纺织品检测规模

The Summary:,This paper presents an overview of the textile testing scale, covering various aspects such as sample size, test methods, testing equipment, and data analysis. It emphasizes the importance of standardization in textile testing to ensure consistency and accuracy in results. The paper also discusses the challenges faced by the industry in implementing new testing methods and technologies to meet changing demands for quality and safety standards. Finally, it provides recommendations on how to improve the testing scale and efficiency while maintaining high standards of quality and safety.: Expanding Horizons: The Impact of Technological Innovations in Textile Product Quality Inspection

In the realm of textile manufacturing, quality is the lifeblood that fuels success. With every passing year, technology advances have not just transformed the way we produce and consume textiles but also redefined the parameters of what constitutes a high-quality product. Today, let's delve into the realm of textile quality testing, exploring how innovations are driving an evolution in this crucial sector.

At its core, the textile industry is driven by three pillars: raw materials, manufacturing processes, and quality inspection. In the last few years, there has been a paradigm shift in these pillars, with the introduction of advanced technologies like machine learning, artificial intelligence (AI), and 3D scanning. These innovations have not only improved the efficiency of quality inspection but have opened up new possibilities for tailoring the fabric's properties to meet specific market demands.

Let's take AI as a case study. Machine Learning algorithms can analyze vast amounts of data generated during the production process, identifying patterns and predicting potential issues before they become visible. For instance, AI-powered software can analyze the colorfastness of a fabric by comparing it against a database of past samples. By doing so, manufacturers can ensure that the color does not fade or stain easily, thus improving product reliability.

Another significant advancement is the integration of robotic technology into the textile quality inspection process. Robotic machines are equipped with sensors that can precisely measure the texture, thickness, and density of fabrics. They can work tirelessly 24/7 without fatigue, thereby increasing the speed and accuracy of quality checks. This automation reduces errors, enhances consistency, and ultimately leads to cost savings.

The rise of 3D scanning technology has revolutionized the textile quality inspection process even further. Instead of relying on visual assessments, 3D scanners provide digital models of fabrics that can be analyzed from all angles. This means that defects such as holes or irregularities can be detected more accurately than ever before. Moreover, 3D scanning enables manufacturers to create virtual models of finished products, which can be inspected before they hit the market for any flaws.

As we move forward in this technologically enhanced era, the importance of standardization cannot be overstressed. Standardized testing protocols ensure that each batch of fabric undergoes the same rigorous checks, providing consistent results across different production cycles. This consistency ensures that customers receive consistently high-quality products, boosting brand loyalty and trust in the manufacturer.

Furthermore, as we look towards the future, the integration of blockchain technology could revolutionize the textile quality inspection process. Blockchain-enabled traceability systems enable producers to track their products' journey from raw material to finished product, offering transparency to both consumers and regulatory authorities. This added layer of accountability can help mitigate counterfeiting and ensure compliance with international standards.

In conclusion, the textile industry's quest for excellence is underpinned by technological innovations that have expanded our capabilities beyond what we thought possible just a few years ago. From the integration of AI and robotics to the use of 3D scanning and blockchain technology, the textile quality inspection landscape is constantly evolving, paving the way for increased precision, efficiency, and consumer confidence. As we look ahead, it's clear that the future belongs to those who embrace change and seize opportunities presented by technological advancements.

随着纺织行业的快速发展,纺织品的质量和检测标准变得越来越重要,为了确保纺织品的质量和性能符合市场需求,纺织品的检测规模不断扩大,本文将围绕纺织品检测规模展开讨论,并通过英文案例说明来进一步阐述。

纺织品检测规模概述

检测规模的定义

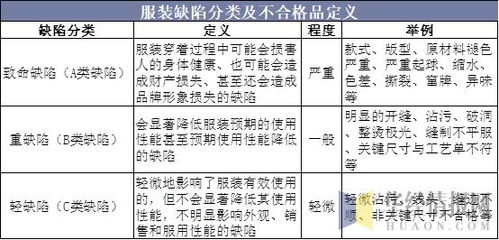

纺织品检测规模是指对纺织品进行全面、系统、科学检测的规模和能力,它涉及到检测设备的种类、数量、质量以及检测流程的复杂程度等多个方面。

国内外纺织品检测现状

纺织品检测规模不断扩大,涵盖了各种材质、纤维、纱线等,随着科技的不断进步,纺织品检测技术也日益成熟,检测精度和效率不断提高,而在国际市场上,各国对纺织品的质量和安全要求也越来越高,因此纺织品检测规模也在不断扩大。

案例分析

以某知名纺织企业为例,其纺织品检测规模的具体情况如下:

设备种类与数量

该企业拥有先进的检测设备,包括各种类型的织机、染化设备、测试仪器等,该企业还建立了完善的检测流程,确保每一种材质、纤维、纱线都能得到全面、系统的检测,该企业还不断引进新技术、新设备,提高检测精度和效率。

检测流程与效果

该企业的检测流程包括样品接收、样品预处理、样品测试等多个环节,通过采用先进的检测技术,该企业的纺织品检测结果准确率非常高,能够满足国内外市场的质量要求,该企业的检测规模不断扩大,为企业的持续发展提供了有力保障。

纺织品检测规模的扩大原因

市场需求的增加

随着人们对于纺织品质量的要求不断提高,市场对于纺织品的需求也越来越大,为了满足市场需求,纺织品的检测规模不断扩大。

技术进步的推动

随着科技的不断进步,纺织品检测技术也日益成熟,先进的检测设备和技术为纺织品检测规模的扩大提供了有力支持,这也为纺织品的研发和改进提供了更多的可能性。

纺织品检测规模是衡量纺织行业发展的重要指标之一,随着科技的不断进步和人们对于纺织品质量要求的不断提高,纺织品检测规模将继续扩大,企业也需要不断引进新技术、新设备,提高检测精度和效率,为企业的持续发展提供有力保障,政府也需要加强对纺织品的监管和管理,确保纺织品的质量和安全符合市场需求。

Articles related to the knowledge points of this article:

A Comprehensive Guide to the Spectroscopic Database for Textiles

The Rich Tapestry of Korean Textiles

A Profile of PJSH Textiles The Fabric of Modern Elegance

Exploring the Global Market with Wuxi Fengyi Textiles

Job Opportunities at Jieyang Textile Factory A Global Talent Landing Pad

The Global Trends and Influence of British Textile Sales in India