A Comprehensive Guide to Understanding and Applying Textile Test Standards

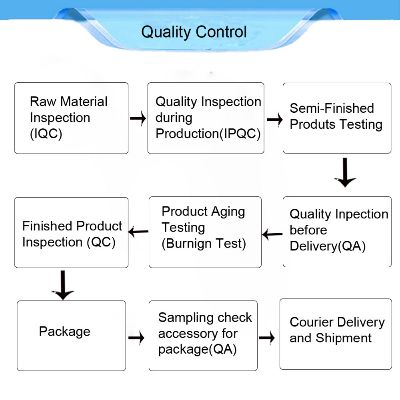

: A Comprehensive Guide to Understanding and Applying Textile Test Standards,Introduction: The textile industry is one of the most significant industries in the world, with a vast range of products that require rigorous testing to ensure quality. Textile test standards serve as a benchmark for assessing the performance of these products. This guide provides an overview of commonly used textile test standards, their applications, and how to apply them effectively.,Textile Test Standards:,1. ASTM D412: This standard covers the determination of yarn count, staple length, and other properties of yarns and fabrics. It is commonly used for measuring the strength and durability of textile products.,2. ISO 13605: This standard focuses on the measurement of elongation at break and tear strength of textile products. It is used to evaluate the resilience of textile materials under various stress conditions.,3. GB/T 4759: This standard is used to determine the color difference and hue angle between two textile samples. It is important in the color control and quality assurance of textile products.,Applications of Textile Test Standards:,1. Quality Control: Textile test standards play a crucial role in ensuring product quality. By using these standards, manufacturers can identify any defects or deviations in their products and take corrective action to improve their product performance.,2. Market Compliance: Textile test standards are essential for complying with market regulations and regulations. Companies that fail to meet these standards can face penalties and loss of market share.,3. Innovation: Textile test standards encourage innovation by providing guidelines for developing new textile products. Companies can use these standards to develop innovative materials and designs that meet customer needs and exceed expectations.,Conclusion: Textile test standards are critical tools for ensuring the quality and performance of textile products. By understanding these standards and applying them effectively, manufacturers can improve their product quality, comply with regulations, and drive innovation in the textile industry.

In the realm of textiles, there are an array of tests designed to ensure the quality, safety, and performance of materials used in clothing, home furnishings, and industrial applications. These standards are critical for manufacturers, designers, and consumers alike. The following is a guide to understanding some of the most common textile test standards worldwide, including examples from various industries.

-

ASTM D-412 (Standard Test Method for Tensile Strength of Cotton Fabrics) This standard tests the tensile strength of cotton fabric samples subjected to various tensions. It's important for textile manufacturers who produce clothing or household items made of cotton to comply with these standards. For instance, if you're looking for a shirt that will stand up to wear and tear, knowing that it meets ASTM D-412 standards can be reassuring.

-

ISO 5073 (International Organization for Standardization - Requirements for the Test of the Resistance to Bleed on Threads) Testing threads for bleeding resistance ensures that they don’t release dye when pulled apart. This is crucial for garments where colorfastness is a primary requirement, like sportswear or formal attire. Companies manufacturing apparel often have to adhere to ISO 5073, ensuring that their products meet this stringent standard.

-

ASTM D-489 (Standard Test Method for Tensile Strength of Polyester Fabrics) This standard measures the tensile strength of polyester fabric specimens under controlled conditions. Manufacturers of synthetic materials such as polyester often need to comply with this test to demonstrate that their fabrics can withstand repeated pulling without breaking or losing shape.

-

EN ISO 16511 (European Norms for the Test of the Resistance of Fabrics and Upholstery Fabrics to Staining) This European standard evaluates fabrics against staining resistance, which is particularly important for household textiles like curtains and blinds. It assesses how well fabrics resist the absorption of dyes and other stains, ensuring that they remain free from discoloration.

-

GB/T 18980-2006 (Chinese National Standard for the Quality Test of Nonwoven Fabrics) Similar to the above, this Chinese national standard covers nonwoven fabrics and provides a framework for evaluating their quality characteristics. Companies producing high-quality nonwoven goods, such as those found in bed linen or medical equipment, must follow these standards to ensure their products meet consumer expectations.

-

ASTM D-638 (Standard Test Method for Tensile Strength of Polyurethane Foams) For companies involved in the production of furniture, automotive, or other foam-based products, this test standard is crucial. It assesses the tensile strength of polyurethane foam samples to ensure that they can withstand compression without deforming or bursting.

-

ASTM F1694 (Standard Test Method for Tensile Strength of Wool and Other Natural Fibers) Fibers like wool are subject to specific testing methods to determine their tensile strength. For woolen goods or any natural fiber product, meeting ASTM F1694 standards is essential to ensure they maintain their integrity under stress.

-

ANSI Z38.1-2010 (American National Standard for the Test of the Resistance of Fabrics and Upholstery Fabrics to Bleaching) This American standard focuses on the resistance of textiles to bleaching. If your product includes fabrics that might come into contact with bleach solutions (like dishwasher detergents), you must adhere to ANSI Z38.1-2010 to prevent discoloration.

-

ISO 13125/1:2012 (EU) & ISO 13125:2007 (USA) (Economic Commission for Europe - ISO Test Methods for the Resistance of Clothes to Bleaching) For businesses involved in the fashion industry, these standards are crucial. They dictate the level of resistance a fabric needs to have to withstand the action of bleach. Companies that manufacture clothing intended for use in public places, especially hospitals, schools, and government buildings, must meet these standards to avoid health risks.

-

BS 1881 (British Standard for the Test of Elasticity of Plastic and Rubber) Companies producing plastic and rubber products, such as toys, car parts, or packaging materials, must adhere to BS 1881 to ensure their materials can stretch and recover after being stretched. This helps to prevent breakage and enhance product durability.

-

JIS K7115 (Japanese Industrial Standard for the Test of Stiffness of Nylon Fabrics) If your business deals with nylon fabrics, you must comply with JIS K7115 to demonstrate their flexibility and ease of use. Companies producing athletic wear, leisure wear, or other products made from nylon may have to adhere to these Japanese standards to ensure customer satisfaction.

-

EN ISO 14532:2014 (European Norms for the Test of Water Absorption and Rheological Properties by Means of Tenacity Testing) For businesses dealing with water-resistant or hydrophobic materials, these standards provide guidance on how to measure the water absorption and rheological properties of textiles. Companies making swimsuits, raincoats, or any product that comes into direct contact with water must adhere to this standard.

In conclusion, textile testing standards serve as benchmarks for quality assurance in the industry, ensuring that products meet the needs and expectations of consumers and stakeholders alike. By keeping track of these internationally recognized standards in your industry and staying updated with changes in regulations and technology, you can stay ahead of compliance requirements and drive innovation in your products and processes.

In this article, we will explore the various standards for testing the strength of textiles. We will also provide an English case study to illustrate these standards and their application.

纺织品测试力标准概述

纺织品测试力标准主要涉及纤维强度、织物抗拉强度、撕裂强度等多个方面的测试,这些标准旨在确保纺织品在各种使用场景下的性能符合预期,保障消费者的使用安全,以下是关于纺织品测试力的主要标准和相关标准参数的简要说明。

纤维强度测试标准

纤维强度测试主要依据国际标准和相关行业标准,包括ASTM、ISO等,纤维强度测试通常采用拉伸强度、断裂强度等指标,用以评估纤维的抗拉性能。

织物抗拉强度测试标准

织物抗拉强度测试主要依据国家标准和行业标准,如GB/T 29198等,织物抗拉强度测试通常采用多种测试方法,包括万能材料试验机、动态拉伸试验机等,用以评估织物的抗拉性能和耐用性。

撕裂强度测试标准

撕裂强度测试主要用于评估织物的耐磨性和抗撕裂性能,撕裂强度测试通常采用撕裂仪或撕裂机进行,根据不同织物材料和性能要求,设定合适的撕裂速度和压力等参数。

纺织品测试力标准案例说明

以下是一个纺织品测试力标准的案例说明,以供参考:

某品牌牛仔布的测试过程

该品牌牛仔布在生产过程中,需要进行多种性能测试,以确保产品的质量和性能符合要求,织物抗拉强度测试是重要的一环,该品牌采用了国际标准和相关行业标准进行测试,同时结合实际生产情况,设定了合适的测试参数和条件,经过多次试验和数据分析,最终得出该牛仔布的抗拉强度符合国家标准要求。

某新型面料的质量检测流程

某新型面料在进入市场前,需要进行全面的质量检测,织物撕裂强度测试是重要的一环,检测机构采用了多种测试方法和技术手段,包括动态拉伸试验机、撕裂仪等,通过对该新型面料的撕裂强度进行测试和分析,得出该面料具有较高的耐磨性和抗撕裂性能,符合市场需求。

纺织品测试力标准的具体标准参数

以下是纺织品测试力的一些具体标准参数:

- 纤维强度测试参数:纤维的拉伸强度、断裂强度等,这些参数可以用于评估纤维的抗拉性能和耐用性。

- 织物抗拉强度测试参数:根据不同的织物类型和性能要求,可以采用不同的测试方法和参数,对于牛仔布,可以采用万能材料试验机进行拉伸强度测试;对于新型面料,可以采用动态拉伸试验机进行撕裂强度测试等。

- 撕裂强度测试案例:根据不同织物材料和性能要求,撕裂强度测试可以设定合适的撕裂速度和压力等参数,对于牛仔布,可以根据不同款式和用途设定合适的撕裂速度和压力值。

总结与展望

纺织品测试力标准是保障纺织品性能和质量的重要手段,在实际应用中,我们应该根据不同纺织品类型和性能要求,选择合适的测试标准和参数,以确保纺织品的质量和性能符合要求,随着科技的不断进步和应用领域的不断扩大,纺织品测试力标准也在不断发展和完善,未来将会更加注重智能化、自动化和数字化等方面的应用和发展。

Articles related to the knowledge points of this article:

Water-Washed Electronic Textiles:A Technical Overview and Case Studies

Navigating the World of Quality Textiles in Tianjin:An Insiders Guide