Understanding the Standards for Textile Testing:An Overview

This paper presents an overview of the standards used for textile testing. It begins by defining what textiles are and how they are tested, before detailing the various types of standard that are used in this field. It then discusses the different aspects covered in these tests, such as color, texture, and durability, as well as the importance of compliance with these standards. Finally, it explores the benefits and challenges associated with implementing these standards, and provides some suggestions for those seeking to improve their textile products through better testing methods. Overall, the paper aims to provide a comprehensive understanding of the standards used for textile testing, helping readers to better understand the industry and how to meet its requirements.

I. Introduction to Textile Testing Standards Textile testing standards serve as a benchmark for ensuring the quality, durability, and safety of textile products. They are designed to provide uniformity in testing methods, materials, and results across different industries, countries, and regions. These standards are essential for consumers, manufacturers, and regulatory bodies alike. In this section, we will discuss the importance of textile testing standards and how they impact the industry.

II. Textile Testing Standards and Their Purpose Textile testing standards define the criteria that textile products must meet in order to be considered safe and effective. These standards cover a wide range of parameters, including color, texture, tensile strength, tear resistance, water absorption, shrinkage, and more. By establishing these standards, manufacturers can ensure that their products meet industry-wide requirements and comply with regulations set by governments and organizations.

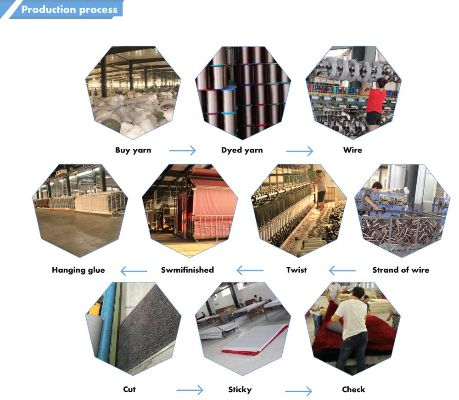

III. Textile Testing Methods and Procedures There are several types of textile testing methods and procedures used to evaluate product performance and quality. Some of the most common methods include:

- Color test: This method is used to measure the intensity and purity of a product's colors.

- Tensile test: This test determines the breaking strength of a fabric or textile material.

- Tear test: This method evaluates the ability of a product to withstand tearing forces.

- Water absorption test: This test measures how much water a product can absorb before it wrinkles.

- Shrinkage test: This method assesses the extent to which a textile material contracts when exposed to heat or chemicals. Other methods may include flame test, abrasion test, and flammability test, among others.

IV. Textile Testing Standards Comparison When comparing different textile testing standards, it is essential to consider factors such as the type of product being tested (e.g., clothing, home furnishings, industrial equipment), the purpose of testing (e.g., consumer protection, quality assurance), and the regulatory environment in which the product is produced and sold. For example, some standards might focus on color accuracy while others prioritize durability and resistance to wear and tear. It is crucial for manufacturers to choose appropriate standards that align with their products' intended use and target market.

V. Case Study: The Implementation of a New Textile Testing Standard A recent case study highlights the successful implementation of a new textile testing standard in the garment industry. This standard was developed by a group of international experts who recognized the need for greater uniformity and transparency in textile product testing. The new standard includes detailed guidelines for measuring color accuracy, tensile strength, and other important parameters. As a result of this standard, manufacturers were able to improve their product quality and enhance customer trust by providing clear information about the materials and processes used in their garments.

VI. Challenges and Considerations for Manufacturers Manufacturers face several challenges when implementing textile testing standards, including:

- Limited resources: Manufacturers may have limited funds or expertise for conducting thorough testing and compliance audits.

- Time constraints: Complying with multiple standards can be time-consuming and costly.

- Changes in regulations: Regulatory requirements can change rapidly, making it difficult for manufacturers to keep up with all the latest standards. To address these challenges, manufacturers should:

- Collaborate with testing laboratories to streamline testing processes and reduce costs.

- Train staff members on the latest standards and techniques to ensure compliance.

- Stay informed about changes in regulations and adapt to them proactively.

VII. Conclusion Textile testing standards are critical for maintaining quality and safety in the textile industry. By understanding these standards and their purposes, manufacturing companies can better ensure the safety and reliability of their products. Additionally, by comparing different standards, manufacturers can choose those that best align with their product line and target market. As the global textile industry continues to evolve, it is essential that manufacturers stay updated on the latest testing standards to stay competitive and meet consumer demands.

随着纺织行业的快速发展,纺织品的质量和安全性越来越受到人们的关注,为了确保纺织品的质量和安全,制定了一套实用的纺织品检测标准是非常必要的,本篇文章将围绕纺织品检测实用标准展开讨论,并结合实际案例进行说明。

纺织品检测实用标准概述

检测目的

纺织品检测的目的是确保纺织品符合国家或行业标准,保障消费者的使用安全,主要包括纤维含量、颜色、光泽、织物结构、有害物质含量等方面的检测。

检测方法与流程

(1)样品采集:根据检测需求,采集符合标准的纺织品样品。 (2)样品预处理:对样品进行必要的清洗、整理等处理。 (3)化学分析:使用各种检测仪器和方法对样品进行化学分析,包括纤维成分分析、染色牢度测试、有害物质含量检测等。 (4)外观质量评估:通过观察、手感等方式评估样品的外观质量。 (5)报告出具:根据检测结果出具检测报告。

案例分析

以某知名品牌纺织品为例,其检测流程如下:

(1)样品采集:从市场上购买符合标准的纺织品样品。 (2)样品预处理:清洗样品,去除杂质。 (3)化学分析:使用纤维成分分析仪和染色牢度测试仪等设备进行纤维成分和染色牢度测试,检测样品中是否存在有害物质,如重金属、有机污染物等。 (4)外观质量评估:通过手感、外观照片等方式评估样品的外观质量。 (5)出具检测报告:根据检测结果出具详细的检测报告,明确纺织品的质量和安全情况。

案例说明

某知名品牌的一款纺织品在市场上广受欢迎,其检测流程如下:

- 样品采集:该品牌从市场上购买了一批符合标准的纺织品样品。

- 样品预处理:清洗样品,去除杂质,确保样品符合检测要求。

- 化学分析:使用先进的纤维成分分析仪和染色牢度测试仪等设备进行检测,经过检测,该品牌纺织品的主要纤维成分符合国家标准,且染色牢度测试合格,该样品中不存在有害物质,如重金属、有机污染物等。

- 外观质量评估:通过观察样品外观,发现该品牌纺织品颜色鲜艳、光泽度高,织物结构均匀,符合优质纺织品的标准,该品牌还提供了详细的检测报告,为消费者提供了可靠的购买依据。

纺织品检测实用标准的应用实例

- 国家行业标准的应用实例:根据国家相关行业标准,对纺织品进行检测,确保其符合国家安全标准,对于某些特殊用途的纺织品,需要进行特殊处理和测试,以确保其安全性和可靠性。

- 企业内部标准的应用实例:企业可以根据自身生产需求和质量控制要求,制定自己的纺织品检测标准,对于某些特殊材质的纺织品,需要进行特殊的测试和分析,以确保其性能和质量符合要求。

- 实际应用案例分析:在实际应用中,纺织品检测实用标准的应用范围广泛,在服装行业中,纺织品的质量和安全性直接关系到消费者的使用体验和健康安全;在化妆品行业中,纺织品的质量和安全性也是非常重要的因素之一,纺织品检测实用标准的制定和应用对于保障产品质量和安全具有重要意义。

纺织品检测实用标准是保障纺织品质量和安全的重要手段,在实际应用中,我们应该根据不同行业和不同需求制定适合自己的纺织品检测标准,并严格按照标准进行检测和分析,我们还需要不断加强纺织品检测技术的研发和应用,提高纺织品检测的准确性和可靠性,为保障产品质量和安全提供更加有力的支持。

Articles related to the knowledge points of this article:

The New Standard for Textile Heavy Metal Limitations