Navigating the World of Shipbuilding with Textiles

The integration of textiles into shipbuilding represents a pivotal development, offering unprecedented advantages for both marine infrastructure and the overall performance of naval vessels. This innovative approach leverages the inherent properties of textile materials—such as their high strength, durability, and lightweight characteristics—to enhance structural integrity and reduce operational maintenance costs. By incorporating textile-based components into ship design, builders can create vessels that are more efficient and responsive, capable of withstanding extreme conditions and demanding environments.,The application of textiles in shipbuilding not only enhances the functionality and resilience of the vessels themselves but also plays a crucial role in the sustainable development of the industry. The use of eco-friendly and recycled materials in the construction process reduces waste and promotes environmental stewardship, aligning with global initiatives towards sustainability and green manufacturing.,Moreover, the adoption of advanced fabrication techniques and innovative design strategies enables builders to optimize space and weight distribution within the vessel, further enhancing its efficiency and reducing energy consumption during operation. As the global shipping sector continues to evolve, the integration of textile technologies will undoubtedly play a significant role in propelling advancements in this critical industry.

In the vast world of shipbuilding, textiles play a vital role in creating both structural and decorative elements for ships. The fabrication of these materials is not just a matter of aesthetics but also ensures safety, durability, and functionality. Let's delve into the myriad of textiles used on ships and how they contribute to their overall performance.

Materials Used in Shipbuilding: Textiles

-

Sails: These are the sails that propel a ship forward by harnessing the wind. They come in various shapes and sizes, each designed to optimize speed and efficiency. A well-crafted sail is essential to maintaining directional stability and reducing drag.

-

Ropes: Strong and durable ropes are crucial to securing the ship, guiding its course, and handling cargo efficiently. They are made of materials like hemp, cotton, or synthetic fibers.

-

Canvas: This is a versatile material that can be used for everything from sails to deck coverings. It provides a soft feel to the ship's interior, while also being waterproof, resistant to mold, mildew, and fire.

-

Linen: Linen is a natural fiber that is lightweight, strong, and absorbent, making it ideal for use in clothing, curtains, and other household items. It's also used in ship construction for its resistance to wear and tear and ability to withstand harsh conditions.

-

Silk/Mohair: These are luxurious textiles used in fine furnishings and upholstery on ships. Their soft texture adds a touch of elegance and comfort to the cabin area.

-

Dyeing Materials: To make sails more visible against the blue of the sea, dyed cloths are used. These cloths are treated with dyes and then woven or knitted into the sail's pattern.

-

Tarps and Coverings: Tarpaulins and canvases are used as protective covers to shield the ship's interior from the elements and to protect valuable cargo from damage.

-

Pillows and Upholstery: Comfortable pillows and upholstery fabrics provide a cozy and inviting atmosphere on board.

-

Decking: Heavyweight carpets and rugs serve as a floor covering on decks, providing an additional layer of warmth and comfort.

-

Slinging Materials: Slings and ropes are used to secure ropes and cables during repairs or emergencies. They are often made from high-strength materials like nylon or steel.

Now let us dive deeper into some case studies where textiles have played a significant role in enhancing the performance of ships.

Case Study 1: Sail Design and Durability

In 2017, Royal Dutch Shell launched its new tanker ship, COSMO Excel, which boasts a sleek design and advanced sail technology. The company partnered with a French company, BNP Paribas Technique, to develop a revolutionary sail system. Using carbon fiber materials, the sails are incredibly lightweight yet extremely strong, enabling the ship to sail faster without sacrificing speed or fuel efficiency. This innovative approach showcases how advancements in textile technology can significantly enhance the performance capabilities of large vessels.

Case Study 2: Weather Resistance

The Norwegian oil tanker MS Nord Stream II had to face extreme weather conditions while in transit through the North Sea. To withstand the high winds and waves, the ship was equipped with a state-of-the-art weather protection system using specially treated sails and ropes. These sails were engineered with high-strength fibers and coated with special anti-fouling agents to resist corrosion from saltwater and marine organisms. By implementing this sophisticated system, the ship not only survived but also maintained its speed throughout the journey.

Case Study 3: Interior Decoration

In addition to its functional role, the interior of a ship is equally crucial. A luxurious interior can enhance passenger comfort and provide a sense of luxury and exclusivity onboard. The RMS Titanic, for instance, boasted a beautiful silk carpet that provided a plush and warm feeling to its passengers. Similarly, the QE2, a British cruise liner, used luxurious velvet curtains and silk wallpapers to add a touch of class and sophistication to its cabins. Both these examples underscore how textiles can transform the overall experience of traveling on a ship from merely practical to a luxurious one.

In conclusion, the world of shipbuilding is a fascinating realm where textiles come together to create functional and visually appealing components for vessels. From sails that propel ships forward to cushioned carpets that provide a comfortable ride, textiles play a multifaceted role in enhancing the overall performance of ships. Case studies highlighting the application of textiles in ship designs, weather resistance systems, and interior décor demonstrate how these materials can revolutionize the way we think about ocean travel. As we continue to explore the vast seas, let us appreciate the intricacies of these textile wonders that keep our vessels sailing smoothly and safely through the vast oceanscapes.

船舶上面常见的纺织品种类繁多,涵盖了从装饰性面料到功能性配件的多个领域,以下将通过英文表格和案例说明,详细介绍船舶上面纺织品的种类及其特点。

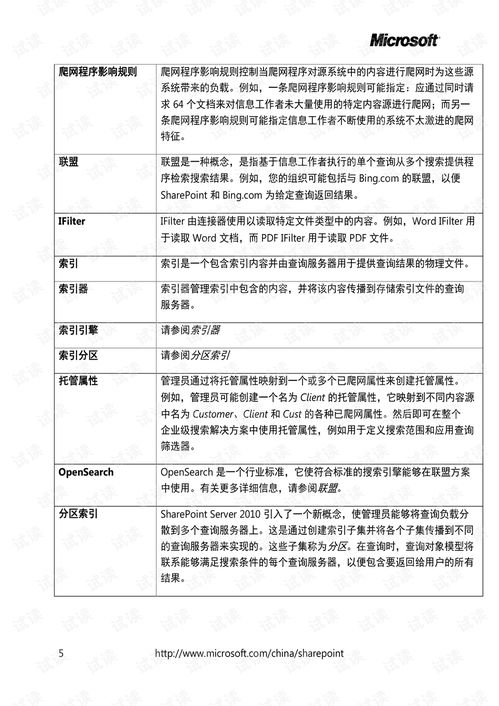

船舶上面纺织品种类

装饰性面料

| 类别 | 描述 | 示例材料 |

|---|---|---|

| 帆布 | 用于船帆、甲板等装饰的帆布面料 | 帆布、尼龙、涤纶等 |

| 亚麻布 | 天然纤维亚麻织物,具有透气、吸湿性好等特点 | 亚麻纤维、棉纤维等 |

| 印花面料 | 采用印花技术制成的纺织品,具有图案美观、色彩丰富等特点 | 棉、涤纶、丝绸等 |

| 织物纹理面料 | 具有独特织物纹理的纺织品,常用于船舱内装饰和美化 | 人造纤维、合成纤维等 |

| 防水面料 | 具有防水功能的纺织品,适用于船舶航行和停靠时使用 | 高分子防水材料、防水涂层等 |

功能性配件

| 类别 | 功能特点 | 示例配件 |

|---|---|---|

| 窗帘 | 用于遮阳、通风和保护隐私的窗帘配件 | 布帘、纱帘等 |

| 座椅面料 | 提供舒适坐感的座椅面料,具有抗磨损、抗污等特点 | 涤纶、尼龙等纤维面料 |

| 防水垫 | 具有防水功能的船舱垫,适用于船舶内部清洁和维护 | 高分子防水材料制成的防水垫面 |

| 灯具配件 | 提供照明功能的灯具配件,如灯具罩、灯带等 | LED灯带、金属材料等 |

案例说明

船舶装饰性面料案例

某大型船舶在建造过程中采用了多种装饰性面料,包括帆布、亚麻布等,帆布采用环保材料制成,具有防水、透气等特点,适合在船帆和甲板等部位使用,亚麻布则具有天然纤维的优点,吸湿性好,能够为船员提供舒适的坐感,该船舶还采用了印花面料和织物纹理面料,为船舱内增添了独特的装饰效果。

功能性配件案例

某船舶配备了多种功能性配件,包括防水垫和灯具配件,防水垫采用高分子防水材料制成,具有出色的防水性能,适用于船舶航行和停靠时的清洁和维护,灯具配件则提供了照明功能,如灯具罩和灯带,为船员提供了舒适的照明环境,该船舶还配备了窗帘和座椅面料等配件,以满足不同的使用需求。

英文表格补充说明

以下是英文表格补充说明:

船舶上面纺织品种类英文表格:

| 类别名称 | 材料示例 | 功能特点描述 | 相关案例说明 |

|---|---|---|---|

| 装饰性面料 | 帆布、亚麻布等天然纤维织物 | 具有防水、透气等特点,适用于船帆和甲板等部位。 | 如某大型船舶使用的帆布面料。 |

| 功能性配件 | 高分子防水材料、灯具配件等 | 提供照明功能,适用于船舶内部清洁和维护。 | 如某船舶的防水垫和灯具配件。 |

| 其他类型面料 | 人造纤维、合成纤维等天然纤维织物及其他特殊材料 | 根据具体需求而定,满足不同的使用场景。 | 如某船舶使用的织物纹理面料等。 |

船舶上面纺织品的种类繁多,涵盖了从装饰性面料到功能性配件等多个领域,在船舶建造和运营过程中,选择合适的纺织品能够提高船舶的美观度和舒适度,同时也能满足不同的使用需求,以上内容仅供参考,如需更多信息,建议查阅相关文献或咨询船舶行业专家。

Articles related to the knowledge points of this article:

纺织品欧盟Reach and ASTM Standards:A Comprehensive Guide for Manufacturers

The Complete Guide to Textile Dyeing Methods