Understanding and Applying Standards for Textile Strength Testing

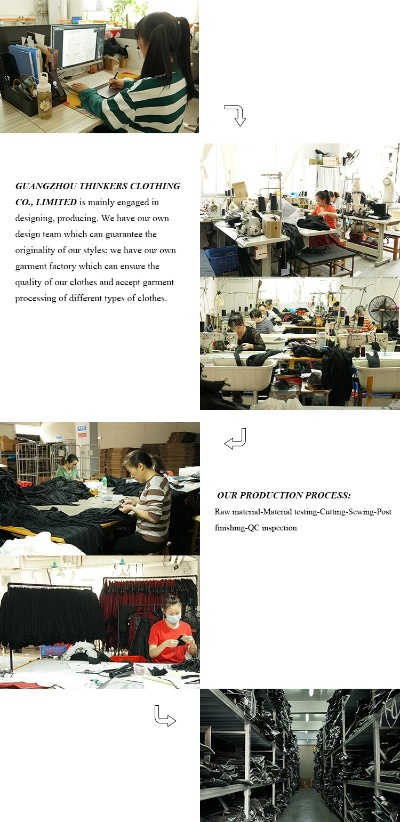

: Understanding and Applying Standards for Textile Strength Testing,Textiles have become an indispensable part of our daily lives, with their strength, durability, and comfort properties making them a preferred choice among various materials. The standard testing methods for textile strength are essential for ensuring the quality and reliability of these products.,Firstly, it is important to understand the purpose of textile strength testing. This type of testing is designed to evaluate how well a textile material resists tearing, puncture, and compression under specific conditions. These tests provide valuable data on the material's resistance to wear and tear, which is crucial for industries such as apparel, sportswear, and automotive seating components.,When conducting textile strength testing, several factors need to be considered, including the type of material, the test method, and the testing equipment used. For instance, the use of high-quality yarns and fabrics can significantly enhance the strength of the resulting textile. Additionally, the application of appropriate test methods, such as using tension, compression, or bending forces, will determine the results obtained from the testing process.,In conclusion, understanding and applying standards for textile strength testing is essential for ensuring the quality and longevity of textile products. By following proper testing procedures and using the right equipment, manufacturers can confidently claim that their textiles meet the necessary performance standards.

Introduction: Textiles, being a crucial part of our daily lives, are subjected to various stresses in their manufacturing process and use. These stresses can range from normal wear and tear to extreme environmental conditions. As such, it's essential that these materials meet stringent standards to ensure they can withstand the demands of everyday life or even more demanding industrial settings. In this article, we will delve into the testing methods for determining textile strength, including the common types of tests used and how they compare. Additionally, we'll present an example of how these standards have been applied in the real world, highlighting both the challenges faced during testing and the benefits of meeting these standards.

Common Methods of Textile Strength Testing:

-

Tensile Testing: Tensile testing is one of the most widely used techniques for assessing the mechanical properties of textile materials. It measures the force required to stretch a fabric sample under a controlled tension. The resultant force-extension curve is analyzed to determine the material's elongation at break, which is often expressed as the percentage elongation (%E) or the breaking strain.

-

Compression Testing: This test involves applying compressive loads to textile samples until they rupture. The resulting load required for rupture provides insight into the material's compression strength, which can be compared to its tensile strength to understand its overall performance.

-

Tearing Test: A tear test measures how easily a fabric can be torn apart when pulled across a surface. This method provides information on the fabric's resistance to tearing, particularly important in applications where durability is a primary concern.

-

Elongation Recovery Test: This test measures how quickly a textile sample regains its original length after being stretched beyond its original length. This property is important for understanding the material's flexibility and recovery capacity.

-

Yield Test: A yield test evaluates the amount of strain a textile sample can withstand before failing. It helps predict how the material will perform under cyclic stresses, making it useful in industries that experience repeated strain.

-

Impact Testing: For textile products intended to withstand impacts, such as protective gear, impact tests are conducted using standardized drop weights and measuring the force needed to rupture the fabric.

Application of Standards in Real World Examples:

Let's consider the case of a sportswear manufacturer that produces high-performance athletic clothing. They are subject to strict standards set by the International Olympic Committee (IOC) and the International Organizing Committee for the Continental Cup (OCC). These standards mandate that their fabrics undergo rigorous testing procedures, including tensile strength testing and elongation recovery testing, to ensure they meet certain specifications. For instance, the IOC requires that sportswear must have a minimum breaking strength of 10 MPa (million pascals) and a maximum elongation recovery of 80% at break, while the OCC sets higher requirements for certain categories.

In another example, a textile company producing outdoor apparel faced a challenge during product development due to a sudden demand surge caused by extreme weather events. To address this issue, the company implemented a comprehensive testing protocol that included not only traditional tensile and compression tests but also impact tests to ensure the fabrics were durable enough to withstand harsh conditions. By doing so, they were able to produce a line of outdoor apparel that met all the necessary standards and was well-received by customers who appreciated the increased quality and reliability of their products.

Conclusion: Textile strength testing plays a critical role in ensuring the safety and performance of textile products. Whether it's for consumer goods or industrial equipment, these tests help manufacturers comply with international standards and provide assurance to consumers that their products meet industry-specific requirements. By understanding the different testing methods and applying them correctly, textile manufacturers can gain valuable insights into improving product quality and performance.

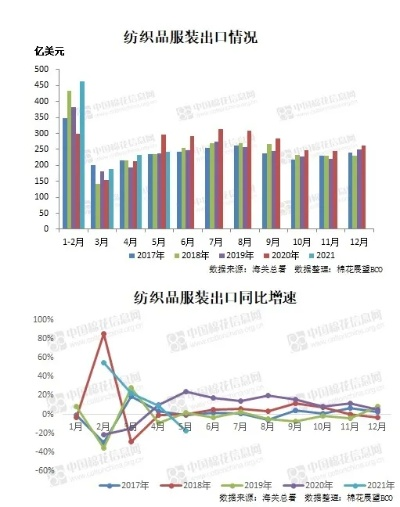

在纺织品生产过程中,抗拉强度是衡量其质量的重要指标之一,为了确保纺织品的质量和性能,对其抗拉强度进行准确检测是至关重要的,本文将详细介绍纺织品抗拉强度检测的方法,并结合实际案例进行分析。

纺织品抗拉强度检测方法

拉伸试验机检测法

拉伸试验机是一种常用的纺织品抗拉强度检测设备,该方法通过设定一定的拉伸力,对纺织品进行拉伸测试,以测量其抗拉强度,具体步骤包括准备样品、设置试验参数、进行拉伸测试等,在测试过程中,需要注意控制温度、湿度等环境因素,以确保测试结果的准确性。

显微镜检测法

显微镜检测法是一种直观、简便的纺织品抗拉强度检测方法,通过观察纺织品在拉伸过程中的形变情况,可以判断其抗拉强度,具体步骤包括准备样品、对样品进行显微镜观察、记录数据等,该方法适用于对样品进行微观层面的观察和分析。

化学分析法

化学分析法是一种基于化学成分分析的方法,可以用于检测纺织品的化学成分和性能,通过分析纺织品的化学成分,可以确定其抗拉强度是否符合标准,具体步骤包括样品准备、化学成分分析、数据记录等,该方法适用于对纺织品的整体性能进行全面评估。

实际案例分析

以某品牌纺织品为例,介绍其抗拉强度检测的实际案例。

样品准备

该品牌准备了一批不同规格和材质的纺织品样品,包括棉质面料、涤纶纤维等。

拉伸试验机检测法

使用拉伸试验机对该批样品进行抗拉强度测试,根据测试结果,该品牌发现其中一些样品的抗拉强度较低,需要进行进一步的质量控制。

显微镜检测法

通过显微镜观察,发现这些抗拉强度较低的样品在拉伸过程中出现了明显的形变现象,进一步分析发现,这些样品中可能存在纤维断裂或纤维结构破坏等问题。

化学分析法

对该批样品进行化学成分分析,发现其中一些样品的化学成分不符合标准,进一步分析发现,可能是由于纤维原料质量不佳或生产工艺控制不严格等原因导致的。

纺织品抗拉强度检测对于保证纺织品的质量和性能至关重要,本文介绍了拉伸试验机检测法、显微镜检测法和化学分析法等多种纺织品抗拉强度检测方法,并结合实际案例进行分析,在实际应用中,应根据样品的特点和需求选择合适的检测方法,以确保检测结果的准确性和可靠性,还需要加强质量控制和检验流程的管理,以确保纺织品的质量和性能符合标准要求。

Articles related to the knowledge points of this article: