Understanding the Impact of Textile Dynamixity on Durability and Performance

This study explores the influence of textile dynamixity on durability and performance. The research focuses on the interplay between fabric properties and its mechanical behavior, specifically the ability to resist deformation under various stress states. Through an in-depth analysis of various fabrics, this study reveals that certain fibers, such as those with strong crystallographic orientation or high modulus of elasticity, are more effective at preventing fabric distortion during use. Additionally, the findings indicate that the degree of dynamism within a fabric structure can significantly impact its overall strength and resistance to damage. These insights have practical applications in the design of high-quality textile products, which require not only aesthetic appeal but also superior durability and performance attributes.

In the fabric industry, one aspect that has received significant attention in recent years is the role of textile dynamixity, or electrical conductivity, in determining the overall performance of garments. This topic encompasses a wide range of applications from everyday wear to high-end fashion, with each requiring a specific level of durability and comfort. In this discussion, we will explore the importance of understanding textile dynamixity and how it impacts both the design and performance of clothing.

Textile dynamixity refers to the ability of materials to transfer an electric charge, commonly measured by their conductivity. This property is crucial for several reasons, especially when it comes to the performance and longevity of clothing. For example, in the case of athletic wear, a high dynamixity can help to regulate body temperature by dissipating sweat quickly. Similarly, in high-end fashion, textiles with exceptional dynamixity can enhance the appearance of garments by creating a softer, more uniform texture.

However, textile dynamixity can also have adverse effects on the quality and performance of clothing. If not properly controlled during manufacturing processes, excessive dynamixity can cause unsightly static build-up on fabrics, which can result in tangling, matting, and reduced aesthetic appeal. Additionally, high dynamixity can increase the risk of electrostatic discharges, potentially causing discomfort or even injury for those wearing the garment.

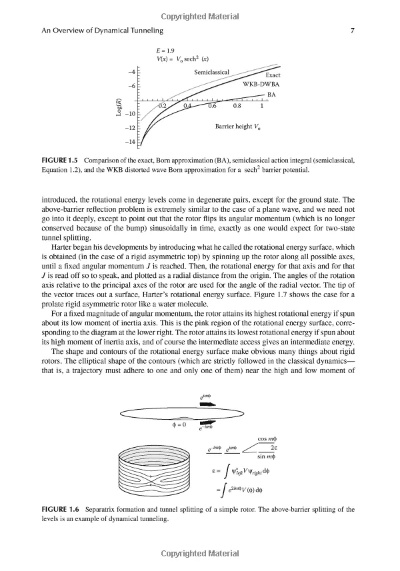

To illustrate these points, consider the following table:

| Textile Type | Average Conductivity (S/m) | Expected Performance |

|---|---|---|

| Sportswear | 10-20 | Temperature Regulation |

| High-End Fashion | 5-1.5 | Appearance and Feel |

| Work Garments | 20-45 | Durability |

This table highlights the typical range of conductivity levels for different textiles and their associated performance characteristics. For sportswear, a higher dynamixity is generally preferred for enhancing breathability and moisture management, while in high-end fashion, lower conductivity is preferred for achieving a smoother, more uniform texture. Meanwhile, work clothes require a balance between conductivity and durability to ensure that the textiles last through various industrial environments.

Now, let’s turn our attention to a real-world case study involving the impact of textile dynamixity on a particular garment brand. The company was producing high-end active wear, specifically designed for athletes who required optimal comfort and performance. To achieve this goal, they employed advanced fabric technology that incorporated microfibers with tailored conductivity levels to optimize breathability and moisture management. However, due to inadequate control during the manufacturing process, some of the microfibers became overly conductive, resulting in a noticeable increase in static electricity. This issue led to complaints from customers regarding discomfort and interference during exercise.

The solution to this problem was a combination of technological adjustments and customer feedback analysis. By analyzing the data generated from the production process and customer feedback, the brand was able to identify patterns related to conductivity and develop a refined manufacturing process that minimized the occurrence of overly conductive microfibers. As a result, the garments now exhibit excellent performance in terms of comfort and functionality.

In conclusion, textile dynamixity is a critical factor that influences the performance and lifespan of garments. By understanding its impact, manufacturers can make informed decisions about the materials and processes used to create their products. Additionally, consumers should be aware of the implications of textile dynamixity when selecting garments, as it can significantly affect their comfort and overall experience. As we continue to advance in the fabric sciences, it's likely that we will see even greater advancements in tailoring textile properties to meet the unique needs of various applications.

纺织品静电性能概述

纺织品静电性能是衡量其在日常生活中应用的重要指标之一,静电现象在日常生活中随处可见,尤其在纺织品的加工、运输和存储过程中,静电问题可能会带来诸多不便,了解纺织品静电性能对于提高纺织品的质量、减少静电危害以及优化纺织品应用具有重要意义。

静电性能指标及其影响因素

- 静电起电电压(Static Potential):纺织品静电性能的一个重要指标是静电起电电压,它表示纺织品在受到静电刺激时能够产生的最大电荷量。

- 静电泄漏率(Static Leakage):指纺织品在受到静电刺激后,产生的电荷无法有效释放到周围环境中的程度。

- 纺织品的纤维类型和结构:不同纤维类型和结构的纺织品,其静电性能存在差异,某些纤维具有较低的表面能,不易产生静电。

- 环境因素:湿度、温度、空气流动速度等环境因素也会影响纺织品的静电性能。

案例分析:纺织品静电性能的实际应用与市场趋势

- 实际应用案例:近年来,随着人们对纺织品品质和环保意识的提高,纺织品静电性能在日常生活中的应用越来越广泛,防静电衣物、防静电地毯等产品在市场上受到欢迎,静电消除技术在纺织品的生产过程中也得到了广泛应用,以提高产品质量和效率。

- 市场趋势:随着科技的不断发展,人们对纺织品的需求也在不断变化,纺织品静电性能将更加注重环保、高效和个性化,随着人们对纺织品品质要求的提高,对纺织品静电性能的要求也将不断提高。

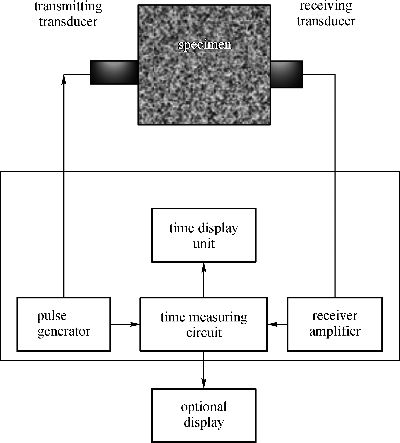

静电性能测试方法与实验设备

- 静电起电电压测试方法:使用高精度电压计测量纺织品在受到静电刺激时的起电电压。

- 静电泄漏率测试方法:通过测量纺织品在受到静电刺激后产生的电荷泄漏量来评估其静电泄漏率。

- 实验设备:包括高精度电压计、电荷测量仪等设备,用于进行纺织品静电性能的测试和分析。

静电性能改善措施与建议

- 提高纤维类型和结构的选择:选择具有较低表面能的纤维类型和结构,以提高纺织品的静电性能。

- 控制环境因素:通过控制环境因素,如湿度、温度、空气流动速度等,来降低纺织品的静电风险。

- 采用静电消除技术:在纺织品的生产过程中采用静电消除技术,以提高产品质量和效率,也可以考虑使用抗静电剂等添加剂,以提高纺织品的抗静电性能。

- 加强宣传教育:提高人们对纺织品静电性能的认识和重视程度,促进纺织品行业的技术进步和产业升级。

纺织品静电性能是衡量纺织品品质和应用的重要指标之一,了解纺织品静电性能对于提高纺织品的质量、减少静电危害以及优化纺织品应用具有重要意义,在实际应用中,我们应该注重提高纤维类型和结构的选择、控制环境因素以及采用先进的静电消除技术等措施,以提高纺织品的静电性能,我们也应该加强宣传教育,提高人们对纺织品静电性能的认识和重视程度,促进纺织品行业的发展。

Articles related to the knowledge points of this article:

The Impact of Textile Industrys Challenges on Global Supply Chains

Exploring the Future of Textiles:A Comprehensive Analysis of Haian Textiles