High-Quality Textile Production in Gao County,China

Gao County, located in the southern part of China's Guangxi Zhuang Autonomous Region, has been recognized as a leading producer of high-quality textile products. The county boasts a unique geographical location that combines fertile land with favorable climate conditions, making it an ideal location for the growth of textile industries. The local government has implemented a range of policies and incentives to support the development of the textile industry, including tax breaks, investment in infrastructure, and training programs for skilled workers. As a result, the textile sector has experienced rapid growth, with a significant increase in output and job creation. The production techniques employed by manufacturers in Gao County are advanced and efficient, utilizing state-of-the-art machinery and technologies to produce high-quality textiles that meet international standards. The success of the textile industry in Gao County is due to its commitment to innovation, sustainability, and quality control, ensuring that the county's textile products are competitive in the global market.

Introduction: Gao County, located in the northeastern part of Hebei Province in China, is renowned for its high-quality textile production. With a long history of textile industry, Gao County has established itself as one of the leading manufacturers of various types of textile products in Northeast China. In this article, we will explore the textile production in Gao County, detailing the production processes, quality control, and market success of the area's textile industry.

Textile Production Processes: The textile production process in Gao County involves several stages, including raw material sourcing, processing, dyeing, printing, finishing, and packaging. The local producers primarily utilize cotton, silk, linen, and other natural fibers to produce textile products such as shirts, dresses, trousers, and even carpets. Here are some typical steps in the textile production process:

-

Raw Material Collection: The primary raw materials used in textile production are cotton, silk, linen, and synthetic materials. These are sourced from various regions within China, with Gao County's producers being particularly focused on sourcing high-quality cotton from the surrounding areas.

-

Preparation: The collected raw materials undergo various preparation processes to ensure consistency and uniformity in the final product. This includes sorting, washing, drying, and cleaning the fabrics.

-

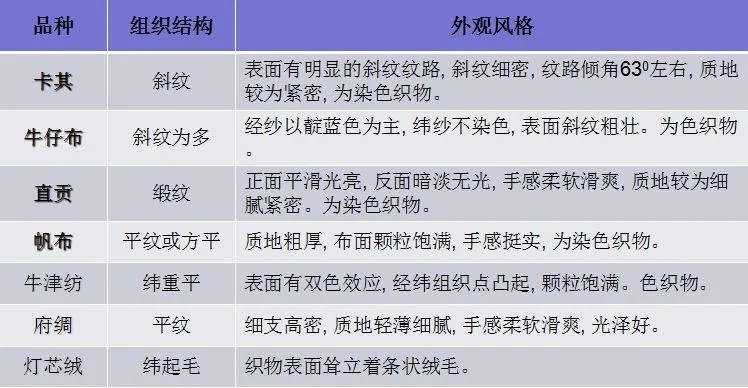

Weaving and Dyeing: Once the fabrics are prepared, they are then woven into different patterns and dyed according to the desired color. The dyeing process involves mixing dyes with water, applying them to the fabrics, and then washing off excess dye.

-

Printing and Patterning: After the fabrics have been dyed, they are printed or patterned according to the specific needs of the garment. This can involve screen printing or embroidery techniques.

-

Finishing: Finally, the textile products are finished to enhance their appearance and durability. This may include adding buttons, zippers, or linings, and ensuring that the seams are properly stitched and sealed.

Quality Control: In order to maintain the high standards of quality that define Gao County's textile production, stringent quality control measures are implemented at every stage of the production process. Here are some key points:

-

Inspection Checklist: A comprehensive checklist is used to ensure that each stage of the production process is completed correctly. This includes checking the color accuracy, pattern alignment, and overall quality of the finished products.

-

Quality Assurance Team: A dedicated quality assurance team is assigned to oversee the entire production process, ensuring that all products meet the required standards. This team is responsible for monitoring quality throughout the entire manufacturing process, identifying any issues early on and resolving them promptly.

-

Inspection Facilities: Advanced inspection facilities and equipment are utilized to ensure consistent and reliable results during the manufacturing process. These facilities allow for precise measurements and evaluations of the fabrics and products, helping to identify any defects or issues before they become noticeable.

Market Success: With a focus on quality and innovation, Gao County's textile industry has gained significant recognition and success in the global market. Here are some examples of how Gao County's textile products have performed:

-

Brand Expansion: Many of Gao County's textile enterprises have successfully expanded into international markets by establishing partnerships with foreign buyers or establishing their own distribution channels. This expansion has led to a significant increase in export sales and an enhanced reputation for the region's textile products.

-

Innovation in Designs: Gao County's textile companies are constantly innovating and introducing new designs and styles to meet the changing demands of the fashion industry. They often collaborate with renowned designers and brands to bring unique and stylish textile products to the market.

-

Sustainable Practices: In recent years, Gao County's textile industry has also made efforts towards environmental sustainability. By adopting sustainable practices such as using eco-friendly dyes and energy-efficient production methods, these enterprises have earned the trust of consumers and increased their market share.

In conclusion, Gao County's textile industry is not only known for its high-quality products but also for its dedication to innovation and sustainability. With a strong focus on quality control and innovative design, Gao County's textile industry has established itself as a leader in Northeast China and beyond.

背景介绍

高阳县作为我国著名的纺织品产地,以其丰富的资源、独特的工艺和良好的产业环境吸引了众多国内外客商,这里汇聚了众多纺织企业,生产出种类繁多、质量上乘的纺织品,为当地经济发展做出了重要贡献。

高阳县纺织品产地概述

地理位置与气候条件

高阳县位于华北平原,地理位置优越,交通便利,这里气候温和,四季分明,为纺织品的生长提供了得天独厚的条件。

产业构成

高阳县的纺织品产业主要包括丝绸、棉布、麻织品等,丝绸产业是当地特色产业之一,以其细腻、柔软、光泽度高等特点闻名,棉布产业则涵盖了各种质地和颜色的纺织品,满足不同消费者的需求,麻织品产业则主要利用当地丰富的麻资源,生产出环保、舒适的家居用品。

高阳县纺织品产地特色案例分析

丝绸产业

高阳县的丝绸产业历史悠久,拥有丰富的丝绸资源,近年来,许多丝绸企业开始采用先进的生产工艺和技术,提高丝绸产品的质量和产量,某丝绸企业通过引进先进的生产设备和技术,提高了生产效率和质量,成为了当地丝绸产业的佼佼者,该企业还注重环保和可持续发展,生产出符合现代消费者需求的产品。

棉布产业

高阳县的棉布产业以高质量、多样化的产品著称,许多棉布企业注重产品的研发和创新,推出了一系列具有地方特色的纺织品,某棉布企业注重产品的功能性,开发出具有吸湿、透气等功能的纺织品,受到了消费者的青睐,该企业还注重产品的环保性,采用环保材料和生产工艺,生产出绿色、健康的纺织品。

高阳县纺织品产地发展策略与建议

加强产业政策支持

政府应加强对高阳县纺织品产业的支持力度,出台相关政策措施,鼓励企业加大技术创新和研发力度,提高产品质量和竞争力,政府还应加强市场监管和公共服务,为企业提供良好的发展环境。

推动产业升级和转型

高阳县应积极推动产业升级和转型,提高纺织品的附加值和竞争力,企业应注重产品的研发和创新,提高产品的科技含量和品质水平,企业还应注重产品的绿色、环保性,生产出符合现代消费者需求的产品。

加强品牌建设和营销推广

高阳县应加强品牌建设和营销推广,提高纺织品的知名度和美誉度,企业应注重品牌形象的塑造和宣传,提高产品的附加值和市场占有率,企业还应加强与国内外市场的联系和合作,拓展市场渠道和销售网络。

高阳县作为我国著名的纺织品产地,其纺织品产业具有广阔的发展前景,在未来的发展中,高阳县应加强产业政策支持、推动产业升级和转型、加强品牌建设和营销推广等方面的工作,不断提高纺织品的品质和竞争力,为当地经济发展做出更大的贡献。

Articles related to the knowledge points of this article:

Textile Factory Emergency Response Card

The Story of Double Connect Textiles:A Multinational Textile Company