Fabrics on the Rise:An Analysis of the Recent Surge in Textile Inventory

"Fabrics on the Rise: An Analysis of the Recent Surge in Textile Inventory",In recent years, textile inventory has experienced a significant surge, with a notable increase in demand for fabrics. The reasons behind this surge are multifaceted and complex. Firstly, there has been a growing awareness of environmental concerns, which has led to a shift towards sustainable and eco-friendly materials. This trend has resulted in an increase in demand for natural fibers and recycled fabrics, as well as a decline in synthetic materials. Secondly, advancements in technology have enabled manufacturers to produce higher-quality fabrics at lower prices. This has made them more attractive to consumers, who are willing to pay a premium for superior quality. Thirdly, there has been an increase in demand for fashion trends, which have influenced the types of fabrics that are produced. Finally, there has been a shift towards more personalized and customizable products, which has increased demand for fabrics with unique designs and patterns. Overall, the recent surge in textile inventory can be attributed to a combination of factors, including environmental concerns, technological advancements, fashion trends, and consumer preferences.

Introduction: As the global economy continues to evolve, textile industries have been facing a complex landscape. One trend that has emerged is an upward trend in textile inventory levels. This phenomenon, driven by various factors such as changing consumer preferences, increased production capacity, and economic growth, has significant implications for both manufacturers and retailers. In this article, we will delve into the reasons behind the recent surge in textile inventory and examine how it affects various stakeholders in the industry. We will also provide insights into potential solutions and strategies for mitigating future challenges.

Reasons Behind the Increase:

-

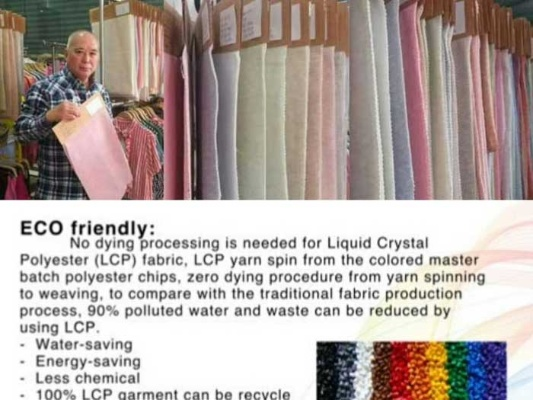

Consumer Preferences: A shift towards sustainable and eco-friendly textiles has led to higher demand for products made from recycled or organic materials. This has resulted in an increase in the volume of textiles being produced and stored.

-

Increased Production Capacity: The COVID-19 pandemic has accelerated the adoption of remote work and online shopping, leading many factories to increase their production capacities. As a result, there has been a surge in textile inventory levels.

-

Economic Growth: The global economy has continued to grow, which has boosted consumer spending. As a result, there has been a rise in demand for textiles, leading to an increase in inventory levels.

-

Global Trade Policies: International trade policies have had a significant impact on the textile industry. Some countries have implemented policies aimed at reducing import tariffs, while others have tightened regulations on foreign investments. These policies have led to changes in supply chains and increased inventory levels.

Potential Impact on Manufacturers: The surge in textile inventory levels can have several negative impacts on manufacturers. Firstly, it can lead to overproduction and excess capacity, which can result in financial losses. Secondly, it can delay the delivery of goods to retailers, causing delays in cash flow and loss of customer trust. Thirdly, it can put pressure on manufacturers to reduce costs and increase efficiency, which may not always be possible.

Potential Impact on Retailers: Retailers, on the other hand, face a challenging situation due to the increased inventory levels. They need to manage stock levels effectively to avoid overstocking and obsolescence. Additionally, they need to ensure that their inventory aligns with changing consumer preferences and market trends.

Solutions and Strategies: To mitigate the effects of rising textile inventory levels, manufacturers and retailers must adopt effective strategies. Manufacturers can implement lean manufacturing techniques and optimize their production processes to reduce waste and increase efficiency. They should also explore alternative sources of raw materials to diversify their supply chain and reduce reliance on any one supplier.

Retailers, on the other hand, can leverage data analytics to better understand consumer behavior and make informed decisions about stocking levels. They should also invest in technology to streamline their supply chain management and reduce operational costs. Additionally, they can explore partnerships with manufacturers to jointly manage inventory levels and share risk.

Case Study: One example of the impact of rising textile inventory levels is the case of a major fashion retailer. In response to increased demand for sustainable fashion, the retailer launched a new collection of clothing made from organic cotton. However, the launch was marred by unexpectedly high inventory levels, resulting in significant financial losses and delays in cash flow. To overcome these challenges, the retailer partnered with a manufacturer specializing in producing sustainable textiles. Together, they developed a strategy for efficient inventory management and optimized their supply chain. This collaboration allowed the retailer to maintain its commitment to sustainable fashion while minimizing the risks associated with high inventory levels.

Conclusion: In conclusion, the increase in textile inventory levels is a complex phenomenon that affects manufacturers, retailers, and the entire industry. To mitigate its negative impacts, both manufacturers and retailers must adopt effective strategies such as lean manufacturing techniques, data analytics, partnerships, and technological innovation. By doing so, they can better manage their inventory levels and remain competitive in the ever-changing market landscape.

Recently,随着纺织品市场的繁荣,纺织品库存量呈现上升趋势,让我们一起来探讨这个主题,并从英文案例中获取更多信息。

背景介绍

纺织品库存上升的原因可能有很多,包括市场需求增加、新产品推出、季节性需求波动等,随着全球经济的复苏和消费者需求的多样化,纺织品行业面临着新的机遇和挑战。

英文案例分析

以下是一个英文案例,以供参考:

英文案例:

假设某纺织品公司最近面临纺织品库存上升的问题,据数据显示,近期该公司的纺织品销售量有所增加,同时新订单量也有所上升,这表明市场需求正在增长,同时也有新产品推出和市场需求的季节性波动等因素的影响。

主题讨论

市场趋势分析

随着全球经济的复苏和消费者需求的多样化,纺织品行业面临着新的机遇和挑战,随着技术的进步和消费者对环保、可持续性等要求的提高,纺织品行业也在不断发展和创新,纺织品库存上升是市场趋势的一部分。

库存上升原因分析

库存上升的原因可能有很多,包括原材料成本上升、生产效率提高、新产品推出等,季节性需求波动也可能对库存产生影响,在夏季销售旺季时,纺织品库存可能会相应增加;而在淡季时,市场需求可能相对较低,导致库存下降。

应对策略探讨

对于纺织品库存上升的问题,企业可以采取以下应对策略:

(1)优化生产计划:根据市场需求和库存情况,优化生产计划,提高生产效率,加强与供应商的合作,确保原材料供应的稳定性和及时性。

(2)加强市场调研:了解市场需求和消费者需求的变化,及时调整产品结构和销售策略,加强与经销商和零售商的合作,提高销售渠道的覆盖率和效率。

(3)采用先进技术:采用先进的生产技术和设备,提高生产效率和产品质量,降低生产成本,加强环保和可持续性方面的投入,提高产品的环保性和可持续性。

补充说明

为了更好地理解和应对纺织品库存上升的问题,我们可以使用英文表格进行补充说明:

英文表格:

| 因素 | 原因分析 | 应对策略 |

|---|---|---|

| 市场趋势 | 随着全球经济复苏和消费者需求的多样化 | 优化生产计划、加强市场调研、采用先进技术 |

| 库存上升 | 原材料成本上升、生产效率提高、新产品推出等 | 根据市场需求和库存情况,优化生产计划;加强与供应商的合作;采用先进技术 |

| 案例分析 | 某纺织品公司近期面临纺织品库存上升的问题 | 该公司在近期销售量增加的同时新订单量也有所上升;加强市场调研;采用环保和可持续性方面的投入 |

纺织品库存上升是市场趋势的一部分,企业需要从多个角度进行分析和应对,在优化生产计划、加强市场调研、采用先进技术等方面采取措施可以有效地应对纺织品库存上升的问题,企业还需要关注市场需求的变化和消费者需求的变化,及时调整产品结构和销售策略。

Articles related to the knowledge points of this article:

The Fabric of Heritage:Crafting the Future with Shaoxings Textiles

Navigating the World of Textiles:A Comprehensive Guide for Business Leaders