The Essential Components of Textile Printing Ink Applications

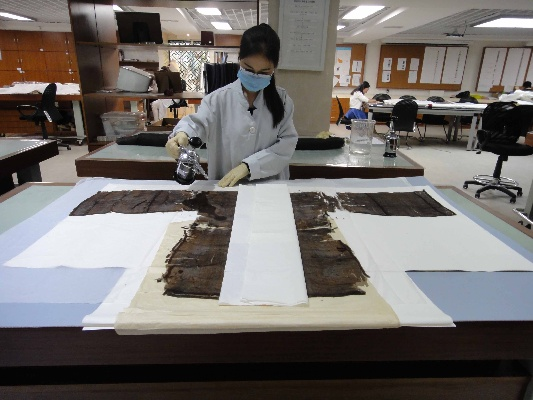

The application of textile printing ink is an essential process that involves the use of specific ink formulations to achieve desired results. The ink formulation typically includes pigments, binders, solvents, and other additives that work together to produce a stable and durable print on fabric.,Pigments are the primary components of the ink formulation responsible for the color and hue of the printed product. They come in various shapes and sizes, ranging from tiny particles to large flakes or powders, and their size affects how they spread out when applied to the fabric.,Binders play a vital role in holding the pigment particles together and providing the necessary cohesion for the ink to adhere to the fabric surface. They can be natural or synthetic polymers, such as resins or acrylics.,Solvents are added to the ink formulation to dissolve the binder and facilitate easy application to the fabric. They also help to reduce bubbles and improve the overall quality of the print.,Finally, there are various additives used in the ink formulation to enhance its performance. These include surfactants, thickeners, stabilizers, and dispersants, among others.,In summary, textile printing ink applications rely on the combination of essential components like pigments, binders, solvents, and additives that work together to create a durable and attractive print on fabric.

In the world of textile printing, there is a delicate balance between the beauty and functionality of the finished garment. One of the most critical elements that ensure the quality and durability of this artwork is the application of the correct type of ink. Today, we will explore the essential factors that should be considered when submitting an application for a textile printing ink, as well as some practical examples to illustrate how these considerations can impact the final outcome.

At its core, a textile printing ink application involves three main components: the inks themselves, the substrate (or fabric), and the printing equipment used for application. Each one plays a vital role in ensuring that the desired design is faithfully replicated on the garment.

The choice of inks is paramount, as it directly affects the color accuracy, durability, and overall aesthetic appeal of the garment. Common inks used for textile printing include water-based and solvent-based inks. Water-based inks, such as those made from polyurethane, are preferred for their eco-friendliness and longevity. However, they may not provide as vibrant a color range as solvent-based inks, which have better fastness properties and are more suitable for high-traffic areas like collars and cuffs.

The substrate is another critical component. It can range from cotton, silk, polyester, and even blended fabrics. Different substrates require different treatments before printing, such as pre-treatments or special coatings, to ensure proper adhesion and prevent damage during the printing process. For example, polyester fabrics often benefit from a surface treatment with a matte finish, while cotton fabrics may require a gloss finish to enhance their natural texture.

Lastly, the printing equipment used for application plays a pivotal role in achieving optimal results. Modern printing technologies offer various options, including digital printing, screen printing, pad printing, and letterpress. Each technique has its own set of advantages and limitations depending on the specific requirements of the project. For instance, digital printing offers high precision and speed, making it ideal for small runs or complex patterns, but it may not be as cost-effective for large-scale production. Screen printing, on the other hand, provides a more traditional approach with a higher level of control over the printing process, but it requires specialized equipment and expertise.

To illustrate how these factors can impact the final outcome, let's consider an example from our friends at Zara. When Zara designs a new season's collection, they carefully select the appropriate inks based on the fabric types and colors they intend to use. They also consider the printing equipment they want to utilize to achieve the desired effect. For example, they might opt for digital printing for their bright, bold designs on cotton fabrics and screen printing for their detailed graphics on polyester shirting. By carefully selecting these components, Zara ensures that their customers receive not only a stylish piece of clothing but also a product that reflects their brand values and meets consumer needs.

Another example comes from Uptown Clothing Company, where they specialize in eco-friendly textiles. When designing a new collection, UPC takes great care to choose sustainable inks and substrates to minimize environmental impact. They also invest in state-of-the-art printing equipment to ensure that their designs are printed accurately and consistently. This commitment to sustainability is reflected in the quality and longevity of their apparel, which has earned them a loyal customer base and a reputation for excellence.

In conclusion, when it comes to textile printing ink applications, there are several essential components that must be taken into account. From choosing the right ink type to considering the substrate and printing equipment, each decision can significantly influence the final outcome. By following industry best practices and staying up-to-date with the latest advancements in textile printing technology, businesses can create garments that not only meet consumer expectations but also stand out as true works of art.

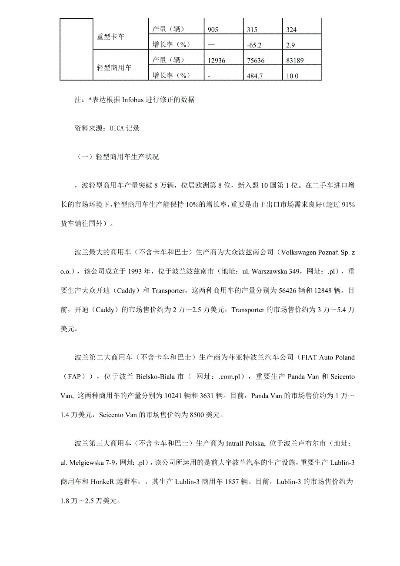

申报要素概述

纺织品印花油墨的申报涉及多个关键要素,以确保产品质量和安全性,以下是对申报要素的详细说明:

产品基本信息

产品名称:纺织品印花油墨 产品类型:印花油墨 主要用途:纺织品印花 生产厂家:XX公司

技术参数

(1)颜色稳定性:印花油墨应具备出色的颜色稳定性,确保印花图案的颜色持久且不易褪色。 (2)粘度:印花油墨应具有适当的粘度,以保证印花效果细腻且不易脱落。 (3)干燥速度:印花油墨应具有快速干燥特性,确保印花过程快速且高效。 (4)环保性能:申报时应提供环保性能检测报告,证明油墨符合环保标准。

质量标准

质量标准应包括以下方面:

(1)安全性能:确保产品无毒、无味、无污染,符合相关安全标准。 (2)环保性能:符合国家及行业标准,不含有害物质。 (3)使用性能:具有良好的印刷效果,色彩鲜艳、持久,不易脱落。

申报案例分析

某纺织品印花油墨申报实例

某纺织品印花油墨在申报过程中,提供了详细的检测报告和产品特性说明,该油墨具有出色的颜色稳定性、粘度和干燥速度,同时符合环保标准,在生产过程中,采用了环保材料和技术,确保产品质量和安全性,该油墨在纺织品印花领域得到了广泛的应用,得到了客户的好评。

其他纺织品印花油墨的特点和优势

其他纺织品印花油墨在申报过程中,还提供了其他特点和优势,该油墨具有快速干燥特性,可以在短时间内完成印花过程,提高了生产效率,该油墨还具有优秀的印刷效果和色彩鲜艳度,能够满足不同客户的需求,该油墨在市场上也获得了良好的口碑和销售业绩。

申报要素补充说明

产品原材料

(1)原材料质量:应提供原材料的质量检测报告,证明原材料符合相关标准。 (2)环保材料使用:申报时应强调使用环保材料的重要性,并说明使用环保材料的具体措施。

生产过程控制

(1)生产过程控制文件:应提供详细的生产过程控制文件,包括生产工艺、设备参数等。 (2)生产环境:应强调生产环境的清洁、卫生和安全,确保产品质量和安全性。

质量管理体系

质量管理体系应包括以下方面:

(1)质量检验流程:应明确质量检验流程,确保产品质量符合要求。 (2)质量保证措施:应提供质量保证措施的具体内容,包括原材料采购、生产过程控制等。

结论和建议

纺织品印花油墨的申报要素涉及多个方面,包括产品基本信息、技术参数、质量标准和申报案例等,在申报过程中,应注重产品质量和安全性、环保性能等方面,同时提供详细的检测报告和产品特性说明,还应强调生产过程控制和质量管理体系的重要性,以确保产品质量和可靠性,建议相关部门加强监管和检查力度,促进纺织品印花油墨行业的健康发展。

Articles related to the knowledge points of this article:

Sustainable Textile Recycling Solutions for a Greener Future

The Story of Sengze Yulong Textiles

Exploring the Market for Sustainable Textile Recycling in Fuzhou