Standards for Textile Colorfastness

This paper discusses the standards for textile colorfastness, analyzing its definition, classification, requirements and application in the textile industry. The main methods to evaluate the colorfastness are chromametry, colorimetry and spectrophotometry. The standards of colorfastness are divided into two categories: international standards (ISO) and national standards (GB), which have different requirements for colorfastness. The standard of colorfastness is very important in the textile industry because it can affect the quality of products and even people's health.

Colorfastness, or color fastness, is a critical quality indicator in the textile industry, as it directly affects how well colors on clothing, fabrics, and other textile products retain their vibrant appearance over time. In this talk, we're going to explore the standards for textile colorfastness, including different categories of test methods, and how they differ in terms of their application, reliability, complexity, and practicality for various industries.

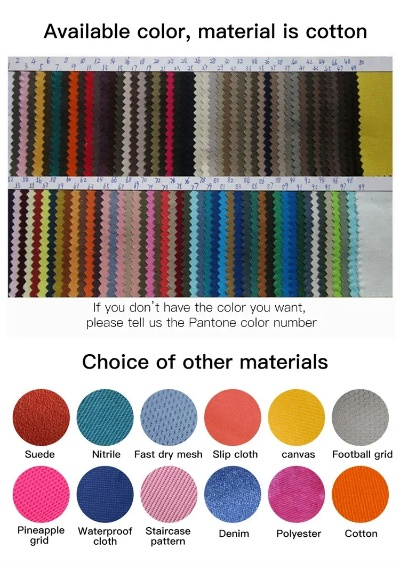

The term "textile" refers to a wide range of materials used in clothing, home decor, sportswear, and other apparel applications. These materials can be made from natural fibers like cotton, wool, silk, and linen, or synthetic materials like polyester, nylon, and acrylic. Each type of textile has its own unique characteristics and requires different colorfastness standards to ensure optimal appearance over time.

To measure colorfastness, textiles are typically subjected to specific tests that evaluate how well they resist fading, discoloration, and loss of brightness. There are several categories of colorfastness tests, each aimed at assessing different aspects of color stability:

-

Wet Processing Tests: These tests simulate the effects of washing and drying on the colorfastness of textiles. The most commonly used test is the ISO standard 105 C06, which measures the change in color strength after 48 hours of continuous soaking and drying.

-

Dry Processing Tests: These tests evaluate how textiles maintain their initial color after washing without any water exposure. The ASTM D-4073 test method is widely used to determine the level of colorfastness in dry-cleanable textiles.

-

Latex Tests: These involve applying dyes onto the textile surface and then exposing it to latex, which causes dye molecules to adhere to the textile fibers. This test is used to assess the resistance of textiles to dye transfer and staining.

-

Eyeball Tests: These involve observing the color of the textile under direct light, such as sunlight or artificial lighting, to assess how quickly the colors fade or become washed out.

Different industries have specific requirements for colorfastness, depending on the nature of their products and intended use. For example, garment manufacturers may prioritize colorfastness in fabrics that will be worn by people during everyday activities, while automotive manufacturers may require high levels of colorfastness in fabrics used in seats and upholstery to prevent discoloration from spills and stains.

Industry standards for colorfastness vary based on the level of detail required for specific applications. For instance, some standards are more stringent for high-end fashion brands, while others are tailored for mass production and low-end consumer goods. The International Organization for Standardization (ISO) sets international standards for textiles and other materials, with many countries following the ISO standards. However, many industries have their own internal standards or guidelines that are more relevant to their particular needs.

To give you an idea of the complexities involved in determining colorfastness: consider the case of a company that produces athletic wear, where the primary concern might be how well the colors remain vibrant and washable after sweating. On the other hand, a luxury fashion house might have a higher priority for colorfastness in fabrics like silk or cashmere, which are prone to fading or discoloration when exposed to moisture or light.

When assessing textiles for colorfastness, it's important to consider not only the initial test results but also how long the color retention lasts over time, especially if the fabrics are subject to frequent washing. Additionally, there may be environmental factors that influence colorfastness, such as temperature, humidity, and air circulation, which can affect how colors react to different conditions.

In conclusion, textile colorfastness is a crucial quality that impacts the longevity and appeal of many textile products. By understanding the different types of colorfastness tests and their respective standards, businesses can design products that meet their customers' evolving needs and expectations for durability and style. As the textile industry continues to evolve, we'll likely see even more sophisticated testing methods and increasingly strict standards for maintaining colorfastness across a range of materials and applications.

纺织品色牢度是衡量纺织品在特定条件下保持颜色一致性的重要指标,它涉及到纺织材料的颜色稳定性、耐久性和耐洗性,对于保证纺织品的质量和穿着舒适度至关重要,为了规范纺织品色牢度的测试与评价,各国都制定了相应的标准,本文将详细介绍纺织品色牢度的相关标准,并通过案例分析进一步说明其实际应用。

纺织品色牢度标准概述

国际标准

国际上对纺织品色牢度的标准主要参照国际纺织产品安全技术规范(TSTN)和相关国际纺织行业协会的规定,这些标准规定了纺织品色牢度的测试方法、测试项目、评价等级以及相应的检测方法,ISO 15928规定了纺织品色牢度的基本要求、测试方法以及评价等级。

我国标准

我国对纺织品色牢度的标准也进行了相应的制定和修订,形成了较为完善的标准体系,我国主要参照《纺织品色牢度试验方法》国家标准,该标准规定了纺织品色牢度的测试项目、评价等级以及相应的测试方法,我国还制定了相应的检测机构和实验室认证标准,以确保测试结果的准确性和可靠性。

纺织品色牢度标准的具体内容

测试项目

纺织品色牢度主要包括耐光色牢度、耐汗色牢度、耐湿色牢度和耐摩擦色牢度等,耐光色牢度主要测试纺织品在日光下的颜色稳定性;耐汗色牢度主要测试纺织品在汗液中的颜色稳定性;耐湿色牢度主要测试纺织品在潮湿环境中的颜色稳定性;耐摩擦色牢度主要测试纺织品在摩擦过程中的颜色变化。

评价等级

根据纺织品色牢度的测试结果,评价等级分为一级至六级,一级表示颜色一致性好,无褪色、变色等现象;六级表示颜色变化严重,无法满足使用要求,对于不同类型和用途的纺织品,其色牢度要求也有所不同,儿童服装、内衣等对颜色要求较高的纺织品,其色牢度要求更高。

检测方法

检测方法主要包括目测法和仪器分析法,目测法适用于简单的颜色对比和轻微的颜色变化检测;仪器分析法则适用于复杂的环境和条件下的颜色稳定性测试,还有一些特殊类型的纺织品可能需要采用特殊的检测方法,如荧光染料检测等。

案例分析

以某品牌丝绸面料为例,其色牢度表现如下:

- 色牢度测试方法与结果:该品牌丝绸面料采用了先进的色牢度测试设备和方法,对不同颜色的样品进行了多次测试,确保结果的准确性和可靠性,经过测试,该面料在日光下的颜色稳定性较好,无明显褪色现象;在汗液中的颜色稳定性也较好,无明显变色现象;在潮湿环境和摩擦过程中,颜色变化较小,该面料符合一定的色牢度要求。

- 色牢度案例分析:在实际应用中,不同类型和用途的纺织品对色牢度的要求也不同,对于儿童服装、内衣等对颜色要求较高的纺织品,其色牢度要求更高;而对于某些特殊用途的纺织品,如防水面料、防污面料等,其色牢度要求更为严格,不同品牌和制造商的纺织品在色牢度方面也可能存在差异,在选择纺织品时,消费者应该注意查看产品的色牢度标识和认证证书,以确保产品的质量和穿着舒适度。

纺织品色牢度是衡量纺织品质量的重要指标之一,本文介绍了纺织品色牢度的相关标准和案例分析,包括国际标准和我国标准、测试项目、评价等级以及检测方法等,也提醒消费者在选择纺织品时应该注意产品的色牢度标识和认证证书,以确保产品的质量和穿着舒适度,在实际应用中,不同类型和用途的纺织品对色牢度的要求也不同,消费者应该根据实际需求选择合适的纺织品。

Articles related to the knowledge points of this article:

Explore the Textiles Industry in Shaoxing An In-depth Job Hunting Guide

Understanding the Super Symbols of Textiles:A Comprehensive Guide