The Role of Sulfur in Textile Production:An Overview

In the realm of textile production, sulfur plays a vital role in enhancing the quality and performance of fabrics. This chemical element, derived from natural sources like coal, is widely used in the manufacture of various textiles, including cotton, wool, and synthetic fibers such as polyester. Sulfur is crucial in the dyeing process for creating vibrant colors on textiles, aiding in the formation of strong, durable bonds between fibers, and improving the overall feel and texture of the fabric. Additionally, sulfur-containing additives are incorporated into certain types of yarn to enhance its flame resistance properties, which is particularly important in industries that deal with high-risk materials or environments. As technology continues to advance, researchers continue to explore new applications for sulfur in textile production, aiming to create even more sustainable and efficient methods for producing high-quality fabrics.

Introduction to Sulphur-based Textile Additives

Sulfur, a non-metallic element, is an essential component in various industries, including textile manufacturing. In the textile industry, sulphur plays a crucial role in enhancing the properties of fibers and fabrics. This article will explore the use of sulfur-based additives in textile production, their benefits, and some practical applications. We'll also present an example case study to illustrate how these additives are used in real-world situations.

Types of Sulfur-Based Textile Additives

There are several types of sulfur-based textile additives that are commonly used in the industry. Here’s a brief overview:

-

Sulfur Dioxide (SO2): SO2 is a gaseous compound that reacts with water to form hydrogen sulfide (H2S). It is commonly used as a dehydrating agent in textile dyeing processes.

-

Ammonium Sulfate ((NH4)2SO4): Ammonium sulfate is a salt that is often used in conjunction with SO2 to enhance the fixation of dyes in fibers.

-

Sulfur Acid (H2SO4): Sulfuric acid is a strong acid that can be used as a pretreatment agent to improve the wettability of fibers before dye application.

-

Sodium Sulfide (Na2S or NaHS): Sodium sulfide is used as a desulfurizing agent to remove excess sulfur from fabrics.

Benefits of Sulfur-based Textile Additives

The main advantage of using sulfur-based textile additives is their ability to enhance the dyeability of fibers. By incorporating these additives into the dye bath, the dyes have better affinity for the fiber surface, resulting in brighter colors and improved durability. Additionally, sulfur-based additives can improve the washfastness of fabrics by reducing the amount of loose dye particles on the fabric surface during washing.

Practical Applications of Sulfur-based Textile Additives

In practice, sulfur-based textile additives are widely used in the following applications:

-

Dyeing: These compounds are often used in the dyeing process as intermediates or final products. For instance, SO2 is often added as a dehydrating agent to enhance the dye fixation process in textile manufacturing.

-

Pretreatment: Sulfuric acid can be used as a pretreatment agent to improve the wettability of fibers before dye application. This helps in achieving a uniform distribution of dye throughout the fabric.

-

Desulfurization: Sodium sulfide is used as a desulfurization agent to remove excess sulfur from fabrics. This reduces the occurrence of yellow discoloration and improves the overall appearance of clothing and textile products.

Example Case Study - Sulfur-based Textile Additives in Real-world Scenario

One example of the practical application of sulfur-based textile additives can be seen in the manufacture of polyester shirtings. During the dyeing process, SO2 is commonly added to enhance the dye fixation in polyester fibers. This not only results in brighter and more vibrant colors but also improves the washfastness of the fabrics.

Another example can be found in the treatment of cotton fabrics for garments that require special attention to color fastness. In this case, Sodium sulfide is used to remove any residual sulfur from the fabric before dyeing. This ensures that the fabric retains its original color after washing and drying.

Conclusion

The use of sulfur-based textile additives is essential for the quality and performance of textile products. These additives help improve the dyeability of fibers, enhance the washfastness of fabrics, and reduce the occurrence of yellowing and discoloration. In real-world scenarios, these additives are widely used in the dyeing process, as well as in pretreatment and desulfurization steps. As such, it's crucial for manufacturers to understand the benefits and practical applications of these additives to ensure that they meet the demands of consumers and maintain the integrity of their products.

纺织品硫化铵简介

纺织品硫化铵是一种重要的纺织化学品,广泛应用于印染、织造、染整等多个领域,它是一种高效、环保的硫化剂,能够显著提高纺织品的耐洗、耐皱性能,同时还能赋予纺织品独特的色泽和质感。

纺织品硫化铵的种类与特性

-

种类:纺织品硫化铵主要分为有机硫化铵和无机硫化铵两种类型,有机硫化铵通常含有有机胺基团,具有更好的耐洗性能和柔软性;而无机硫化铵则具有较高的耐热性和稳定性。

-

特性:

(1)提高耐洗性能:纺织品硫化铵能够显著提高纺织品的耐洗性能,延长使用寿命。

(2)改善织物结构:纺织品硫化铵能够改善织物的结构,提高织物的弹性和透气性。

(3)赋予色泽和质感:纺织品硫化铵能够赋予纺织品独特的色泽和质感,使纺织品更加美观。

纺织品硫化铵的应用案例

印染行业的应用

在印染行业中,纺织品硫化铵被广泛应用于各种面料的生产,某品牌的高档棉质面料采用了纺织品硫化铵进行处理,使其具有更好的耐洗性能和柔软性,同时也赋予了面料独特的色泽和质感,这种面料受到了消费者的高度认可,销售量持续攀升。

织造行业的应用

在织造行业中,纺织品硫化铵也被广泛应用于各种纤维的织造,某些新型纤维的织造过程中,使用纺织品硫化铵处理可以提高纤维的强度和耐磨性,同时还可以改善织物的结构,使其更加柔软舒适,纺织品硫化铵还可以与其他化学物质协同作用,提高织物的环保性能。

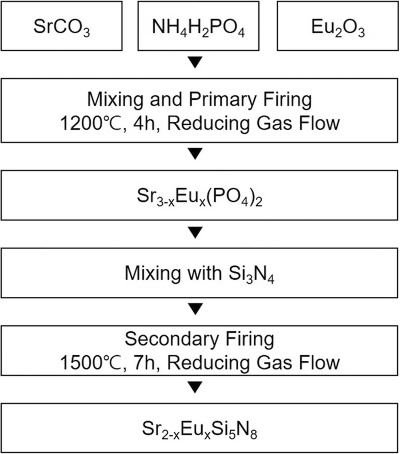

纺织品硫化铵的生产与制备方法

纺织品硫化铵的生产主要采用化学合成法或物理加工法,化学合成法通常使用有机胺类化合物与硫源进行反应,生成纺织品硫化铵,物理加工法则是在高温高压条件下,通过物理方法将硫源与纺织品进行反应,生成纺织品硫化铵。

纺织品硫化铵的测试与评估方法

-

测试方法:对纺织品硫化铵进行测试时,主要测试其耐洗性能、柔软性、色泽和质感等方面的指标,还需要对产品的环保性能进行评估。

-

评估方法:可以通过实验测试、外观评估等方式对纺织品硫化铵进行评估,实验测试可以观察纺织品在洗涤过程中的变化情况,评估其耐洗性能;外观评估可以观察产品的色泽和质感,评估其美观程度,还可以通过环保性能测试仪对产品的环保性能进行评估。

纺织品硫化铵作为一种重要的纺织化学品,具有广泛的应用前景,它能够显著提高纺织品的耐洗性能、改善织物结构、赋予色泽和质感等优点,纺织品硫化铵的生产与制备方法简单易行,产品性能稳定可靠,在应用案例中,纺织品硫化铵在印染、织造等多个领域都有着广泛的应用前景,随着纺织行业的不断发展,纺织品硫化铵的应用将会更加广泛和深入。

Articles related to the knowledge points of this article:

The Art of Fabrics:A Journey through the World of帆里纺织品

Textile Industry in Global Perspective

The Art of Textiles:Unveiling the Fabric of Quality

1.品牌A,全球知名内衣品牌,以其高品质、时尚设计和创新技术闻名。该品牌注重面料选择和工艺制作,注重舒适性和透气性

High Yang Famous Textile Brands:A Review of Specialty Stores