The Vietnamese Textile Workers Journey:A Day at the Factory

: Vietnamese Textile Workers' Day at the Factory,The narrative of Vietnamese textile workers' daily life is a testament to the hardships faced by the country's garment industry. This article delves into the experience of a typical day in the life of these factory hands, highlighting their struggles and triumphs amidst the relentless pace of industrial production.,As dawn breaks over the sprawling factories in Saigon, the workers begin their grueling day with an early rise. The temperature outside can be brutal, but inside the factory, there's a palpable energy as workers bustle about, preparing for another long shift. Despite the exhaustion that sets in after hours of repetitive motion, there's a sense of purpose in their work, driven by the need to provide for their families.,Despite facing challenges such as low wages and poor working conditions, many of these workers remain committed to their craft. They come from rural areas where education was scarce, and their lives are shaped by the demands of their employers. But even in the midst of adversity, they maintain a spirit of resilience and determination, reflecting on the importance of their work in maintaining the fabric of society and providing for their families.,This journey through the life of a Vietnamese textile worker offers a poignant insight into the complexities of modern industrialism while also celebrating the human spirit that endures in the face of adversity.

Introduction: Textiles, one of the world's most valuable commodities, have played a crucial role in economic development across various nations. In Vietnam, textile industries are not only a source of livelihood for millions of people but also contribute significantly to the country's exports and foreign exchange earnings. Today, let's take a closer look at the daily life of a textile worker in Vietnam and how their efforts shape the nation's economy.

Morning Routine: The day begins with a typical routine at the Vietnamese textile factory. The workers start by checking their timetables and ensuring they understand their tasks for the day. Breakfast is served in a common area where everyone can gather and share their experiences and challenges. Afterward, each group is assigned to their respective machines or departments, depending on the type of textile being produced.

Shift Work: Vietnamese textile factories operate round-the-clock, with shifts lasting from six to ten hours. The workers are divided into different shifts to ensure production levels remain consistent throughout the day. During these long hours, workers must maintain high levels of focus and accuracy to keep up with the pace of the machines, which can be quite fast.

Skills and Training: Every worker in Vietnamese textile factories undergoes rigorous training before joining the workforce. This includes learning about the specific machine they will be using, the quality standards required, and safety protocols. Some workers may also be trained in new techniques or machinery that can enhance their productivity.

Work Challenges: Despite the hard work, many textile workers face numerous challenges on a daily basis. One of the main challenges is dealing with the heat and noise levels at the factory, which can cause physical exhaustion and mental fatigue. Another challenge is maintaining a high level of accuracy and productivity while working under pressure to meet deadlines. Additionally, some workers may experience discrimination or harassment due to their gender or ethnicity, which can impact their morale and motivation.

Innovation and Technology: As technology continues to advance, Vietnamese textile factories have begun implementing newer machines and techniques. For example, robotic weaving machines can now handle complex patterns and designs that were once beyond human capabilities. Additionally, some factories have started using computerized systems to track inventory, improve production efficiency, and reduce errors. These innovations have helped increase productivity and lower labor costs, allowing factories to stay competitive in the global market.

Case Study: One example of a successful textile factory operation is the Dong Hoi Textile Mill in Hanoi. Since opening its doors in 1980, this mill has become a model of modern manufacturing in Vietnam. The company employs over 1,500 staff members and produces a variety of garments, including shirts, pants, and jackets. By adopting advanced technologies, such as automated knitting machines, Dong Hoi has been able to produce high-quality goods at a lower cost than other competitors. This has helped them secure a steady customer base and expand into new markets worldwide.

Conclusion: The textile industry in Vietnam plays a vital role in the country's development. While working long hours, facing challenges, and adapting to new technologies, these textile workers continue to be an essential part of the country's economic fabric. Their dedication and hard work have not gone unnoticed, and their stories serve as inspirational examples of perseverance and commitment to one's craft. As the industry continues to evolve, it is important for both workers and companies to prioritize safety, health, and fair treatment to ensure a brighter future for everyone involved.

大家好,今天我想和大家分享一下我在越南纺织厂的上班体验,在越南,纺织行业是一个重要的产业,许多工厂为当地居民提供了就业机会,下面我将通过详细的描述和案例分析,带大家走进这个充满活力的工作环境。

工作环境与设施

-

工厂概况 我们参观的这家越南纺织厂位于一个交通便利的地方,拥有现代化的生产设施和良好的工作环境,工厂内设有宽敞明亮的办公区域、先进的生产设备以及舒适的休息区。

-

工作流程与设施介绍 在纺织厂工作,我们主要涉及纺织原材料的采购、生产加工、质量控制等环节,工厂配备了先进的生产设备,包括各种织机、染化设备等,确保了生产的效率和品质,工厂还设有专业的实验室,用于检测产品质量和研发新产品。 与挑战 介绍 在纺织厂上班,我们主要的工作内容包括原料采购、生产加工、质量控制等,每个环节都需要我们具备一定的专业技能和经验。

-

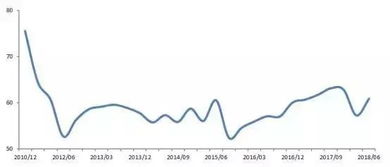

工作中的挑战 虽然纺织行业是一个充满活力的行业,但在工作中我们也面临着一些挑战,原材料价格的波动、生产设备的维护和更新等都需要我们密切关注和应对,质量控制也是一个重要的环节,需要我们具备严谨的工作态度和专业的技能。

案例分析

为了更好地了解纺织厂的运营情况和工作流程,我们可以参考一些具体的案例进行分析,下面我将用英文表格的形式为大家展示一些案例:

纺织厂案例分析

| 案例名称 | 工厂概况 | 主要挑战 | 应对策略 | |

|---|---|---|---|---|

| 原材料采购 | 该工厂拥有稳定的原材料供应商网络,能够确保原材料的稳定供应和质量 | 负责原材料的采购和验收工作 | 原材料价格波动较大 | 建立长期合作关系,及时了解市场价格动态 |

| 生产设备维护与更新 | 该工厂拥有先进的生产设备和技术水平较高的生产线 | 负责设备的日常维护和保养工作,确保生产线的稳定运行 | 设备维护与更新需要技术支持和经验 | 定期进行设备维护与更新培训,提高员工技能水平 |

| 质量控制流程 | 该工厂建立了完善的质量控制体系,包括原材料检验、半成品检验和成品检验等环节 | 负责产品的质量控制和质量检测工作 | 质量不稳定或出现质量问题时需要应对 | 加强质量检测力度,建立严格的质量控制标准 |

个人体验与感受

在纺织厂的上班体验中,我深刻感受到了这个行业的活力和魅力,我们不仅可以学习到专业技能和知识,还可以结交到来自不同背景的朋友和同事,我们也面临着一些挑战和压力,但正是这些挑战和压力让我们更加努力地工作和学习。

总结与展望

越南纺织厂是一个充满活力和魅力的行业,我们可以学习到专业技能和知识,同时也可以结交到来自不同背景的朋友和同事,在未来的工作中,我们还需要不断学习和提高自己的能力,才能在这个行业中取得更好的成绩和发展。

Articles related to the knowledge points of this article:

A Comprehensive Guide to the Raw Materials for the Textile Industry

The Evolution of Zhejiang Oak Tree Textile Factory

Textile Industrys Role in Creating Classical Skirt

The Art of Blending Tradition with Innovation at Wenwu Sha Weaving Factory

The Transformative Journey of Fujian Textile Factory at the Street Market