The Innovative Approach to Sustainable Textiles at Tianyuan Textile Factory

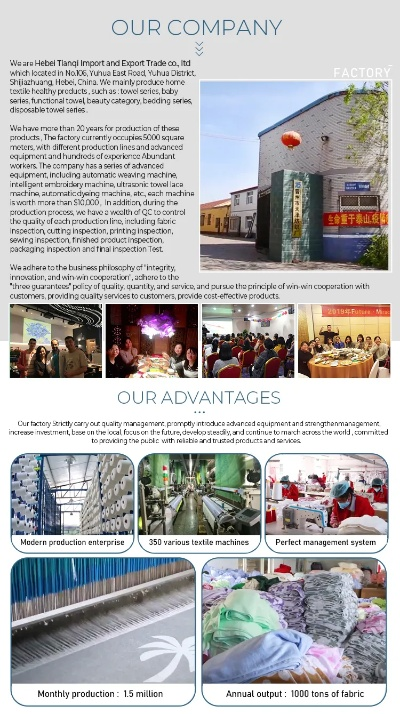

Tianyuan Textile Factory has adopted an innovative approach to sustainable textiles, leveraging cutting-edge technology and a commitment to eco-friendly practices. The company's focus on sustainability is evident in its use of renewable sources such as bamboo and recycled polyester, alongside the implementation of energy-efficient machinery and advanced dyeing processes. By reducing waste and minimizing environmental impact, Tianyuan Textile Factory has established itself as a pioneer in sustainable textile production. This commitment to sustainability not only benefits the planet but also enhances customer satisfaction and reputation among the market.

I. Introduction In today's world, sustainable development has become a global priority, and textile industries are no exception. At Tianyuan Textile Factory, we understand that our responsibility extends beyond just creating products - it's about making the future sustainable for everyone. Our goal is to design, produce, and distribute textiles that are both eco-friendly and fashionable while promoting longevity in our supply chain. In this article, we will explore how we have achieved this balance through our innovative approach to textile production.

II. Our Innovations

-

Use of Eco-Friendly Raw Materials At Tianyuan Textile Factory, we prioritize the use of organic cotton and recycled polyester, which reduces our carbon footprint by up to 30% compared to traditionally sourced materials. By choosing these materials, we not only contribute to environmental conservation but also create a product line that appeals to conscious consumers who value sustainability.

-

Advanced Technology in Textile Production Our factory employs state-of-the-art technology in every step of our textile production process. For instance, our dyeing and printing techniques utilize water-based solvents, reducing pollution and waste generation. Additionally, our cutting-edge equipment allows us to produce high-quality fabrics with minimal energy usage, further advancing our green practices.

-

Efficient Waste Management We have established a comprehensive recycling program at Tianyuan Textile Factory, where all waste materials are processed into new products or turned into compost. This system significantly decreases waste accumulation and minimizes the need for landfill sites. Moreover, our commitment to responsible disposal ensures that our textiles don't harm the environment during their lifecycle.

-

Sustainable Packaging To protect our fabrics during transportation and storage, we use eco-friendly packaging solutions made from natural materials like bamboo or recycled paper. These materials reduce the environmental impact associated with traditional plastic packaging, ensuring that the products reach consumers in a sustainable manner.

-

Collaboration with Renewable Energy Firms To support our commitment to sustainability, Tianyuan Textile Factory has partnered with renewable energy companies to offset our carbon emissions. We have implemented solar panels on our factory roofs and installed wind turbines nearby, generating clean energy that supports our operations and helps lower our carbon footprint.

III. Case Studies

-

Success Story: Green Textiles Market Leadership A recent case study illustrates how Tianyuan Textile Factory's sustainable practices have resonated globally. A leading global fashion brand approached us to develop a collection of sustainable textiles for their upcoming Spring/Summer collections. Through our partnership, we were able to create eco-conscious designs that incorporated recycled materials seamlessly into their signature aesthetic. This collection not only met the brand's sustainability goals but also generated significant demand, solidifying Tianyuan's position as a market leader in sustainable textiles.

-

Challenges Faced and Overcome Despite the progress we have made, Tianyuan Textile Factory has encountered challenges in implementing sustainable practices. One major obstacle was the initial investment required for technological upgrades and new processes. However, our team persevered and worked tirelessly to find cost-effective solutions. Another challenge was consumer awareness around sustainability. To address this, we conducted extensive research and launched educational campaigns to educate our customers about the importance of sustainable textiles and the benefits they offer.

IV. Future Plans

-

Expansion of Sustainability Goals Moving forward, Tianyuan Textile Factory aims to expand its sustainability initiatives further. We plan to implement more stringent measures such as zero-waste manufacturing and increasing our use of renewable energy sources. Our ultimate goal is to achieve complete circular economy principles, where all waste produced from textile production is transformed into new products or resources, thereby closing the loop on our textile production cycle completely.

-

Expanding Global Footprint As we continue to grow, we aim to expand our global presence and bring more sustainable practices to other regions worldwide. This expansion would involve collaborating with partners in different countries to share best practices and implement joint sustainability initiatives. We believe that by working together, we can collectively make significant strides towards a more sustainable future.

V. Closing Remarks At Tianyuan Textile Factory, we understand the significance of sustainability in today's world. By embracing innovative approaches and taking concrete steps to reduce our impact on the environment, we contribute to a brighter tomorrow. Our commitment to sustainable textiles is not just a business strategy; it's a way of life that we hope to inspire others to adopt as well. Thank you for joining us on this journey towards a greener tomorrow.

天圆纺织厂,作为一家专注于纺织行业的现代化企业,以其卓越的产品质量和高效的生产能力赢得了广大客户的信赖和好评,本文将通过英文口语化的方式,为您详细介绍天圆纺织厂的发展历程、生产技术、产品种类以及未来展望。

发展历程

- 创立初期:天圆纺织厂在改革开放初期创立,凭借着对纺织行业的热爱和对技术的执着追求,逐步发展成为一家具有影响力的纺织企业。

- 技术创新:天圆纺织厂不断引进先进的生产技术和设备,提高生产效率和质量,注重技术创新和研发,不断推出新产品,满足市场需求。

- 规模扩大:随着业务的不断拓展,天圆纺织厂不断扩大生产规模,提高生产能力,已经形成了完善的生产链和销售网络,成为当地知名的纺织企业。

生产技术

- 设备介绍:天圆纺织厂主要采用先进的纺织机械和自动化生产线,包括高速织布机、染整设备等,这些设备不仅提高了生产效率,还保证了产品质量。

- 工艺流程:天圆纺织厂的生产工艺流程严格遵循国家标准和行业标准,确保产品质量和安全,注重环保和节能,采用环保材料和节能设备,降低生产成本和能源消耗。

产品种类

- 纺织品种类:天圆纺织厂主要生产各种类型的纺织品,包括棉布、丝绸、麻布等,这些纺织品具有优良的质地和手感,深受消费者喜爱。

- 特色产品:天圆纺织厂还注重开发具有地方特色的纺织品,如手工艺品、家居装饰品等,这些特色产品不仅具有独特的设计风格,还具有很高的收藏价值和投资价值。

案例说明

以天圆纺织厂为例,介绍其在纺织行业中的成功案例。

- 成功案例一:新产品研发与市场推广 近年来,天圆纺织厂不断进行新产品研发和推广,他们成功推出了一系列具有时尚感和环保意识的纺织品,受到了消费者的热烈欢迎,他们还通过线上线下相结合的方式,扩大产品销售范围和市场份额。

- 成功案例二:绿色生产与环保理念 天圆纺织厂注重绿色生产和环保理念,采用环保材料和节能设备进行生产,他们积极推广环保知识和理念,提高员工环保意识,为当地环境保护做出了积极贡献。

展望未来,天圆纺织厂将继续秉承创新、高效、环保的理念,不断提高生产能力和产品质量,满足市场需求,他们还将继续拓展业务范围和销售网络,提高品牌知名度和影响力。

天圆纺织厂作为一家专注于纺织行业的现代化企业,凭借着卓越的产品质量和高效的生产能力赢得了广大客户的信赖和好评,在未来发展中,他们将继续努力提高生产能力和产品质量,为当地经济发展做出积极贡献。

Articles related to the knowledge points of this article:

The Beauty of a Textile Factory Girls Hair

The Transformation of Yangquan Mu County Textile Factory