Textile Filtration Performance Testing Guide

This paper presents a comprehensive textile filter performance testing guide designed to evaluate the efficiency of fabric filters in various applications. The guidelines provide detailed procedures for conducting tests on filter materials, including their filtration properties, resistance to particle penetration, and resistance to clogging. ,The first section covers the testing methods used to determine filter performance, including methods such as permeability, porosity, and filtration efficiency tests. The second section discusses specific test parameters, including the selection of appropriate filter media and the determination of the pressure drop through the filter. ,The third section focuses on testing techniques for evaluating filter performance under real-world conditions, such as those found in industrial environments or in laboratory simulations. This section also includes considerations for selecting appropriate filter models and equipment, as well as recommendations for maintaining consistent test conditions. ,Overall, this guide provides a valuable resource for those interested in testing textile filters and evaluating their performance in different applications.

Introduction: The textile industry is an essential sector, with a vast array of products ranging from everyday wearables like shirts and socks to high-end fashion accessories such as shoes and bags. One crucial aspect that determines the quality of these products is the performance of the filter that keeps them clean and free from contaminants, including dust, bacteria, and other microorganisms. Therefore, it's important to understand how to properly perform textile filter testing to ensure that our clothing and accessories are safe for public use. In this guide, we will cover the essentials of textile filter testing methods, their significance, and how to interpret test results effectively.

Textile Filter Testing Methodologies: There are several methods for testing textile filters, depending on the intended application and the type of filter being tested. Here’s a brief overview of the most commonly used methods:

-

Air Permeability Testing (APT): This method measures the ability of fabrics to let air through under controlled conditions. The test is conducted in an enclosed chamber where air flows freely through the sample at a constant velocity. A standardized filter is installed on the surface of the sample, and the rate of air flow is measured as the filter is inserted.

-

Water Absorption Testing (WAT): This method assesses a fabric’s ability to absorb water droplets. It involves spraying water droplets onto the sample and measuring the time required for the droplets to spread out across the surface. Higher absorbency values indicate better filter efficiency.

-

Microbial Count Testing: This method counts bacteria or other microorganisms on textile samples. It involves placing the sample under sterile conditions and then inoculating it with a specific type of bacteria. The number of bacteria present on the sample is then counted and compared against a standard count to determine if the filter is effective at preventing contamination.

-

Static Pressure Testing (SPT): This method measures the static force needed to push a filter material against a surface, indicating its filtration capability. It’s useful in determining whether a filter can trap large particles effectively.

-

Electrostatic Charge Testing: This technique checks for any charge build-up on the fabric surface after exposure to certain materials or chemicals, which might interfere with the effectiveness of a filter.

-

Chemical Resistance Testing: This method tests a filter against chemical solutions or solvents, assessing how well it resists damage caused by various chemicals.

Importance of Filtration Tests: Performing proper textile filter testing not only ensures product safety but also contributes to consumer confidence and market acceptance. Filters that pass these tests are more likely to be accepted by regulatory bodies and end consumers alike. Moreover, they can improve the longevity of textile products, reducing waste and providing a higher level of comfort and hygiene for those who use them regularly.

Case Study: Consider a hypothetical scenario where a textile company was manufacturing high-quality antimicrobial sportswear for athletes. To ensure that their filters were up to standard, the company decided to conduct comprehensive testing on all their filters using both APT and WAT methods. The results showed that their filters had excellent air permeability and good absorption capabilities. However, they also found some issues with resistance to certain chemicals and electrostatic charge build-up. After analyzing these results, the company made necessary adjustments to optimize their filter technology, resulting in improved performance across all categories tested. As a result, the company increased sales significantly and received positive feedback from customers who appreciated the enhanced quality and safety of their sportswear.

Conclusion: In conclusion, textile filter testing plays a vital role in ensuring that our clothes and accessories remain safe for public use. By understanding the different types of filters and the significance of each test, companies can optimize their filter performance and meet stringent regulatory standards. It's important for everyone involved in the textile industry to invest in proper testing procedures and to stay updated on the latest trends and regulations to maintain a competitive edge in the market.

纺织品过滤性能检测概述

随着现代工业的快速发展,纺织品在日常生活和工业生产中的应用越来越广泛,为了确保纺织品的质量和性能符合标准,对其过滤性能进行检测是至关重要的,本文将详细介绍纺织品过滤性能检测的方法、流程以及案例分析。

检测方法与流程

方法介绍

纺织品过滤性能检测主要包括以下几个步骤:样品准备、实验操作、数据分析等,实验操作是关键环节,包括对样品进行预处理、选择合适的过滤介质和参数设置等。

(1)样品准备

检测前,需对样品进行预处理,确保其满足实验要求,样品应具有代表性,能够反映实际使用情况。

(2)实验操作

在实验过程中,需严格按照相关标准操作规程进行,选择合适的过滤介质,如纤维、膜片等;设定合适的过滤参数,如过滤速度、过滤精度等;进行过滤实验,观察并记录实验结果。

(3)数据分析

实验结束后,对实验数据进行整理和分析,通过数据分析,可以了解纺织品过滤性能的优劣,为后续使用提供参考。

流程说明

(1)样品采集:从市场或实验室中采集符合标准的纺织品样品。

(2)实验室测试:将样品送至实验室进行过滤性能检测。

(3)数据分析:通过图表、数据等方式展示实验结果,并进行深入分析。

案例分析

以某品牌纺织品为例,对其过滤性能进行案例分析,该品牌纺织品采用高质量纤维材料制作而成,具有较高的过滤性能,以下是该案例的分析过程:

样品采集与预处理

该品牌从市场上采集了一批符合标准的纺织品样品,经过清洗、烘干等预处理步骤,确保样品满足实验要求。

实验操作与参数设置

在实验室测试过程中,选用合适的过滤介质(如纤维膜片),设定合适的过滤参数(如过滤速度、过滤精度等),通过反复试验,最终确定了最佳的过滤参数组合。

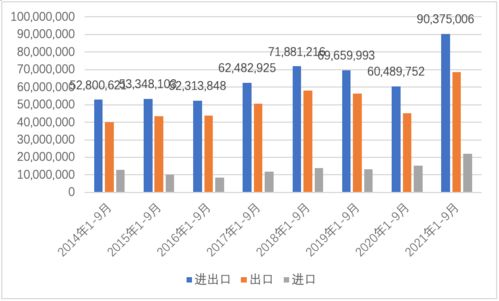

数据分析与结果展示

根据实验结果,该品牌纺织品具有较高的过滤速度和较低的阻力,通过图表展示了实验数据,直观地反映了纺织品过滤性能的优劣,还进行了深入的分析,探讨了影响纺织品过滤性能的因素,为后续生产提供了参考。

结论与建议

通过本次纺织品过滤性能检测,可以了解到该品牌纺织品的过滤性能情况,根据检测结果,该品牌纺织品在过滤速度、过滤精度等方面表现优异,具有较高的市场竞争力,也提出了以下建议:加强产品质量控制,提高纤维材料的质量和性能;加强技术创新,开发更多高性能的纺织品;加强市场推广,提高品牌知名度和美誉度。

总结与展望

纺织品过滤性能检测是确保纺织品质量的重要手段之一,本文介绍了纺织品过滤性能检测的方法、流程以及案例分析,也提出了加强产品质量控制、加强技术创新和市场推广等方面的建议,随着纺织工业的不断发展,纺织品过滤性能检测将更加重要和必要。

Articles related to the knowledge points of this article:

Functional Textiles:A Comprehensive Study

High-End Fashion Trends with Lanlan Textiles

Navigating the Global Market:The Price Landscape of Luo Lei Textiles