Threading Through the Tough:The Saga of Textile Repair in a Textile Mill

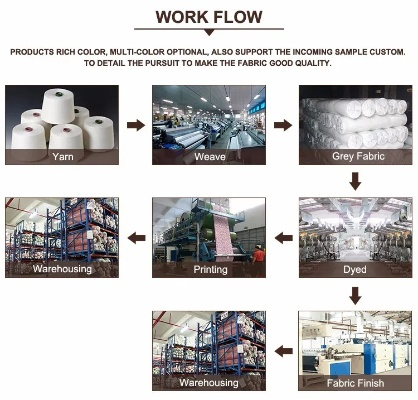

"Threading Through the Tough: The Saga of Textile Repair in a Textile Mill",In this article, we will explore the complex and challenging world of textile repair within a textile mill. Textiles are an essential component of our lives, from everyday clothing to high-end fashion accessories. However, with the passage of time, textile materials can become damaged, leading to a decline in product quality, reduced aesthetic appeal, and potential health hazards.,As a result, textile repair has become essential for maintaining the integrity and durability of these materials. This process involves identifying the type and extent of damage, selecting appropriate repair materials and techniques, and applying them to the affected areas of the textile.,The challenges faced in textile repair are numerous. Firstly, the complexity of the materials involved means that it is often difficult to determine the exact cause of damage. Additionally, the delicate nature of many textiles makes it challenging to apply new materials without causing further damage. Furthermore, the need for precision in repair operations requires a high level of skill and experience, which may be lacking in some repair facilities.,Despite these challenges, the importance of textile repair cannot be understated. By investing in effective repair methods, textile mills can maintain their competitive edge and ensure the continued production of high-quality products.,In conclusion, threading through the tough of textile repair within a textile mill is a complex but critical task that requires expertise, patience, and dedication. With careful attention to detail and a commitment to excellence, textile mills can continue to thrive and provide consumers with beautiful, durable fabrics they can rely on for years to come.

Introduction: In the bustling world of textile manufacturing, where machines churn out billions of fabric items each year, there is an often overlooked but crucial aspect of this industry - textile repair and restoration. At the heart of these efforts are the skilled artisans who work tirelessly to mend and restore damaged or worn-out textiles. In this article, we will delve into the challenges faced by these workers, the tools they use to perform their tasks, and how they contribute to maintaining the integrity of the textile industry.

Challenges Faced by Textile Workers: Textile repair is not only physically demanding but also intellectually taxing. Workers often face numerous obstacles when attempting to restore damaged textiles. Firstly, they must identify the extent of damage and assess its impact on the overall quality and functionality of the item. This requires a keen eye for detail and a deep understanding of the fabric's properties. Secondly, they must select the appropriate tools and materials for repair, ensuring that they do not further damage the textile in question. For instance, using too much force while ironing can cause permanent damage. Thirdly, they need to follow precise techniques to ensure the repaired area blends seamlessly with the original fabric. This requires patience, attention to detail, and years of training.

Tools and Materials Used in Textile Repair: The tools used by textile workers for repair vary depending on the type of damage and the desired outcome. Common tools include a needle, thread (of various weights and colors), scissors, pins, iron, and steamer. Depending on the severity of the damage, workers may also use specialized glues or adhesives to bond the repaired area to the original fabric. Additionally, they may need to use specialized cleaning agents to remove any dirt or grime from the surface before starting the repair process.

Case Study: One notable example of successful textile repair is the restoration of a vintage dress. The dress, once owned by a renowned fashion designer, had suffered extensive wear and tear over the years. The workers at the textile mill were tasked with repairing the dress, restoring its original beauty and style. Using a combination of traditional hand-sewn techniques and modern machinery, they carefully removed any loose threads or frayed edges, then rewoven the remaining fabric using high-quality cotton yarn. They applied a special dye that matched the original color of the dress, ensuring that the repaired areas blended seamlessly with the rest of the fabric. The result was a stunning piece of vintage clothing that had been brought back to life with precision and care.

Conclusion: The textile repair industry plays a vital role in preserving the legacy and value of our cultural heritage. By working tirelessly to mend and restore damaged textiles, these workers help to keep these treasures alive for future generations to enjoy. Their dedication, creativity, and expertise make them essential members of the global textile industry. As we continue to produce more and more textile products, it is important that we recognize and appreciate the hard work and skills of our textile repair workers. Thank you for tuning in to this episode of "Threading Through the Tough: The Saga of Textile Repair in a Textile Mill."

Dear reader,

最近在纺织厂工作,织补工作确实让人感到疲惫不堪,我想分享一下在纺织厂工作的日常感受和心得。

纺织厂织补工作的日常

在纺织厂,织补工作是一项繁重而充满挑战的任务,每天早晨,工人们早早地来到车间,开始了一天的工作,他们需要仔细检查每一件织品,寻找破损的地方,然后进行修补,在这个过程中,他们需要掌握各种织补技巧和材料知识,以确保修补后的织品既美观又耐用。

织补工作的辛苦与累累

织补工作虽然辛苦,但每一件修补后的织品都让人感到满足和成就感,每当看到一件破损的织品经过修补变得焕然一新,工人们都会感到无比的喜悦和满足,织补工作也确实是一项体力活,需要长时间的劳动和专注,特别是在炎热的夏天或寒冷的冬天,长时间的劳动更是让人感到疲惫不堪。

案例分析

为了更好地理解纺织厂织补工作的实际情况,我们可以参考一些案例进行分析,有一位老工人分享了他多年的织补经验,他说:“在纺织厂工作,最让人感到累的是长时间的工作和高强度的劳动,每当看到一件件破损的织品经过我们的努力得到修复,那种成就感是无法用言语表达的。”

英文案例说明

在纺织行业,有许多成功的案例可以说明纺织厂织补工作的艰辛与成就,某家大型纺织厂采用了先进的织补技术,大大提高了织品的修复率和耐用性,他们通过不断学习和创新,提高了工作效率和质量,同时也提高了工人们的劳动体验,他们还注重员工的培训和职业发展,为员工提供了良好的工作环境和福利待遇,这些成功的案例不仅展示了纺织厂的实力和实力,也为其他纺织企业提供了借鉴和参考。

总结与建议

纺织厂织补工作是一项既辛苦又充满成就感的工作,虽然需要长时间的劳动和高强度的体力劳动,但每一件修补后的织品都让人感到满足和成就感,为了更好地支持纺织行业的发展和员工的职业发展,我们建议企业加强员工的培训和职业发展,提供良好的工作环境和福利待遇,我们也应该注重技术创新和设备升级,提高织品的修复率和耐用性,我们才能更好地满足市场需求和提高企业的竞争力。

就是关于纺织厂织补工作的英文口语化内容,希望这篇文章能够为您提供一些帮助和启示,如果您有任何其他问题或需要更多的信息,请随时告诉我。

Articles related to the knowledge points of this article:

Exploring the History and Impact of Baicheng Tongyu Textile Factory

The Chemical Treatment in Textile Factory:药膏的使用与案例分析

Breaking Barriers:A Day in the Life of Women at Changle Textile Factory

The Transformative Journey of the Original Pulp Factory,Chzhou Textile Mill