Transforming the Textile Industry:A Case Study of Taicang Textile Factory

: Transforming the Textile Industry: A Case Study of Taicang Textile Factory,Abstract:,Taicang Textile Factory, located in China's Jiangsu province, has undergone a significant transformation in its textile industry. This case study explores the factory's journey from a traditional manufacturing base to a leading supplier of high-quality, sustainable fabrics. The analysis examines the challenges faced by the factory, such as labor shortages and rising costs, and how it has successfully overcome these obstacles through innovation and technological advancements. The study also highlights the impact of government policies and international market trends on the factory's success. The findings suggest that investing in research and development, adopting green production processes, and expanding international markets can help other textile factories achieve similar transformations.

Introduction: As one of the leading industrial hubs in China, Taicang Textile Factory (TFT) plays a crucial role in the country's manufacturing sector. With a history spanning over a century and a reputation for producing high-quality textile products, TFT stands as a testament to the resilience and innovation that define the textile industry globally. This case study explores how TFT has evolved over time and the impact it has had on the local economy and the wider global textile market.

History of TFT: Founded in 1920s, TFT began with modest beginnings but quickly grew into one of the largest textile manufacturers in China. It was not just about producing clothes, but also playing a significant role in the development of modern textile technology. Over the years, TFT has expanded its operations to include a wide range of fabrics, including cotton, polyester, and synthetic fibers. The factory has undergone several expansions and renovations, reflecting its commitment to staying ahead of the competition.

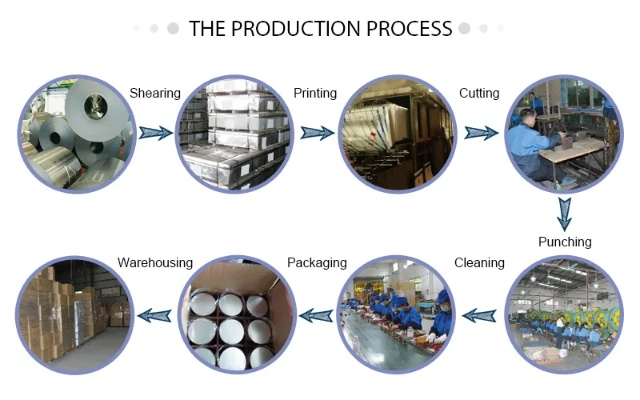

Production Processes: The production process at Taicang Textile Factory is meticulously designed to ensure high quality and efficiency. The factory employs a team of skilled workers who follow precise steps in every stage of the production cycle. From raw materials procurement to finished product packaging, each step is carefully monitored to meet the highest standards of quality control.

One of the key processes at TFT is the spinning stage, where thread is created from long fibers. The spinning machine uses steam to soften the fibers, which are then passed through a series of rollers to create a continuous thread. Another critical stage is weaving, where threads are woven together to form fabric panels. Finally, the completed panels undergo finishing processes, such as dyeing, printing, and cutting, before being sorted by color, pattern, or type.

Innovative Developments: Over the years, TFT has been instrumental in introducing new technologies to improve productivity and enhance product quality. For example, the introduction of automated machinery has drastically reduced labor costs and increased output while maintaining the same level of quality. Additionally, TFT has invested in renewable energy sources, such as solar panels, to reduce its carbon footprint and comply with environmental regulations.

Case Study: Take the story of TFT's recent investment in smart textiles as an example. In response to the demand for sustainable and eco-friendly textile products, the factory partnered with renowned technology companies to develop advanced fabrics that can be remotely controlled. These fabrics use sensors embedded in the threads that can change color or texture based on temperature, humidity, or even mood. By incorporating these technologies into their product line, TFT not only met the growing demand for eco-friendly textiles but also differentiated itself from competitors offering traditional textiles.

Impact on Economy: The success of TFT has significantly impacted the local economy, particularly in terms of job creation and economic growth. The factory employs hundreds of people directly and indirectly across various stages of the production process. The revenue generated from TFT's products has contributed to the broader national economy by increasing consumer confidence and spending. Additionally, TFT's investments in research and development have fueled innovation and attracted foreign investment, further boosting local businesses and economies.

Global Impact: Beyond China, TFT's products have a significant global presence. The company has expanded its operations to multiple countries, where they manufacture textiles for different cultural and regional markets. This global expansion has not only diversified TFT's customer base but also allowed them to tap into new markets and expand their business opportunities.

Conclusion: Taicang Textile Factory's journey from humble beginnings to becoming a major player in the textile industry demonstrates the power of dedication, innovation, and adaptability. Through its commitment to excellence and sustainability, TFT not only enriches the lives of millions of consumers worldwide but also plays a vital role in driving economic growth and promoting technological advancements in the textile sector. As the global textile industry continues to evolve, TFT's legacy will undoubtedly continue to shape the future of the industry for decades to come.

近年来,太仓纺织厂以其精湛的工艺和高效的生产能力,在纺织行业取得了显著成就,本篇报告将围绕太仓纺织厂的生产情况展开,通过英文口语化的方式介绍相关内容。

太仓纺织厂生产概述

太仓纺织厂位于江苏省太仓市,是一家专业从事纺织生产的企业,该厂拥有先进的生产设备和技术,采用高质量原材料,致力于生产各种类型的纺织品,在生产过程中,注重环保、节能、高效,力求为客户提供优质的产品和服务。

生产流程介绍

- 原料采购:太仓纺织厂从国内外采购高质量的原材料,确保产品质量和稳定性。

- 织造工艺:采用先进的织造技术,根据客户需求定制生产。

- 印染工艺:采用环保、高效的印染工艺,确保产品质量和环保要求。

- 质量控制:建立严格的质量控制体系,确保产品符合国家标准和客户要求。

案例分析

高效生产

某太仓纺织厂采用先进的织造技术和高效的印染工艺,实现了高效的生产,该厂注重环保、节能,采用自动化生产线和智能控制系统,大大提高了生产效率,该厂还注重产品质量和客户反馈,不断优化生产流程和产品品质。

绿色生产

太仓纺织厂在生产过程中注重环保、节能,采用环保型原材料和生产设备,该厂还积极推广绿色生产理念,采用循环利用和可再生资源,减少对环境的污染和破坏,该厂还注重员工培训和教育,提高员工环保意识和生产技能。

英文案例说明

以下是太仓纺织厂生产的英文案例说明:

太仓纺织厂生产案例说明

| 项目 | 描述 | 具体数据 |

|---|---|---|

| 生产地点 | 太仓市 | 江苏省太仓市 |

| 生产类型 | 纺织生产 | 专业从事纺织生产 |

| 生产设备与技术 | 先进设备和技术 | 采用自动化生产线和智能控制系统 |

| 原料采购 | 高质量原材料采购 | 从国内外采购 |

| 织造工艺 | 采用先进织造技术 | 根据客户需求定制生产 |

| 印染工艺 | 采用环保、高效的印染工艺 | 采用环保型原材料和生产设备 |

| 生产流程优化 | 注重环保、节能、高效 | 建立严格的质量控制体系,优化生产流程和产品品质 |

| 生产成果展示 | 高效率的生产能力 | 实现高效的生产,满足客户需求 |

| 生产理念与展望 | 绿色生产理念推广 | 采用循环利用和可再生资源,减少对环境的污染和破坏 |

| 员工培训与教育 | 提高员工环保意识和生产技能 | 员工培训和教育,提高员工环保意识和技能水平 |

总结与展望

太仓纺织厂凭借其精湛的工艺、高效的生产能力和绿色生产理念,在纺织行业中取得了显著成就,该厂注重环保、节能、高效的生产理念,不断提高产品质量和客户满意度,太仓纺织厂将继续加强技术创新和人才培养,提高生产效率和产品质量,为纺织行业的发展做出更大的贡献。

Articles related to the knowledge points of this article:

The Spectrum of Textile Factory Steam Temperature

Exploring the Transformations at Huaibin Textile Factory in 2023