性,可以用于制作具有特殊功能的打印纺织品。

实践应用与注意事项

-

实践应用场景 打印纺织品的应用场景非常广泛,包括服装、家居装饰、户外用品等领域,在实践应用中,需要注意以下几点:选择合适的纤维材料和工艺,确保打印效果;注意环保和安全,避免使用有害物质;注意生产过程中的质量控制,确保产品质量。

-

注意事项 在实践应用中,需要注意以下几点:选择可靠的打印设备和技术;注意打印过程中的温度和时间控制,避免过度加热或烧焦;注意保护环境,避免浪费资源和污染环境。

打印纺织品是一种新兴的纺织材料,具有独特的外观和性能,通过案例分析、图表解释等方式,我们可以更好地了解打印纺织品的特点和应用领域,在实践应用中,需要注意选择合适的纤维材料和工艺,注意环保和安全等方面的问题,还需要不断探索和创新,推动打印纺织品的普及和发展。

Articles related to the knowledge points of this article:

Textile Fabric Care and Cleaning Solutions

A Class of Textiles:The Fabric Revolution

Strategies for Successful Customized Fabrics and Apparel Sales in Guangxi