纺织品验布操作流程

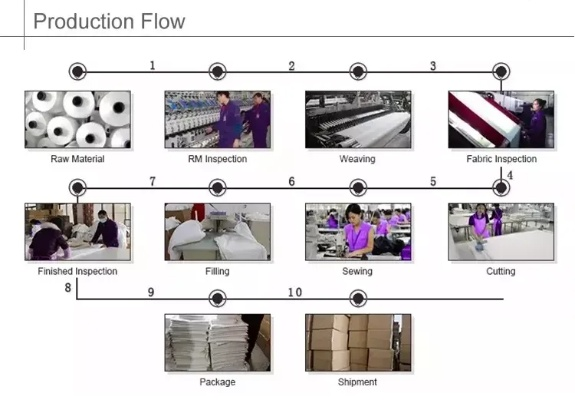

The process of textile inspection and sorting involves a series of steps to ensure that the quality of the fabric meets the standards required for use. The following is an outline of the key stages in this operation:,1. Inspection: The first stage is to visually assess the raw material. This includes examining the texture, color, and overall appearance of the fabric. Any defects or irregularities are noted down for further analysis.,2. Sorting: Once the fabric has been inspected, it is placed into appropriate categories based on its intended use. For example, clothing fabrics may be sorted by type (cotton, wool) or weight (lightweight, heavyweight).,3. Handling: Fabrics are carefully handled to prevent damage during the inspection and sorting process. This may involve rolling, folding, or stacking the fabric to allow easy access to all sides without causing wear or tear.,4. Testing: Depending on the specific requirements of the project, the fabric may undergo various testing procedures such as dye resistance tests, dimensional stability assessments, and flame retardant testing to ensure compliance with safety and performance standards.,5. Packaging/Labeling: Once the fabric has passed all necessary tests, it is packaged according to specifications and labeled clearly indicating its intended purpose, quality grade, and other relevant information.,Overall, the objective of the textile inspection and sorting process is to provide high-quality, safe, and reliable materials for end consumers, ensuring that they meet the expectations of both industry standards and individual customer requirements.

Welcome to the world of textile inspection, where every piece of fabric is meticulously assessed for quality, defects, and consistency. In this guide, we will delve into the essential steps that go into the process of conducting a thorough examination on various types of fabrics. Whether it's cotton, polyester, or any other material, our checklist will ensure that your production runs smoothly without compromise on quality or efficiency.

Before diving into the technicalities of the process, let’s first establish the basics of what we’re looking for when inspecting textiles. A successful checklist should include the following key components:

Pre-inspection

The pre-inspection phase involves gathering all necessary information about the fabric before it goes under the microscope. This includes:

- Fabric Information: The name, brand, type, color, weight, and dimensions of each piece.

- Manufacturer Data: Documentation regarding manufacturing processes, materials used, and any relevant certifications.

- Packaging and Shipping Details: Any special handling requirements or environmental conditions in which the fabric was stored prior to inspection.

Inspection Tools and Equipment

To ensure accurate measurements and assessments, the appropriate tools and equipment must be selected:

| Item | Purpose | Description |

|---|---|---|

| Microscope | To examine minute details like thread count, texture, and color uniformity | Useful for identifying flaws, discolorations, and irregularities |

| Scalpel | Used to gently remove samples for more thorough examination | Prevents damage to the fabric during sampling |

| Tweezers | For delicate or small items that need precise grasping | Enhances accuracy in picking up and handling samples |

| Tape measure | To measure length and width for comparison with standardized dimensions | Helps in ensuring consistency and comparability across different batches |

Sample Collection

The collection process should be as systematic as possible to avoid bias and errors:

| Phase | Actions |

|---|---|

| Random selection | Ensure an unbiased selection of samples from different areas and thicknesses |

| Sampling technique | Use sterile tools and techniques to minimize contaminants or damage |

| Size and quantity | Ensure enough samples are taken for statistical analysis and future reference |

| Labeling and storage | Label each sample accurately with its location, date of collection, and the specific area of concern |

Testing Methods

Once collected, each sample undergoes a series of tests to evaluate its quality:

| Method | Purpose |

|---|---|

| Weighing | Measures the density and weight of the fabric to ensure uniformity and consistency |

| Color Matching | Determines if the colors are consistent across the entire batch |

| Texture Assessment | Checks for any irregularities in texture or surface structure |

| Strength Testing | Evaluates the durability and strength of the fabric |

| Dye Dispersion Test | Assesses the evenness of dye application to ensure uniformity of appearance |

Reporting Results

Upon completion of the testing, results must be recorded and presented in a clear and concise manner:

| Report Content | Explanation |

|---|---|

| Summary Table | Comprehensive listing of findings and recommendations |

| Analysis & Diagnosis | Detailed explanation of the test results and any identified issues |

| Quality Grade | Assigning a grade to the fabric based on its performance |

| Recommendations | Outlining potential solutions or next steps for improvement |

In conclusion, the textile inspection process is an intricate dance between precision, detail, and critical thinking. By following a structured approach, you can ensure that every fabric piece meets the highest standards of quality and consistency. Remember, good preparation leads to effective outcomes – always start with thorough planning and meticulous execution.

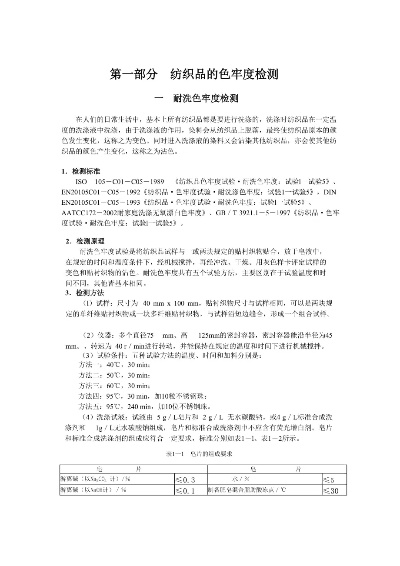

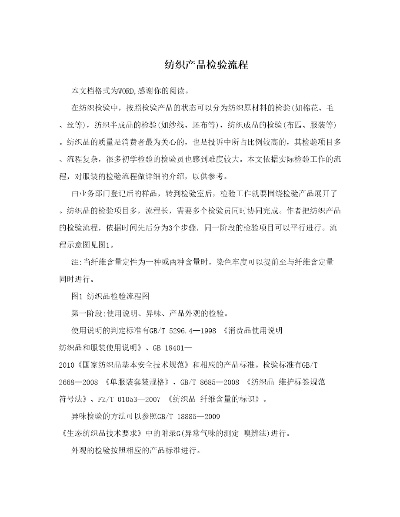

在纺织品生产过程中,验布环节至关重要,它确保了产品的质量与标准,本篇将详细介绍纺织品验布的操作流程,并结合实际案例进行说明。

纺织品验布流程

准备工作

(1)检查设备:确保验布机、验布仪器等设备处于正常工作状态。 (2)材料准备:准备好待验布料、标准样品以及相关检验标准文件。

验布操作步骤

(1)检查布料外观:观察布料颜色、纹理、疵点等,确保无异常。 (2)预处理:根据布料材质和工艺要求,进行必要的预处理。 (3)验布测试:进行各项验布测试,如密度测试、缩水率测试、色牢度测试等。 (4)记录数据:详细记录各项测试数据,为后续分析提供依据。

注意事项

(1)操作规范:严格按照验布操作流程进行,确保检验结果的准确性。 (2)安全防护:穿戴防护服、手套等个人防护用品,确保操作安全。 (3)质量控制:确保检验过程符合质量标准,避免出现质量问题。

实际案例说明

以某纺织品公司为例,其纺织品验布操作流程如下:

准备工作

该公司在验布前需检查设备是否正常工作,并准备好待验布料、标准样品以及相关检验标准文件,公司还制定了详细的验布操作流程和安全防护措施。

验布操作步骤

(1)外观检查:检查布料外观,确保无疵点、无杂质。 (2)预处理:根据布料材质和工艺要求,进行必要的预处理,如涂胶、加固等。 (3)密度测试:使用密度测试仪对布料进行密度测试,确保符合标准要求。 (4)缩水率测试:使用缩水率测试仪对缩水处理后的布料进行缩水率测试,确保缩水处理效果符合标准。 (5)色牢度测试:对布料进行色牢度测试,确保颜色持久、不易褪色,公司还制定了严格的检验标准,确保检验结果符合质量要求。

英文表格补充说明

以下是纺织品验布操作流程的英文表格补充说明:

| 步骤 | 描述 | 英文说明 |

|---|---|---|

| 准备工作 | 检查设备 | Check equipment for normal operation |

| 材料准备 | 待验布料、标准样品及检验标准文件 | Materials required for inspection |

| 验布操作步骤 | 外观检查 | Check appearance of fabric |

| 预处理 | Preparation according to fabric material and process requirements | |

| 验布测试 | 密度测试 | Density test of fabric |

| 缩水率测试 | Washing shrinkage test of fabric | |

| 色牢度测试 | 记录数据 | Record test data for color fastness |

| 注意事项 | 操作规范 | Operational regulations |

| 安全防护 | 安全防护用品 | Personal protective equipment for safety |

| 质量控制 | 质量标准符合性 | Quality control to ensure compliance with quality standards |

纺织品验布操作流程是确保纺织品质量的重要环节,在实际操作中,应严格按照流程进行,同时注意安全防护和质量控制,以确保检验结果的准确性,以上内容仅供参考,如需更多信息,建议查阅相关文献或咨询纺织行业专业人士。

Articles related to the knowledge points of this article:

Top Textile Companies Websites

Textile Seam Flaw Detection:A Case Study

Navigating the Global Market:The Price Landscape of Luo Lei Textiles