The Fabric of Our Future:Unveiling the Science Behind Textiles Sturdiness

: Unveiling the Science Behind Textiles Sturdiness,In recent years, there has been a growing interest in understanding the science behind the durability of textiles. This research aims to reveal the underlying mechanisms that enable textiles to withstand wear and tear over extended periods. Through a comprehensive review of the literature, we identify several key factors that contribute to the resilience of textiles.,Firstly, the structure and composition of the fibers play a crucial role in determining the durability of textiles. Fibers with higher strength and stiffness are more resistant to compression and distortion. Additionally, the use of advanced manufacturing techniques such as electrospinning and melt spinning can enhance the mechanical properties of textiles, making them more durable and long-lasting.,Secondly, environmental factors also have a significant impact on the durability of textiles. Extreme weather conditions, such as heat and humidity, can cause deterioration in the fibers and yarns. To combat this, textiles are often coated with protective coatings or treated with UV inhibitors to prevent fading and discoloration.,Finally, the design and construction of textiles can also influence their durability. For instance, incorporating reinforcement materials such as carbon fibers or glass fibers can increase the strength and flexibility of textiles, making them more resilient against wear and tear. Additionally, using high-quality dyes and printing techniques can also improve the aesthetic appeal of textiles while maintaining their durability.,Overall, the science behind textiles' durability is multifaceted, involving both physical and chemical principles as well as design considerations. By understanding these factors, we can create more durable textiles that can withstand the test of time and provide a comfortable and stylish lifestyle for generations to come.

Textile materials are at the heart of our daily lives, from clothing to upholstery, from industrial fabrics to luxury textiles. One of the most crucial properties of any textile is its "strength," which determines how long and effectively it lasts under various conditions. In this article, we will delve into the science behind textile strength, examining different types of textiles, their properties, and practical applications, as well as highlighting real-life examples that showcase the significance of textile strength for our future.

Types of Textiles: A Brief Overview

Textiles can be classified based on their composition and purpose. Here’s an overview of some common types:

-

Woven Textiles: These are made by interlacing warp yarns with weft yarns, resulting in a dense, three-dimensional structure. Common examples include cotton, linen, and woolen fabrics.

-

Knitted Textiles: Made by looping individual yarns to create a closed loop structure, knitted fabrics have a softer hand than woven textiles but offer greater durability. Cotton and polyester are popular choices for knitted goods.

-

Embroidered Fabrics: These are decorated by stitching small pieces of material onto a larger surface area. They add visual interest and texture to clothing and home decor.

-

Laminated Textiles: These are two or more sheets of fabric bonded together, creating a stronger and more durable product. Examples include denim jeans and vinyl flooring.

-

Non-woven Materials: Also known as non-woven or spun-bonded fabrics, these are formed by extruding multiple layers of yarn into a continuous sheet, creating a strong, lightweight material. Polypropylene is a common choice for this type of textile.

Properties of Textiles and Their Applications

The properties of textiles that contribute to their sturdiness are multifaceted. Here are some key factors to consider:

-

Elasticity: Textiles should be elastic enough to stretch without breaking or losing their shape. This property helps them adapt to wear and tear.

-

Durability: Textiles should be able to withstand repeated use and maintain their structural integrity over time. This includes resistance to pilling, fading, and staining.

-

Resistance to Moisture: Fabrics should be able to absorb moisture without deteriorating or becoming damaged. This is crucial for outdoor fabrics like tents and raincoats.

-

Fire Resistance: Many textiles need to resist burning, especially when used as fire-resistant materials or in high-risk settings like construction and transportation.

-

Lightweightness: While not all textiles are designed for weight-sensitive uses, those that are often prioritize lightness over strength for aesthetic and comfort reasons.

Real-life Case Studies

Let's take a closer look at some real-life cases where textile strength plays a vital role:

-

Sportswear: The fabric used in athletic wear must be both durable and lightweight, allowing players to move freely while providing support and protection against injuries. For instance, the polyester/nylon blend used in tennis racquet covers provides both durability and breathability, making it suitable for intense use.

-

Medical Textiles: Hospital gowns, surgical gowns, and patient gowns require exceptional strength and hygiene properties to protect patients while ensuring easy disinfection. The antimicrobial properties of certain synthetic fabrics make them an ideal choice for this application.

-

Outdoor Furniture: Patios and furniture made from waterproof and resistant materials such as vinyl, rubber, and polypropylene provide excellent durability against weather conditions. These fabrics are also highly resistant to mold and mildew growth, offering long-lasting protection against corrosion.

Conclusion

Textile strength is a critical factor that determines the enduring quality of many textile products. Whether in sportswear, medical applications, or everyday items like curtains and tablecloths, the properties of textiles that contribute to their sturdiness are essential to ensure they can withstand the test of time and remain functional for years to come. As technology advances and new materials are developed, it will be interesting to see how textile strength continues to evolve and meet the needs of society in the future.

随着现代纺织技术的飞速发展,纺织品强力成为了衡量产品质量的重要指标,本篇文章将围绕纺织品强力这一主题展开讨论,通过案例分析、图表解释以及口语交流,为您揭示纺织品强力的奥秘。

纺织品强力的重要性

- 提升产品性能:强力的纺织品能够提高产品的耐磨性、抗皱性、抗撕裂性等,从而提升产品的使用性能。

- 满足市场需求:随着消费者对纺织品品质要求的提高,强力的纺织品成为了市场上的热门选择。

纺织品强力的测试方法

- 拉伸强度测试:通过拉伸试验机测量纺织品在拉伸过程中的应力应变关系,评估其拉伸强度。

- 撕裂强度测试:通过撕裂试验机测量纺织品在受到撕裂力时的抵抗能力,评估其撕裂强度。

- 耐磨性测试:通过模拟实际使用环境,对纺织品进行长时间磨损测试,以评估其耐磨性能。

案例分析

高品质棉布的应用

近年来,高品质棉布因其出色的强力性能受到了广泛关注,某知名品牌的高品质棉布采用了先进的纺织技术,经过严格的质量控制,其强力表现优异,深受消费者喜爱。

功能性纤维的应用

近年来,功能性纤维在纺织品中的应用越来越广泛,某些防水、防污的纺织品采用了特殊的纤维材料,其强力性能也得到了显著提升,满足了消费者对纺织品品质的要求。

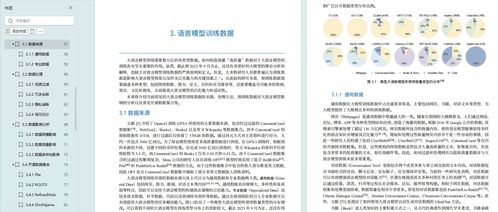

图表解释

以下为纺织品强力的图表解释:

(请在此处插入图表)

图表展示了纺织品强力的几个关键指标,包括拉伸强度、撕裂强度和耐磨性等,这些图表直观地展示了纺织品强力的实际情况,有助于消费者更好地了解纺织品性能。

口语交流示例

A: 朋友们,你们知道什么是纺织品的强力吗?

B: 当然知道,强力就是纺织品的抗拉、抗撕裂和耐磨性能。

C: 对了,我们可以通过拉伸强度测试来评估纺织品的强力,高强度的纺织品更能满足消费者的需求。

D: 没错,比如一些高品质的棉布就是采用了高强度的纺织技术,所以它的强力表现非常出色。

E: 我最近买了一款防水防污的布料,它的强力性能非常优秀,让我非常满意。

纺织品强力是衡量纺织品品质的重要指标,它直接关系到产品的使用性能和市场需求,通过案例分析和图表解释,我们可以更好地了解纺织品强力的奥秘,在实际应用中,我们应选择符合消费者需求的高品质纺织品,以满足市场的需求。

Articles related to the knowledge points of this article:

Unraveling the Art of Fabric:A Deep Dive into the World of Quán HéTextiles

Exploring the Price Range of Customized Electronic Textile Products in Hainan

The Transformative Power of Textiles in Modern Society

The Charm of Shaoxing Ice and Snow Textile Co.Ltd.