The Role and Application of Textile Detackling Agents in Zhejiang

In the context of textile detackling in Zhejiang, textural agents play a pivotal role in enhancing product quality and reducing environmental impact. These agents, typically derived from natural sources such as bamboo or wood fibers, are designed to neutralize excess acetic acid and other chemical residues that can occur during the dyeing process, thereby preventing discoloration and improving the overall brightness and uniformity of the fabric. In addition, their eco-friendly nature allows for reduced use of harsh chemicals, making them an attractive option for sustainable manufacturing practices. As demand for eco-friendly materials increases, textile detackling agents in Zhejiang are poised to gain even more recognition as key players in the transition towards more sustainable fashion practices.

I. Introduction to Textile Detackling Agents

Textile detackling agents are a crucial component for the textile industry, specifically in Zhejiang where cotton is predominantly grown. These agents are designed to enhance the quality of cotton fabric by removing excess natural oils and waxes, which can cause stains on clothing. By doing so, they improve the aesthetic appeal, reduce maintenance costs, and increase the durability of textile products.

II. Types of Textile Detackling Agents

There are several types of textile detackling agents available in the market, each with its unique properties and benefits. Here is a brief explanation of some common types:

A. Chemical Detackling Agents

- Sodium Lauryl Alkylate (SLA): Sodium lauryl alkylate is a widely used chemical agent that works by breaking the interfacial bonds between cotton fibers and waxes, thereby removing them.

- Sodium Dodecyl Benzoate (SDB): Sodium dodecyl benzoate is an alternative to SLA and works similarly, but it's less harsh on the environment compared to SLA.

- Sodium Trichloroacetate (STAC): STAC is effective in removing wax from cotton but has a lower environmental impact than SLA.

B. Natural Detackling Agents

- Sunflower Oil: Sunflower oil, rich in fatty acids, is commonly used as a natural detackling agent. It helps in reducing the amount of wax buildup on fabrics.

- Castor Oil: Castor oil, derived from the seeds of the castor bean, is also a natural detackling agent that can be used as a substitute for chemical agents.

C. Enzymatic Detackling Agents

- Proteinase Kinase: This enzyme-based detackling agent breaks down waxy substances within the cotton fibers, resulting in cleaner fabrics without harsh chemicals.

- Cellulase: Cellulase is another type of proteinase that can break down cell wall structures, aiding in removing waxes from cotton.

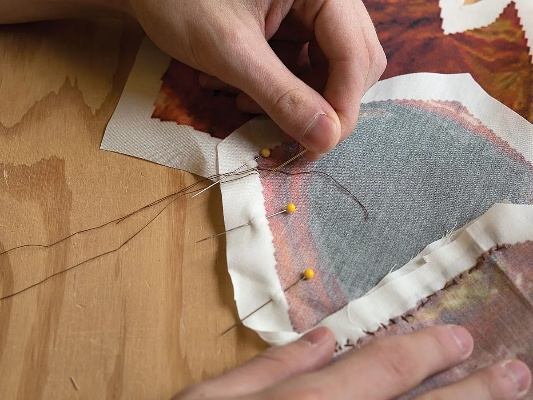

III. Application Methods and Techniques

The application methods and techniques used for textile detackling agents vary depending on the specific agent and the fabric type being treated. Here are some examples:

A. Chemical Detackling Agents: These agents are generally applied directly into the fabric or onto the surface of the fabric using a brush or spray applicator. They need to be thoroughly mixed with water before use to ensure optimal performance.

B. Natural Detackling Agents: Sunflower oil and castor oil are typically applied to the fabric by dipping or rubbing the fabric into the oil. The amount of oil applied depends on the severity of the wax buildup, and it's essential to follow the manufacturer's instructions for best results.

C. Enzymatic Detackling Agents: Proteinase kinase and cellulase are often applied topically to the fabric or even incorporated into the fabric itself during manufacturing processes. The enzymes work by breaking down the waxy substances, which then wash off with the washing process.

IV. Importance of Textile Detackling Agents in Zhejiang

The importance of textile detackling agents in Zhejiang lies not just in their ability to improve the quality of fabrics but also in their contribution to sustainable development goals. Here are some reasons why these agents are critical in the region:

A. Environmental Sustainability: Textile detackling agents are eco-friendly alternatives to traditional chemicals that may contain harmful additives. By replacing these chemicals with natural and enzymatic agents, manufacturers can minimize their environmental footprint and contribute towards greener production practices.

B. Cost Savings: Using detackling agents instead of chemical treatments can result in significant cost savings over time, especially if the reduction in maintenance and repair costs due to reduced wax buildup is substantial.

C. Product Durability: Textile detackling agents help to prolong the lifespan of fabrics by preventing excessive wear and tear caused by wax buildup. This means that garments made with treated fabrics will last longer, reducing waste and contributing to circular economy principles.

V. Case Studies

To demonstrate the practical applications of textile detackling agents in Zhejiang, let's examine two case studies:

Case Study 1: A local textile company in Hangzhou uses a blend of chemical and natural detackling agents to treat cotton fabrics for export markets in Europe. By using a combination of SLA and sunflower oil, the company was able to meet stringent environmental regulations while still improving the aesthetic appeal of the fabrics. The company reported a significant reduction in maintenance costs and improved customer satisfaction, ultimately increasing its market share in the European market.

Case Study 2: An apparel brand in Ningbo has implemented a comprehensive approach to textile detackling, incorporating both enzymatic and chemical agents into their production process. The company found that integrating these agents not only enhanced the quality of their fabrics but also led to a reduction in waste generated from excessive wax removal. As a result, the brand experienced a decrease in product returns and increased customer loyalty. This case study underscores the synergistic effects of using different types of textile detackling agents in a holistic approach to textile treatment.

VI. Future Development of Textile Detackling Agents

Looking ahead, there's a promising future for textile detackling agents in Zhejiang, driven by advancements in technology, sustainability concerns, and consumer preferences. Here are some potential developments:

A. Advanced Technology: Advancements in nanotechnology could lead to new materials that are more effective and safer to use, potentially eliminating the need for harsh chemicals altogether. For instance, nanoparticles engineered to interact specifically with waxes might offer a non-chemical approach to removing waxes while maintaining the quality of the fabric.

B. Environmental Innovations: The growing focus on sustainability means that companies looking to adopt new technologies must consider how their practices align with environmental goals. This could include developing biodegradable detackling agents that are less damaging to the environment and easier to dispose of after use.

C. Consumer Preferences: As consumers become more aware of the environmental impact of textile products, they will demand more sustainable solutions. Companies need to keep pace with consumer trends by offering products that prioritize environmental friendliness and longevity rather than just appearance and convenience.

In summary, the future of textile detackling agents looks bright, as it combines technological progress, environmental consciousness, and consumer preferences to create a more efficient, eco-friendly approach to fabric care.

浙江作为纺织业的重要省份,纺织品的质量和清洁度一直是关注的焦点,为了有效解决纺织品脱绒问题,浙江地区开发了一种新型的纺织品脱绒防治剂,本文将详细介绍该防治剂的用途及其在实际应用中的案例。

浙江纺织品脱绒防治剂的主要用途

- 防止纺织品脱绒:该防治剂主要用于防止纺织品在生产过程中出现脱绒现象,提高纺织品的清洁度和质量。

- 提高纺织品的性能:通过使用该防治剂,可以改善纺织品的透气性、吸湿性、柔软性等性能,提高纺织品的使用价值和舒适度。

浙江纺织品脱绒防治剂的具体应用案例

某纺织厂使用脱绒防治剂的成功案例

某纺织厂在生产过程中发现纺织品经常出现脱绒现象,给生产效率和产品质量带来了不小的影响,为了解决这一问题,该厂采用了浙江纺织品脱绒防治剂,经过一段时间的使用,该厂发现脱绒现象得到了有效控制,产品质量得到了显著提高,该厂还发现使用该防治剂后,纺织品的透气性和吸湿性得到了明显改善,提高了纺织品的舒适度。

脱绒防治剂在特殊材料上的应用案例

在某些特殊材料如丝绸、羊毛等纺织品上,脱绒防治剂也表现出良好的效果,这些特殊材料在使用过程中容易出现起毛、起球等问题,使用脱绒防治剂可以有效防止这些问题,提高材料的品质和外观。

浙江纺织品脱绒防治剂的成分和特点

- 主要成分:该防治剂主要含有防脱绒成分和表面活性剂等,这些成分能够有效地渗透到纺织品纤维内部,破坏绒毛结构,从而达到防止脱绒的目的。

- 特点:该防治剂具有高效、环保、易操作等特点,它能够快速渗透到纺织品纤维内部,减少脱绒现象的发生;该防治剂还具有很好的环保性,不会对环境造成污染,在使用过程中,该防治剂的操作也相对简单方便。

英文案例说明

英文案例一:某纺织厂使用浙江纺织品脱绒防治剂的详细情况

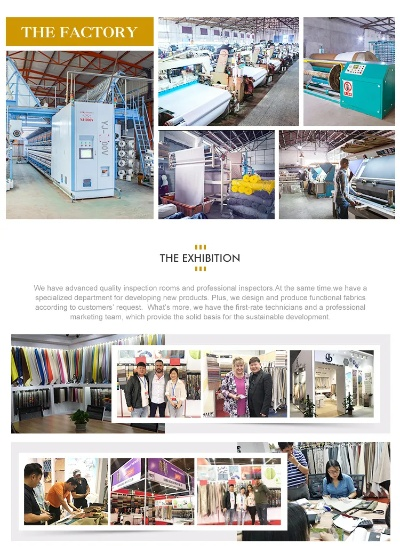

A textile mill in Zhejiang province has successfully used a new type of lint removal agent to prevent and treat the problem of lint loss in their textiles. This mill has observed significant improvements in the quality and cleanliness of their textiles due to the agent's effectiveness in preventing lint loss. Additionally, the agent has also improved the performance of the textiles, such as their breathability, moisture absorption, and softness, providing better usage value and comfort for the products.

英文案例二:脱绒防治剂在特殊材料上的应用案例的详细情况

In particular, there are cases where lint removal agents have shown good results on special materials such as silk or wool. These special materials often experience problems such as lint shedding and balling during production, which can have a significant impact on production efficiency and product quality. However, the use of lint removal agents has effectively prevented these problems, resulting in improved product quality and appearance.

Articles related to the knowledge points of this article:

The Uniqueness of Textiles from Hunan Province

Emerging Fabric Technologies and Innovations from Zhejiang,China

Exploring the Future of Environmentally Friendly Textiles in Guangxi,China