Transforming Textiles:The Story of the BG Groups Fabrication Plant

:Transforming Textiles: The Story of the BG Group Fabrication Plant,Abstract:,The transformation of textiles from traditional processes to modern, efficient manufacturing techniques has been a significant milestone in the industry. This paper delves into the journey of the BG Group, an influential textile fabrication plant that has revolutionized the sector through innovative technologies and sustainable practices. The BG Group has achieved remarkable progress by adopting state-of-the-art equipment, implementing lean production methodologies, and fostering a culture of continuous improvement. Their commitment to quality and customer satisfaction has positioned them at the forefront of the textile industry, while their dedication to environmental sustainability has set a benchmark for other firms in the sector. Through their pioneering efforts, the BG Group has not only transformed the fabrication process but also reshaped the perception of what it means to be an effective textile manufacturer.

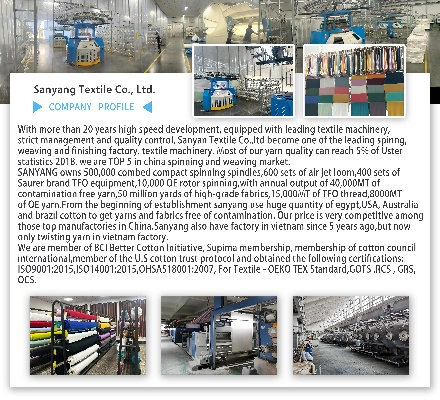

The BG Group, as a leading developer and owner in China, has been making significant strides in the realm of textile manufacturing. This is particularly evident at its latest venture, the BG Group Textile Factory located in Guangdong Province. The factory's operations are centered around producing high-quality textile products for a wide range of industries. In this article, we explore the history, current operations, and future plans of the BG Group Textile Factory.

Historical Background:

The BG Group was founded in 1992 with the goal to become a global leader in the construction materials industry. Over the years, it diversified into various sectors, including manufacturing, real estate, and technology. However, textile production remained an integral part of the group's portfolio, focusing on providing high-quality apparel, home textiles, and other related products.

In 2015, BG Group decided to invest in a new textile factory to expand its textile product lines and meet growing market demands. The factory was designed to be environmentally friendly and sustainable, aligning with global trends towards eco-friendly manufacturing practices.

Current Status:

Today, the BG Group Textile Factory boasts a workforce of over 500 people, employing more than 300 local workers. The factory produces a variety of textile products, including cotton, synthetic fabrics, and blends, catering to a broad range of consumer needs.

One key area where the factory excels is in the use of advanced technologies and machinery. It employs state-of-the-art automated machines that significantly reduce labor costs and increase productivity. Additionally, the factory implements green technologies such as solar panels and wastewater treatment systems to minimize its environmental impact.

Case Studies:

A prime example of the BG Group Textile Factory's success is its partnership with a major international clothing brand. In collaboration with the brand's design team, the factory produced custom-made fabrics that met exacting quality standards for the brand's flagship line. This partnership not only boosted the factory's reputation but also increased sales revenue significantly.

Another notable achievement is the factory's commitment to sustainability. By implementing eco-friendly practices such as reducing water usage and minimizing energy consumption, the factory has earned certifications from international sustainability organizations. This commitment has helped the BG Group Textile Factory secure orders from customers worldwide who prioritize eco-friendly products.

Future Plans:

Looking towards the future, the BG Group Textile Factory plans to expand its product line further, introducing more innovative fabrics and designs. It also aims to strengthen its supply chain management by investing in automation technology to improve efficiency and reduce costs further. Additionally, the factory is exploring opportunities to diversify its business scope, possibly entering the fashion accessories or home decor industry.

In conclusion, the story of the BG Group Textile Factory is one of growth, innovation, and sustainability. With its commitment to producing high-quality textile products and adopting eco-friendly practices, the factory is poised to continue its legacy of transforming textiles for decades to come.

背景介绍

碧桂园纺织厂位于中国广东省的一个工业重镇,以其先进的生产技术和卓越的产品质量而闻名,该厂致力于生产高质量的纺织品,满足国内外市场的需求。

工厂概况

- 地理位置:位于广东省的一个纺织产业园区,交通便利,拥有完善的配套设施。

- 生产设备:采用先进的纺织机械和自动化生产线,确保产品质量和效率。

- 员工队伍:拥有一支高素质的员工队伍,具备丰富的生产经验和专业技能。

产品与服务

- 产品种类:主要生产各类纺织品,包括但不限于床上用品、服装、装饰品等。

- 质量保证:严格遵循国际质量标准,确保产品质量和安全。

- 客户群体:主要面向国内外市场,提供高品质的纺织品产品。

案例分析

以下是碧桂园纺织厂的一些案例说明:

成功案例一:绿色环保纺织品生产

近年来,碧桂园纺织厂积极响应国家绿色环保政策,大力推广绿色纺织品的生产,该厂采用环保材料和技术,生产出的纺织品不仅环保无害,而且具有较高的舒适度和美观度,该厂还注重员工环保意识的培养,鼓励员工参与环保活动,提高企业的社会责任感。

成功案例二:个性化定制纺织品

为了满足消费者对个性化定制的需求,碧桂园纺织厂推出了一系列个性化定制纺织品服务,该厂可以根据消费者的需求和喜好,量身定制纺织品款式、颜色、尺寸等,提供全方位的个性化服务,该服务受到了广大消费者的欢迎和好评。

生产工艺与流程

- 原料采购:从优质原料供应商处采购高质量的原料,确保产品质量和稳定性。

- 纺纱与织造:采用先进的纺纱技术和织造工艺,生产出高质量的纺织品。

- 质量控制:严格遵循国际质量标准,对每道工序进行严格的质量控制,确保产品质量和安全。

- 设备维护与保养:定期对设备进行维护和保养,确保设备的稳定性和效率。

碧桂园纺织厂将继续秉承“质量第一、客户至上”的原则,加强技术创新和人才培养,提高产品质量和竞争力,该厂还将拓展国内外市场,提高品牌知名度和影响力,碧桂园纺织厂将继续致力于发展绿色纺织产业,为推动中国纺织产业的发展做出更大的贡献。

Articles related to the knowledge points of this article:

A Brief Guide to the Fabrication Process at Shang Li Textile Factory

The Art of Threading:Textile Mills纱线加捻工艺

Navigating Challenges in the Textile and Laundry Industry:A Guide to Success