Dry-Settings in Textile Production:Science,Benefits,and Applications

"Dry-Settings in Textile Production: Science, Benefits, and Applications.",In the realm of textile science, dry-setting is a crucial process that involves the use of chemicals to set or harden the fibers in woven fabrics. This technology offers several advantages over traditional wet-setting methods, including improved product durability, reduced water waste, and enhanced energy efficiency. The science behind dry-setting is complex, involving the interplay between chemical reactions, temperature control, and fiber properties. The benefits of dry-setting include increased dimensional stability, improved colorfastness, reduced shrinkage, and enhanced resistance to pilling and wrinkling.,The application of dry-setting technology in textile production has expanded beyond the realm of apparel to include industrial fabrics, upholstery materials, and even carpets. Its use has revolutionized the way we produce and consume textile products, offering a sustainable alternative to traditional manufacturing processes that rely heavily on water resources. As demand for sustainable and eco-friendly textiles continues to grow, the role of dry-setting technology in meeting this need is becoming increasingly important.Exploring the Art of Luoyuan Textile Dry-Setting Techniques: A Comprehensive Guide to Optimizing Performance and Enhancement

In the world of textile production, the process known as 'dry-setting' is a crucial step in enhancing the quality and durability of fabrics. Attention must be given to every detail in this delicate art, from choosing the right materials to ensuring optimal drying conditions. In this guide, we will delve into the intricacies of Luoyuan's textile dry-setting techniques to understand their significance and how they can be optimized for maximum performance enhancement. Let us explore the science behind dry-setting, the benefits it brings to the garment industry, and the practical applications that have made it a household term in the industry.

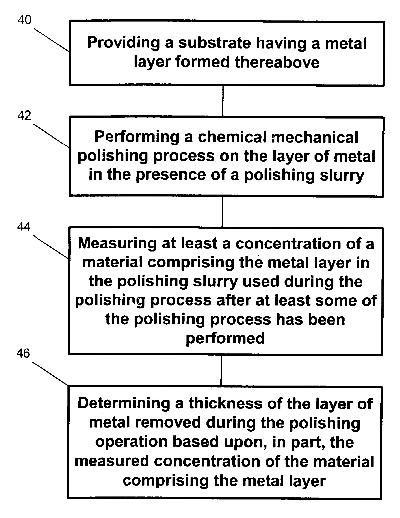

Dry-settings are essential processes used in textile manufacturing to impart permanent creaseless or reduced crease properties on woven fabrics. These settings involve using chemicals or heat to alter the fiber structure of the fabric, making it more stable and resistant to creasing or wrinkling. Here's a brief overview of the science behind dry-setting:

- Chemical Dry-Setting (Chemical Dyes): This method involves using chemicals to fix dyes onto the fibers. The chemical reactions create a stronger bond between the dye and fabric, resulting in a more durable finish.

- Heat Dry-Setting (Embroidery Heat Stamping): In this method, heat is applied to the fabric through an embossing machine. This process causes the fibers to contract, creating ridges or raised patterns on the surface. This results in a textured appearance that adds depth and interest to the fabric.

- Dye Sublimation Dry-Setting: This technique uses sublimation printing to apply color directly onto the fabric. As the fabric dries, the dye molecules evaporate, leaving behind permanent color on the fibers.

The primary benefit of dry-setting is its ability to enhance the durability of fabrics. When done correctly, dry-settings make fabrics less prone to creasing and wrinkling, making them ideal for high-wear environments like sportswear, outdoor gear, and formal wear. Additionally, dry-setting provides excellent color retention, ensuring vibrant colors do not fade over time.

Now let's take a closer look at some practical applications of Luoyuan's textile dry-setting techniques:

Luoyuan Textile Manufacturing Company: Luoyuan Textile has been utilizing dry-setting techniques in their production processes for several years now. Their latest product line features a collection of clothing items with enhanced durability and reduced creasing properties. For instance, their shirts undergo a specific dry-setting treatment that makes them highly resistant to creasing and wrinkling, even after repeated washings.

Dry-Setting in Fashion Design: Dry-setting plays a crucial role in fashion design as well. Many designers incorporate this technique into their designs to create a distinct textured aesthetic. By using dry-setting, designers can achieve a unique texture that adds depth and character to their garments, making them stand out in the market.

Dry-Settings in Hospitality Industry: Hotels and restaurants often rely on fabrics with reduced creasing properties for their guest rooms and dining areas. Luoyuan's textiles have proven to be a reliable choice in these industries due to their exceptional durability and resistance to wrinkling.

Dry-Setting in Sportswear: Sports apparel manufacturers use dry-setting to ensure their products meet the rigorous standards of professional athletes. With increased demand for performance-driven sportswear, manufacturers need textiles that are both comfortable and durable. Luoyuan's textiles meet these requirements, making them popular choices among sportswear brands.

In conclusion, dry-setting techniques are integral to the success of any textile manufacturing business. From enhancing durability to adding texture, dry-setting offers a wide range of benefits that cater to various industry sectors. Luoyuan Textile stands out in its commitment to excellence, utilizing advanced dry-setting techniques to produce textiles that exceed customer expectations. As the demand for high-quality textiles continues to grow, Luoyuan's expertise in dry-setting will undoubtedly play a significant role in shaping future trends and innovations in textile production.

罗源,作为我国纺织业的重要基地,其纺织品干定型工艺备受关注,本篇将围绕罗源纺织品干定型为主题,从多个角度进行深入探讨,结合案例分析,使读者更直观地了解这一工艺。

罗源纺织品干定型概述

罗源纺织品干定型工艺主要涉及纺织材料的预处理、干燥过程以及后续定型处理,该工艺注重对纤维的均匀处理和定型效果的控制,确保纺织品在后续加工过程中具有良好的性能和外观。

工艺流程及关键步骤

- 原料准备:选用高质量的纺织材料,确保纤维质量。

- 预处理:对纤维进行软化处理,提高纤维与基材的粘合度。

- 干燥过程:通过控制温度和时间,使纤维达到理想的干燥状态。

- 定型处理:采用特定的设备和技术,对干燥后的纺织品进行定型处理。

案例分析

以某知名罗源纺织品生产企业为例,详细介绍其干定型工艺流程和关键步骤,该企业采用先进的设备和技术,严格控制干燥温度和时间,确保纺织品在达到理想的干燥状态的同时,保持优良的定型效果,该企业还注重对纤维的均匀处理和质量控制,确保纺织品具有优良的物理性能和外观。

工艺特点与优势

- 工艺特点:工艺流程简洁、高效,注重对纤维的均匀处理和定型效果的控制。

- 优势:采用先进的设备和技术,提高生产效率和质量;严格控制干燥条件,确保纺织品具有良好的性能和外观;注重环保和可持续发展,符合现代纺织工业的发展趋势。

随着科技的不断进步和人们对纺织品品质要求的提高,罗源纺织品干定型工艺将会得到更广泛的应用和发展,该工艺将会更加注重环保和可持续发展,同时也会不断改进和提高生产效率和质量,该工艺还将会与其他先进技术相结合,提高纺织品的附加值和竞争力。

罗源纺织品干定型工艺是我国纺织工业的重要组成部分,其工艺流程和关键步骤已经得到了广泛的应用和认可,该工艺注重对纤维的均匀处理和定型效果的控制,同时注重环保和可持续发展,随着科技的不断进步和人们对纺织品品质要求的提高,罗源纺织品干定型工艺将会得到更广泛的应用和发展。

Articles related to the knowledge points of this article:

The Fabric of Life:Unveiling the World of Embroidery

A Comprehensive Guide to Purchasing Inventory Textiles in Zhejiang

Empowering Threads:Join Our Team at Yi Pin Textiles

The Art of Textile Dyeing A Comprehensive Guide

Embracing Innovation in Textiles:The Story of Jinde Noble Textiles