The Textiles Appearance Inspection Checklist

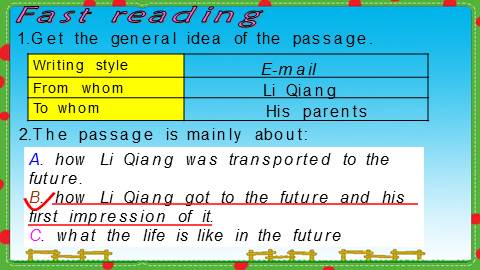

"The Textiles Appearance Inspection Checklist" is a comprehensive document that outlines the key aspects of textiles appearance inspection. This checklist includes items such as fabric texture, color accuracy, pattern alignment, and stitching quality. It also covers issues related to dyestuff uniformity, shrinkage and warp/weft inconsistencies, and thread breaks or frays. Additionally, the list includes specific guidelines for detecting defects such as stains, holes, and tears. The inspection process typically involves visual assessments, measuring tools, and specialized equipment. Overall, this checklist serves as a valuable tool for both textile professionals and retailers who are responsible for ensuring high-quality products.

Introduction In the world of textiles, appearance inspection is crucial for ensuring quality and consumer satisfaction. This checklist aims to help textile manufacturers and inspectors standardize their processes, identify potential issues early on, and maintain consistent levels of product excellence. It covers a wide range of aspects related to visual inspection of fabrics, yarns, and other textile components.

-

General Guidelines Before diving into specific inspection details, it's essential to have a basic understanding of how to conduct general appearance inspections effectively. These include assessing color consistency, thread count, weave pattern, and overall finish.

-

Color Consistency Analyze the color of the fabrics for any discoloration, bleeding, or inconsistencies in hue. Ensure that the colors match the manufacturer's specifications and meet industry standards.

-

Weave Pattern Check for proper weave patterns such as plain weave, twill, satin, plaid, or others. A well-woven fabric should have even stitches without gaps or holes.

-

Thread Count Verify the thread count of the yarn or fabric. High-end textiles often have a thread count listed to indicate the fineness of the yarn, which impacts its strength and durability.

-

Surface Finish Examine the surface texture of the fabrics for any roughness or unevenness. Look for smoothness, uniformity, and absence of pilling or excessive shedding of fibers.

-

Edge Quality Check the edges of textiles for sharpness, straightness, and uniformity. Any noticeable fraying or unevenness can compromise the product's appearance and functionality.

-

Patterning Verify the accuracy of printed patterns or any embellishments on the fabric, checking for proper registration and alignment.

-

Size Verification Measurements are essential in textile products to ensure they fit properly. Check measurements against the label or manufacturer's specifications.

-

Packaging and Display Ensure that the packaging and display of textiles are appropriate for their intended use. Labeling should be clear and legible, and the products should be displayed in a manner that highlights their best features without obscuring them with unnecessary clutter.

-

Sample Preparation and Handling Before conducting actual inspection, prepare samples by washing and drying them to remove any wrinkles or creases that could affect the appearance of the finished product. Store them correctly to prevent damage from moisture or dust.

Case Study: A Failed Appearance Inspection in a Textile Manufacturer’s Supply Chain

One example of an apparent failure in an apparel company was when a supplier failed to meet the appearance inspection requirements for a high-quality knitted garment. Due to inadequate weaving quality, the final garment had visible seams that were more than double the size specified. This led to customer complaints and a significant drop in sales, highlighting the importance of thorough inspections in maintaining product quality and brand reputation.

Conclusion The Textiles Appearance Inspection Checklist serves as a comprehensive guide to help textile manufacturers and inspectors ensure their products meet industry standards while maintaining consumer expectations for quality and beauty. By following this checklist and incorporating it into their routine operations, businesses can minimize the risk of rejects and maximize product success rates.

随着纺织品行业的快速发展,纺织品质量检验越来越受到重视,为了确保纺织品的质量和安全,国家出台了一系列纺织品调出法检目录,为纺织品生产、销售和进出口提供了明确的检验标准和依据,本文将详细解析纺织品调出法检目录的内容,并结合案例说明进行深入探讨。

纺织品调出法检目录概述

纺织品调出法检目录主要包括纺织品的质量标准、检验项目、检验流程等内容,主要包括以下几个方面:

- 纤维含量检测:包括纤维种类、含量等指标的检测。

- 化学成分检测:包括染料、助剂等化学成分的含量和种类。

- 规格尺寸检测:包括纺织品尺寸、规格等指标的检测。

- 安全性能检测:包括环保、安全标志等指标的检测。

检验项目案例分析

以某纺织品生产企业为例,详细解析其调出法检目录中的检验项目案例。

纤维含量检测案例

该企业生产的纺织品主要采用天然纤维,包括棉、麻等,在纤维含量检测方面,主要检测纤维种类、含量是否符合国家标准,该企业采用了先进的纤维分析仪器,对原料进行纤维含量检测,确保纤维种类和含量符合国家标准,该企业还建立了完善的纤维质量追溯体系,确保每批纺织品的质量可控。

化学成分检测案例

该企业生产的纺织品主要使用染料和助剂,为了确保产品质量和安全性,该企业进行了染料和助剂的质量检测,该企业采用了高效液相色谱仪等先进的化学分析仪器,对染料和助剂进行定性、定量分析,确保其符合国家标准和安全性能要求,该企业还建立了完善的化学成分检测流程,确保每批纺织品的质量可控。

检验流程说明

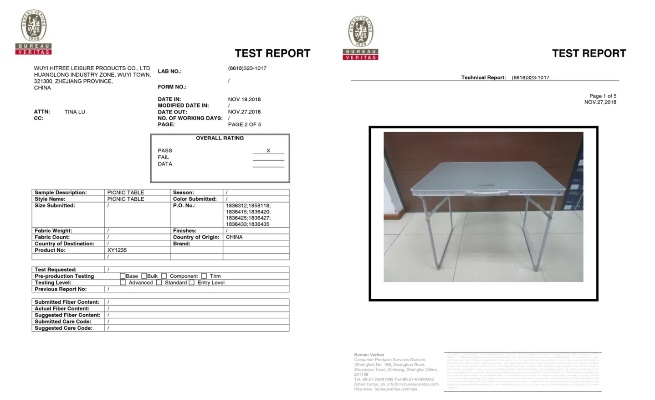

纺织品调出法检流程主要包括以下几个步骤:

- 样品采集:从生产企业或销售企业采集样品。

- 样品预处理:对样品进行清洗、破碎等处理,确保样品符合检验要求。

- 检验检测:使用专业的检验仪器和试剂,对样品进行各项指标的检测。

- 结果报告:根据检测结果,出具检验报告。

纺织品调出法检目录是国家对纺织品质量安全的重要保障措施之一,通过制定纺织品调出法检目录,明确了纺织品的质量标准和检验项目,为纺织品生产、销售和进出口提供了明确的依据,通过案例分析,可以看出检验项目的重要性以及检验流程的规范性,在实际操作中,企业应该严格按照检验目录进行检验,确保纺织品的质量和安全。

Articles related to the knowledge points of this article:

Textile Classification,Components,and Care

List of Textile Pasting Accelerators

The Journey of Hua Jia Textile Research and Development Center