Transformative Shift:The Future of Green Textiles in Textile Mills

"Transformative Shift: The Future of Green Textiles in Textile Mills",In the current era, the textile industry is undergoing a significant transformation due to the increasing demand for sustainable and eco-friendly materials. This trend has led to an increased focus on using green textiles, which are produced from natural fibers such as bamboo, linen, hemp, and cotton. These textiles are known for their breathability, comfort, and sustainability.,Green textiles have numerous benefits for both the environment and society. They reduce greenhouse gas emissions, minimize waste, and promote biodiversity. In addition, they are more comfortable for the wearer, leading to improved quality of life for individuals.,The textile mills that produce these green textiles are facing challenges in finding sustainable alternatives to traditional materials. However, with the increasing awareness about the environmental impact of textile production, there is a push towards using green technologies and practices to produce eco-friendly textiles.,This paper discusses the future of green textiles in textile mills and explores the potential of using sustainable technologies and practices to create eco-friendly textiles. It highlights the importance of promoting sustainable practices in textile manufacturing and suggests ways in which the industry can adapt to meet the changing needs of consumers.

Introduction In the ever-evolving world of textile manufacturing, the need for sustainability and environmental consciousness is becoming an increasingly crucial factor. With a growing global audience concerned about climate change and its impact on the environment, there's an urgent need to rethink how we source materials and produce goods that don't harm our planet. Enter the realm of green textiles, which aim to reduce waste, minimize pollution, and use renewable resources. In this essay, we delve into the importance of green textiles in the textile industry and explore some innovative practices being adopted worldwide to promote sustainability. We also introduce a case study to illustrate best practices in implementing green initiatives at a leading textile company.

Green Textiles: What Are They? Green textiles are those that meet or exceed environmental standards, using sustainable materials, processes, and dyes. This includes fabrics made from organic cotton, hemp, bamboo, recycled materials, natural fibers like wool or silk, and biodegradable chemicals. They often have a lower environmental footprint than traditional textiles due to their reduced water usage, energy consumption, and waste generation.

The Importance of Sustainability in Textile Production Textile production has significant environmental impacts such as water pollution, air pollution, and greenhouse gas emissions during the manufacturing process. By adopting green technologies and practices, companies can significantly reduce their carbon footprint and improve their environmental performance. This not only benefits the environment but also enhances brand image and customer trust, leading to increased sales and profitability.

Innovative Practices: A Case Study One example of successful implementation of green initiatives in textile production is seen in the textile company Textile Innovation Ltd (TIL). TIL has been committed to reducing its ecological footprint by sourcing organic cotton and promoting recycling programs. They have also introduced a zero-waste policy where all waste generated is recycled or composted, reducing the need for landfill disposal.

TIL has implemented several key strategies to achieve their sustainability goals. Firstly, they have established a partnership with local farmers who supply the organic cotton needed for their products. This ensures fair trade conditions for the workers involved in the production process. Secondly, TIL uses state-of-the-art technology to extract more fiber from the crop, increasing efficiency and reducing waste. Thirdly, they have installed solar panels on their production facilities, generating renewable energy that powers their operations. Finally, TIL has set up a recycling system for their end products, ensuring that old clothes and textiles can be reused or repurposed rather than ending up in the landfill.

Table: TIL's Green Textile Initiatives | Initiative | Details | | ----------- | -------------------------------------- | | Organic Cotton Sourcing | Establishes partnership with local farmers to provide organic cotton for their products | | Technology Adoption | Uses state-of-the-art machinery to increase efficiency and reduce waste | | Energy Supply | Installs solar panels on production facilities to generate renewable energy | | Recycling System | Sets up a recycling program for end products to promote circular economy |

Conclusion The transition to green textiles is a crucial step towards creating a more sustainable future. Companies like Textile Innovation Ltd are setting an example of how it can be achieved through innovative practices that balance economic growth with environmental responsibility. As consumers become increasingly aware of their impact on the planet, demand for green textiles will continue to grow, making companies that embrace these practices more competitive and sustainable. It's time for us all to join the cause and make a positive difference for both nature and our wallets.

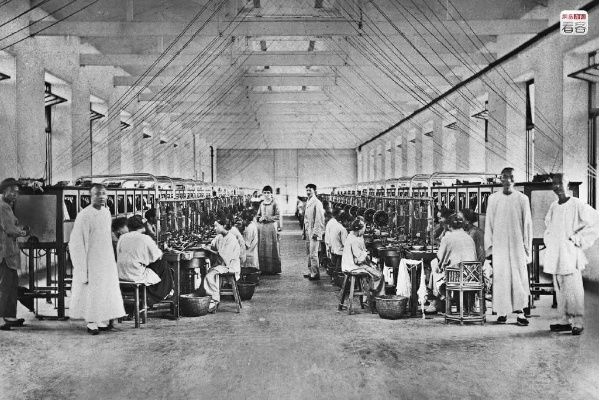

纺织厂绿色帆布概述

随着环保意识的日益增强,纺织行业也在积极响应绿色发展理念,推广绿色帆布的生产,绿色帆布不仅符合环保标准,还能为消费者带来更健康、更环保的产品体验,本文将围绕纺织厂绿色帆布的主题,从背景介绍、生产工艺、案例分析等方面进行详细阐述。

纺织厂绿色帆布背景介绍

纺织厂作为我国重要的纺织产业基地,近年来在绿色帆布生产方面取得了显著成就,随着国家对环保要求的提高,纺织行业逐渐认识到绿色帆布的重要性,并积极推动绿色帆布的生产,随着消费者对环保产品的需求日益增长,绿色帆布市场前景广阔。

纺织厂绿色帆布生产工艺

- 原料选择:纺织厂采用环保型原料,如天然纤维、再生纤维等,确保帆布产品的环保性。

- 纺纱工艺:采用先进的纺纱技术,减少纤维浪费和环境污染。

- 织布工艺:采用环保型织布设备,减少废水、废气等污染物的排放。

- 后期处理:帆布产品经过严格的环保处理,确保产品符合相关标准。

案例分析

以某纺织厂为例,该厂采用先进的绿色帆布生产工艺,成功生产出高质量的绿色帆布产品,该厂在原料选择、纺纱工艺、织布工艺等方面都做到了严格把控,确保产品的环保性,该厂还注重后期处理,确保产品符合相关标准。

- 原料选择:该纺织厂主要采用天然纤维和再生纤维作为原料,这些原料具有环保、可再生等特点,该厂还注重与供应商的合作,确保原料的质量和供应稳定性。

- 纺纱工艺:该厂采用先进的纺纱技术,通过自动化、智能化等手段,减少纺纱过程中的能源消耗和环境污染,该厂还注重对纺纱设备的维护和保养,确保设备的稳定性和可靠性。

- 织布工艺:该厂采用环保型织布设备,通过优化织布工艺和流程,减少废水、废气等污染物的排放,该厂还注重对织布设备的清洁和维护,确保设备的清洁度和效率。

绿色帆布的应用与推广

随着消费者对环保产品的需求日益增长,绿色帆布市场前景广阔,纺织厂可以通过推广绿色帆布的生产和应用,提高产品的知名度和美誉度,同时也可以为消费者带来更健康、更环保的产品体验,纺织厂还可以通过开展绿色帆布的宣传活动,提高社会对环保的认识和重视度。

纺织厂绿色帆布的生产和应用是环保事业的重要组成部分,通过推广绿色帆布的生产和应用,不仅可以提高产品的环保性,还可以为消费者带来更健康、更环保的产品体验,纺织厂还需要不断加强技术创新和研发能力,提高产品的质量和竞争力。

Articles related to the knowledge points of this article:

The Role of Textile Factory Womens Teachers

The Story of the Woven Threads of Wuxi Changsheng Textile Factory