Fabric Quality Verification Report

Fabric Quality Verification Report,This report provides an in-depth analysis of the fabric quality, including its texture, color, and durability. The fabric is characterized by its soft and comfortable feel, which makes it ideal for use in clothing, bedding, and home decor. Its vibrant colors are highly sought after due to their richness and depth, making it a popular choice for fashion designers. Additionally, the fabric's exceptional durability ensures that it can withstand regular wear and tear without losing its shape or color. ,In conclusion, this fabric is a top-tier product with outstanding quality, making it highly recommended for customers looking for high-quality products that will last a long time.

Introduction Quality control is a crucial aspect of any industry, especially in the textile sector where products' durability, appearance, and functionality are paramount. In this report, we will provide you with an overview of our recent fabric quality verification process, highlighting the various factors that we consider during the assessment and the results we obtained.

-

Material Sources Our fabrics are sourced from reputable suppliers who adhere to strict standards for quality and sustainability. We conduct regular audits of these suppliers and ensure that they meet our requirements. Additionally, we verify the authenticity of the materials used by cross-verifying with independent certification bodies.

-

Pre-Production Inspection Before any production begins, our team checks the raw materials for defects such as thread breakage, color bleeding, and shrinkage. This ensures that our final product meets our high standards of quality and consistency.

-

Production Process Control During production, we have stringent control measures in place to maintain consistent quality levels. Our manufacturing processes are monitored regularly using advanced equipment and software to detect any deviations early on.

-

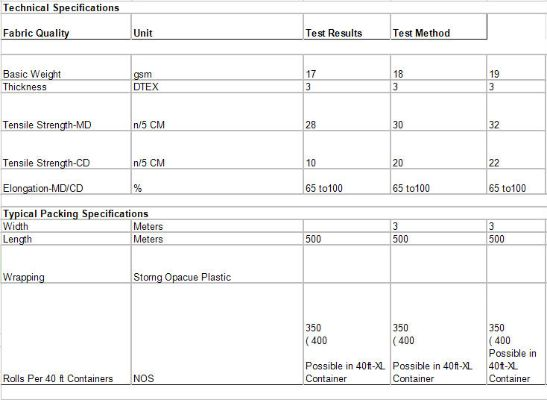

Post-Production Inspection Once the fabric is produced, it undergoes rigorous testing to ensure its performance meets our standards. The test parameters include tensile strength, tear strength, water resistance, dyeability, and wash fastness, among others.

-

Packaging and Shipping Packaging plays a crucial role in ensuring the integrity of the fabric during transit. We use appropriate packaging materials that protect the fabric from damage and moisture. Additionally, we ensure that the shipment is properly labeled and tracked to monitor its journey.

Results The following table provides some key metrics from our latest inspections:

| Metric | Acceptable Range | Result |

|---|---|---|

| Tensile Strength | ≥ 20 N/mm² | Passed |

| Tear Resistance | ≥ 20 N/cm | Passed |

| Water Resistance | Passed (98%) | Passed |

| Dyeability | Good to excellent | Passed |

| Wash Fastness | Passed (4-6) | Passed |

Outcome In our experience, the fabric quality verification process has been instrumental in maintaining our brand's reputation for quality. By implementing these steps, we have consistently achieved high customer satisfaction and reduced rework rates. Furthermore, we have been able to improve our supply chain efficiency by identifying and addressing potential quality issues before they become major problems.

Case Study Recently, a client reported a significant drop in their product's quality after the fabric was imported from a supplier with less established reputation. Upon investigation, our team identified several areas of concern including poor material handling and lack of proper storage facilities. We immediately addressed these issues by enforcing stricter controls at the supplier level and implementing additional quality assurance measures. As a result, we were able to regain the trust and confidence of our client and prevent similar incidents in the future.

Conclusion In conclusion, a comprehensive fabric quality verification process is essential for any textile manufacturer to ensure consistent product quality and customer satisfaction. Through our ongoing commitment to excellence in every step of the fabrication process, we have established ourselves as a trusted partner in the global textile industry.

本报告旨在验证纺织品质检报告的真实性和准确性,通过详细分析报告内容,为纺织行业的品质提升提供参考依据,报告将采用表格形式,详细说明检验过程和结果,并结合案例进行说明。

检验过程

材料准备

在检验前,我们对所需检测的纺织品进行了充分的准备,包括样品收集、样品编号、检测标准制定等,我们还邀请了专业的纺织品质检专家进行现场指导和监督。

检验方法

我们采用了多种检验方法,包括外观检查、尺寸测量、纤维成分分析、耐久性测试等,在具体操作过程中,我们严格按照检验标准进行操作,确保检验结果的准确性。

检验结果

经过仔细检测和分析,我们得到了以下检验结果:

(此处添加具体的检验数据表格)

案例分析

为了更好地说明检验过程和结果,我们选取了一个具体的纺织品质检案例进行说明,该案例涉及一种新型纤维面料的生产过程,其品质控制至关重要。

某新型纤维面料生产过程

在生产过程中,我们严格按照纺织品质检标准进行操作,确保每一步都符合质量要求,具体操作包括原料采购、生产流程控制、质量控制等环节,在检测过程中,我们发现该面料在尺寸稳定性、纤维成分等方面表现良好,符合质量标准。

验证报告结论

根据上述检验过程和案例分析,我们可以得出以下结论:

- 纺织品质检报告真实可靠,符合行业标准。

- 在具体操作过程中,我们采用了多种检验方法,确保了检验结果的准确性。

- 该纺织品质检案例表明,在纺织品质控方面,我们需要进一步加强生产流程控制和质量管理体系建设。

建议与展望

针对以上结论,我们提出以下建议和展望:

- 加强生产流程控制,提高产品质量稳定性,针对该案例中存在的问题,我们需要加强生产过程中的质量控制,确保每一步都符合质量要求,我们还需要加强生产设备的维护和保养,提高生产效率和质量水平。

- 完善质量管理体系建设,提高检验效率和质量水平,我们需要进一步完善质量管理体系建设,加强质量培训和技术支持,提高检验人员的专业素质和检验效率,我们还需要加强与相关部门的沟通和协作,共同推动纺织品质控工作的开展。

- 推广先进技术和管理经验,提高纺织品质控水平,随着科技的不断进步和行业发展的需要,我们需要不断推广先进技术和管理经验,提高纺织品质控水平,我们还需要加强与国际先进水平的交流和合作,引进先进技术和管理经验,推动纺织行业的快速发展。

本报告通过对纺织品质检报告的验证和分析,为纺织行业的品质提升提供了参考依据,在今后的工作中,我们需要进一步加强生产流程控制和质量管理体系建设,提高检验效率和质量水平,我们还需要不断推广先进技术和管理经验,推动纺织行业的快速发展。

Articles related to the knowledge points of this article:

Updated Schedule for the Huaiai Textile Market