The Role of Textile Adhesive in Modern Manufacturing

In today's highly competitive world where innovation is the name of the game, textile industries have evolved to incorporate advanced technologies that enhance efficiency and productivity. One such technology is the use of adhesives, especially textile adhesives, which play a vital role in the production process. In this article, we will explore the importance of textile adhesives, their applications, and how they are used across various industries.

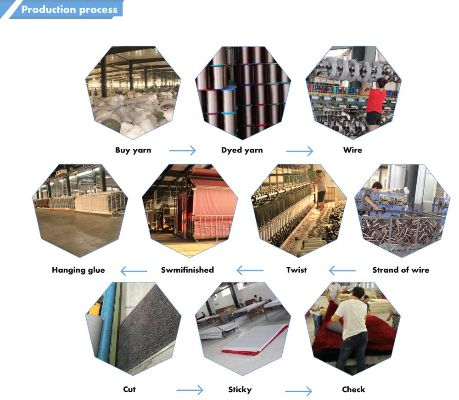

Textile adhesives are a crucial component in the manufacturing process as they serve as a strong bond between two or more surfaces. They help in fixing materials together, making them easier to handle, transport, and install. Adhesives also contribute to product quality by ensuring that products adhere properly and do not come off during use or storage. In the textile industry, adhesives are used to bond fabrics together, reinforce seams, and fix buttons and other fasteners onto garments.

One significant application of textile adhesives is in apparel manufacturing. Here, adhesives are used to attach fabric panels together, creating seamless designs that are both aesthetically pleasing and functional. For instance, using a suitable glue for denim jeans ensures that the fabrics stay together during washing, dyeing, and ironing processes. This results in durable and long-lasting products with excellent wear resistance.

Another area where textile adhesives are essential is in the production of sportswear. In athletic gear, the ability to bond different materials together is crucial for the integrity of the garment. Adhesives are used to secure patches onto jackets or pants without compromising comfort or performance. This is particularly important in sports equipment where the adhesive must be tough enough to endure heavy use yet flexible enough to conform to the body.

The textile industry uses a variety of adhesives, each with its unique properties and advantages. Waterborne adhesives, for example, are water-based and provide good adhesion strength but may require additional curing time compared to solvent-based adhesives. Solvent-based adhesives, on the other hand, offer superior flexibility and ease of handling but may be harder to remove once installed.

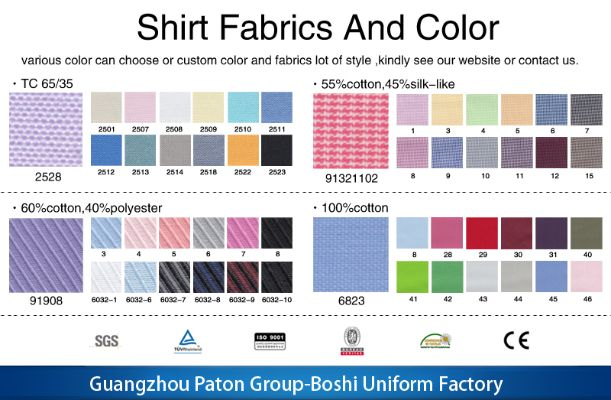

Adhesive selection is critical in ensuring that products meet customer expectations. For instance, in the fashion industry, it is important to choose adhesives that provide good durability and resistance to moisture, as these factors can affect the overall appearance and feel of clothing. Additionally, color matching is crucial when using colored adhesives; otherwise, discoloration or uneven application can lead to poor aesthetics.

In conclusion, textile adhesives play a vital role in the modern manufacturing process, enabling efficient and high-quality product assembly. From apparel to sportswear, adhesives ensure that materials remain securely attached, resulting in products that meet the needs of consumers while also being environmentally friendly and cost-effective. By understanding the benefits of textile adhesives and selecting appropriate types for specific applications, manufacturers can improve product quality, reduce waste, and enhance their bottom line.

Articles related to the knowledge points of this article:

Chinas Progressive Tariff Rate System for Imported Textile Goods

Amazons Limitations in Textiles:Why the Online Giant Cant Enter This Sector