Understanding the Power of SPI in Textile Technology

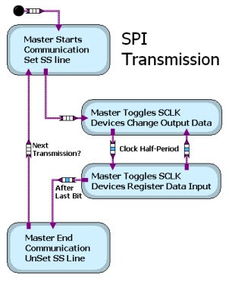

Introduction: The textile industry is an essential sector, responsible for producing a wide range of fabrics that adorn our clothing, furnishings, and other items. As such, it plays a critical role in our daily lives and has a profound impact on the global economy. One crucial aspect of this industry is Spinning Process Induced Polarization (SPI), which refers to the process by which textile fibers are processed and manipulated to enhance their mechanical properties, such as strength, flexibility, and durability. In this guide, we will delve into the importance of SPI in textile technology, its various techniques, and how it has revolutionized the fashion landscape.

Spinning Process Induced Polarization (SPI) in Textile Technology: SPI is a complex process that involves the manipulation of fibers during spinning to enhance their polarity. This process is crucial for creating high-quality yarns, which are then used to make fabrics that meet specific functional requirements.

-

Basics of SPI: SPI is a technique that involves altering the surface charge of fibers during spinning. It is typically achieved by introducing a chemical treatment or a physical process like electrospinning. The resulting fibers have a polarized structure with a higher surface area, leading to improved adhesion, wear resistance, and overall performance.

-

Techniques: There are several techniques used to induce SPI in textile fibers, including:

- Chemical treatments: These involve applying chemicals to the fibers before spinning, which can alter their surface properties. For example, mercerizing involves using alkali to remove the natural protein coating from the fibers, allowing them to be more receptive to chemical treatments.

- Electrospinning: This technique uses high voltage to spin fibers from polymer solutions. By adjusting the voltage and solution parameters, it is possible to achieve varying degrees of polarity within the fiber structure.

- Electroless plating: This method involves depositing metal onto the fiber surface, which can also lead to a polarized effect. However, it's important to note that electroless plating can introduce defects into the fibers due to the high temperatures used during the process.

Benefits of SPI: SPI offers several benefits to the textile industry, including:

- Improved mechanical properties: Fibers with induced SPI exhibit enhanced strength and flexibility, making them ideal for applications such as sportswear and athletic gear.

- Increased durability: The enhanced surface area caused by SPI allows for better adhesion between fibers, reducing fraying and tearing, and increasing the overall lifespan of the fabric.

- Improved aesthetics: With increased surface area, the fibers produced by SPI can have a more vibrant appearance, enhancing the aesthetic appeal of textile products.

Case Study: One example of the impact of SPI on textile technology can be seen in the case of Tencel®, a brand of wood pulp fibers developed by Lenzing GmbH & Co. KG. Tencel™ was introduced in the late 1980s, and over time, it evolved to become one of the most recognizable brands in the market. The success of Tencel™ owes much to the introduction of SPI technology, which allowed Lenzing to produce high-performance, eco-friendly fabrics that met changing consumer preferences for sustainability and eco-friendly materials. By incorporating SPI, Lenzing was able to create Tencel™ that not only offered superior performance but also had a unique, silky texture that set it apart from its competitors.

Conclusion: In conclusion, Spinning Process Induced Polarization (SPI) is a crucial aspect of textile technology that has revolutionized the way we produce and use textiles. From improving mechanical properties to enhancing aesthetics, SPI has transformed the industry and opened up new opportunities for innovation and development. As the demand for sustainable, eco-friendly textiles continues to rise, SPI will undoubtedly play a significant role in shaping the future of the textile industry.

在当今全球化的纺织品市场中,纺织品的质量和功能性越来越受到消费者的关注,SPI(Specialty Textiles Industry)作为纺织品行业的重要组成部分,其在纺织品领域的应用和发展趋势日益凸显,本文将围绕SPI在纺织品领域的应用展开讨论,并通过英文案例说明来进一步阐述其重要性。

SPI在纺织品领域的重要性

-

技术创新:SPI通过采用先进的纺织技术,提高了纺织品的性能和品质,采用高纤维含量、高弹性、高耐磨性的面料,提高了纺织品的抗皱性、透气性和舒适度。

-

环保可持续性:随着消费者对环保和可持续性的关注度不断提高,SPI在纺织品中更多地融入了环保元素,如使用可降解材料、减少化学添加剂的使用等,从而提高了纺织品的环保性能。

-

市场需求:随着消费者对个性化、高品质、高性价比纺织品的需求增加,SPI在纺织品领域的应用也越来越广泛,在服装、家居装饰、户外用品等领域都有其应用。

英文案例说明

以某知名纺织品品牌为例,该品牌在纺织品领域采用了SPI技术,具体应用如下:

-

产品创新:该品牌采用新型的高纤维面料,具有出色的抗皱性、透气性和舒适度,这种面料不仅提高了纺织品的品质,同时也符合了现代消费者对环保和可持续性的需求。

-

环保材料使用:该品牌在生产过程中采用了可降解材料,减少了化学添加剂的使用,这不仅符合了环保和可持续性的要求,同时也提高了纺织品的环保性能。

SPI在纺织品领域的应用

-

纺织品面料:SPI在纺织品面料方面有着广泛的应用,采用高纤维含量、高弹性、高耐磨性的面料可以制作出各种服装、家居装饰、户外用品等,这些面料不仅具有优良的性能,同时也符合了现代消费者的需求。

-

功能性纺织品:随着消费者对纺织品功能的关注度不断提高,SPI在功能性纺织品方面也有着广泛的应用,采用特殊纤维制成的内衣、袜子等,具有保暖、透气、舒适等特性,满足了消费者对个性化、高品质、高性价比纺织品的需求。

英文表格补充说明

以下是关于SPI在纺织品领域应用的英文表格补充说明:

| 项目 | SPI应用情况 | 英文说明 |

|---|---|---|

| 纺织品面料 | 采用新型高纤维面料 | 采用先进纺织技术,提高面料性能和品质 |

| 环保材料使用 | 使用可降解材料 | 在生产过程中减少化学添加剂的使用,符合环保和可持续性要求 |

| 功能纺织品 | 应用特殊纤维制成的内衣、袜子等 | 根据消费者需求制作个性化、高品质、高性价比纺织品 |

| 市场趋势 | 随着消费者需求增加,应用范围扩大 | 随着市场需求增加,SPI在纺织品领域的应用越来越广泛 |

SPI作为纺织品行业的重要组成部分,其在纺织品领域的应用和发展趋势日益凸显,通过采用先进的纺织技术、环保可持续性材料以及个性化功能纺织品等手段,可以满足消费者对纺织品高质量、高性能的需求,随着消费者对纺织品需求的不断增加,SPI在纺织品领域的应用也将越来越广泛。

Articles related to the knowledge points of this article:

The Evolution of Silin Textiles:Innovation,Sustainability,and Global Impact