The Art of Textile Testing:A Comprehensive Guide for the Shirt Industry

"The Art of Textile Testing: A Comprehensive Guide for the Shirt Industry" is a book on textile testing that provides detailed instructions for garment manufacturers. It explains the various tests and methods used to ensure the quality of fabrics, yarns, and other textile materials. The author also discusses how to select appropriate testing equipment and how to interpret test results correctly.,This book covers topics such as dyeing and finishing processes, which affect the final color and texture of the shirt, and how to measure the proper dimensions and fit of the fabric. Additionally, it includes information on how to handle and store different types of fabrics, including cotton, polyester, and blended fibers.,Overall, "The Art of Textile Testing" is an essential resource for anyone working in the shirt industry. By following these guidelines, manufacturers can ensure their products meet the highest standards of quality and durability.

I. Introduction to Shirt Quality Control

In the competitive world of fashion, ensuring that shirts meet high standards is crucial to a garment's success. At [Textile Testing Company], we specialize in providing comprehensive and meticulous testing services to guarantee the quality, functionality, and durability of shirts. Our commitment to excellence is reflected in every detail of our process, from selecting the right fabric to conducting rigorous testing methods. In this article, we will delve into the essential steps involved in shirt quality control, including the various textile testing methods we employ and the benefits they offer.

II. Textile Testing Methods

Material Analysis

To ensure the shirt's fabric meets the desired standards, we analyze its composition using advanced analytical techniques like Fourier Transform Infrared Spectroscopy (FTIR) and Differential Scanning Calorimetry (DSC). These tests help us identify any potential issues with the material, whether it's moisture absorption, color stability, or temperature resistance.

Stability Tests

Stability tests evaluate how well the shirt fabric resists changes in temperature, humidity, and light exposure. For example, we conduct accelerated aging tests to assess how quickly the fabric deteriorates under specific conditions. By identifying these factors early, we can prevent defects from developing during production and shipping.

Shrinkage Tests

Shrinkage is one of the most common fabric defects that can significantly affect garment fit and comfort. To ensure that our shirts are free from these issues, we perform shrinkage tests on various fabric samples to measure their initial and post-wash sizes. This information helps us optimize our dyeing and printing processes to achieve optimal results.

Colorfastness Tests

Colorfastness is crucial for shirts as they are often worn in various environments and with different activities. Through colorfastness tests such as Hunter Color Difference and Color Transfer Resistance tests, we ensure that the colors remain vibrant and uniform across the shirt throughout its lifespan.

Weave and Pattern Tests

Weave and pattern tests help us understand the structural integrity of the shirt fabric. These include tests such as Tensile Strength and Elongation tests to ensure that the threads hold together evenly and do not break easily. These tests also help us determine if the patterns align properly and are consistent across the entire garment.

III. Importance of Textile Testing in Shirt Production

Textile testing is an integral part of the shirt production process. It ensures that each piece of clothing meets the required specifications and provides consumers with a high-quality product. By incorporating these testing methods into our process, we can mitigate the risk of defects during production and minimize wastage. Moreover, our expertise in these areas enables us to provide tailored solutions to our clients based on their unique requirements.

IV. Role of Textile Testing in Shirt Quality Assurance

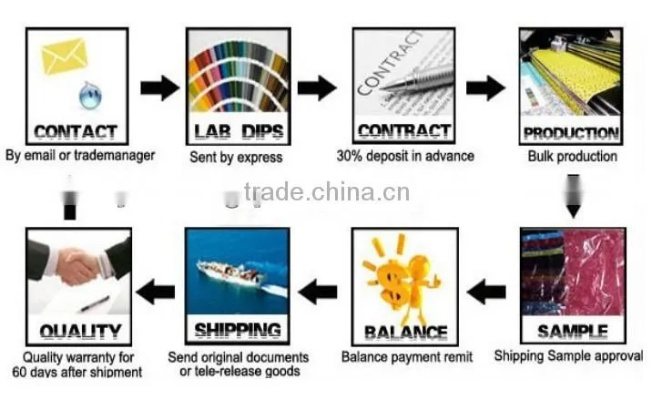

Pre-Order Process

Before placing an order for shirts, we conduct thorough pre-order testing to assess the fabric's quality and potential issues. This step allows us to communicate with customers effectively and address any concerns they may have regarding the product's performance.

Post-Production Review

After receiving shipments, we perform post-production testing on the shirts to ensure that they meet our strict standards. This review helps us identify any defects or errors immediately, allowing us to take corrective action before sending out any more products to our customers.

Customer Satisfaction Tracking

Our commitment to excellence extends beyond product testing; we also prioritize customer satisfaction. We track feedback from customers about their experiences with our shirts, which allows us to improve our service and product offerings continually. By listening closely to our customers and implementing their suggestions, we ensure that their expectations are met and exceeded.

V. Case Study: Successful Shirt Quality Control at [Textile Testing Company]

At [Textile Testing Company], we have seen firsthand the importance of stringent quality control measures in achieving success for our clientele. A prime example of our commitment to excellence is the successful implementation of our textile testing services for a major clothing brand that produces high-quality shirts.

In this particular case, the client faced challenges with certain fabric materials that were prone to shrinkage and discoloration during washing. Our team identified these issues early in the testing stage, allowing us to develop targeted solutions that addressed the problem. We also optimized the dyeing and printing processes to ensure that the colors remained vibrant and uniform across all shirts.

As a result of our collaboration and dedication, the client experienced a significant improvement in the overall quality of their products. The increased durability of the fabric materials allowed for longer shelf life and better fit and comfort for customers. This positive experience led to a steady growth in business and a loyal customer base that continues to trust our company for their shirt quality assurance needs.

VI. Challenges Faced During Shirt Quality Control

Despite our extensive experience and expertise in textile testing, there are still challenges encountered during shirt quality control. One common issue is the variability in fabric properties due to different suppliers and raw materials. Another challenge is ensuring that all components of the shirt—from the fabric to the buttons and zippers—are up to par with industry standards.

To overcome these challenges, [Textile Testing Company] invests in continuous training programs for our staff to stay updated with the latest advancements in textile testing technology. We also work closely with suppliers to ensure that they adhere to high standards of quality and sustainability practices. Additionally, we utilize advanced analytical tools and machine learning algorithms to improve our accuracy and efficiency in detecting defects during production stages.

VII. Embracing Technological Advances for Enhanced Textile Testing Services

In today’s fast-paced fashion industry, technological advancements play a crucial role in enhancing our textile testing services. We leverage state-of-the-art equipment like laser scanners, X-ray machines, and digital image analysis software to detect hidden flaws more accurately than ever before. These technologies enable us to identify issues with complex patterns and intricate stitching without compromising on speed or precision.

Moreover, we integrate artificial intelligence (AI) into our testing process. AI algorithms can learn from historical data and predict potential issues before they occur, helping us to reduce downtime and streamline the testing process. Additionally, AI can automate routine tasks, allowing us to focus on more challenging aspects of textile testing.

By embracing these technological advancements, we are able to provide our clients with cutting-edge textile testing services that meet the highest levels of quality standards. This not only enhances the overall customer experience but also sets us apart from our competitors and secures our place as a leader in the shirt quality control industry.

VIII. Future Trends in Shirt Quality Assurance

As the fashion industry continues to evolve, so too does our approach to shirt quality assurance. One trend we are witnessing is an increasing demand for eco-friendly and sustainable fabrics. With consumers becoming increasingly conscious of environmental impacts, we are adapting our testing protocols to include more stringent guidelines for biodegradable materials and recycled content.

Additionally, we are seeing an increase in demand for personalized and customizable shirts. To cater to this market segment, we are integrating advanced 3D printing technology into our testing process to create accurate models of fabrics and patterns. This enables us to produce highly customized shirts that meet individual customer preferences and specifications.

Furthermore, wearable tech has emerged as a new frontier in apparel design. As such, we are exploring ways to incorporate smart fabrics into our testing process, enabling us to monitor wearer comfort levels, moisture absorption, and other wearability metrics through embedded sensors. This technology will allow us to tailor shirts specifically for active wearers or those seeking enhanced performance in certain sports or industries.

IX. Closing Remarks on Shirt Quality Testing at [Textile Testing Company]

In conclusion, shirt quality assurance is not just a technical process but a reflection of our commitment to excellence and customer satisfaction. By utilizing advanced testing methods and leveraging technological advancements, we are able to provide our clients with high-quality shirts that meet their demands. From pre-order testing to post-production reviews, our comprehensive testing process ensures that each item delivered is flawless and meets our uncompromising standards.

As we embrace the future trends and continue to innovate, [Textile Testing Company] remains at the forefront of shirt quality control. We are excited about the opportunity to collaborate with our clients and partners on their journey towards exceptional apparel designs and experiences. Together, let us strive for excellence in the fashion industry and leave a lasting impact on the lives of our customers through the art of shirt manufacturing.

随着纺织行业的快速发展,衬衫纺织品的质量检测成为了行业关注的焦点,我们将以一家专注于衬衫纺织品检测的公司为主题,分享其检测流程、案例以及相关技术。

本案例涉及的公司是一家专注于衬衫纺织品检测的纺织品检测公司,拥有先进的检测设备和专业的检测团队,该公司致力于为客户提供高质量的纺织品检测服务,确保纺织品符合国际标准和客户需求。

检测流程

样品采集:客户提供样品,包括衬衫面料、里料、辅料等。 2.样品预处理:对样品进行清洗、整理,确保样品符合检测要求。 3.检测设备使用:使用先进的检测设备对样品进行检测,包括纤维含量测定、织物结构分析、化学成分分析等。 4.数据分析与报告:对检测结果进行数据分析,出具检测报告,报告内容包括面料成分、织物结构、耐洗性能等。

案例说明

案例一:某品牌衬衫纺织品检测

某品牌近期收到一批衬衫纺织品订单,需要对其质量进行全面检测,该公司接到订单后,迅速安排专业团队进行样品采集和预处理,在检测过程中,使用先进的纤维含量测定设备对面料纤维含量进行精确测量,同时进行织物结构分析和化学成分分析,确保面料符合客户需求,最终出具了详细的检测报告,为该品牌提供了有效的质量控制依据。

案例二:新技术应用案例

近年来,该公司引入了先进的纺织品检测新技术,如智能传感器技术、大数据分析技术等,这些新技术在检测过程中得到了广泛应用,提高了检测效率和准确性,该公司使用智能传感器技术对纺织品进行实时监测,及时发现并处理潜在的质量问题,该公司还利用大数据分析技术对检测数据进行深入分析,为质量控制提供科学依据。

技术说明

纤维含量测定:纤维含量测定是纺织品检测的重要环节,通过使用先进的纤维含量测定设备,可以精确测量面料纤维含量,确保面料符合国际标准和客户需求。 2.织物结构分析:织物结构分析是通过观察织物的纹理、密度等特征,了解织物的结构和性能,该公司在织物结构分析方面采用了先进的图像处理技术和计算机辅助设计软件,提高了分析的准确性和效率。 3.化学成分分析:化学成分分析是纺织品检测的重要环节之一,通过对面料中的化学成分进行分析,可以了解面料的质量和性能,该公司在化学成分分析方面采用了高效的分析仪器和专业的分析人员,确保了分析结果的准确性和可靠性。

本案例表明,一家专注于衬衫纺织品检测的公司通过先进的检测设备和专业的检测团队,可以为客户提供高质量的纺织品检测服务,该公司引入了先进的检测技术和新设备,提高了检测效率和准确性,该公司还注重质量控制和持续改进,为提高纺织品质量提供了有效的保障。

Articles related to the knowledge points of this article:

Testing Fabric Content for Fibers in Textile Industry

Textile Quality Inspection Checklist Template

Nantong Mingxin Lier Textiles:A Review

The Role of Medical Wearables in Enhancing Healthcare Quality