Preventing Excess Methylene Chloride Formaldehyde)Levels in Textile Goods

: Protecting Textile Goods from Excess Methylene Chloride (CFC-11) and Formaldehyde,Abstract:,The use of methylene chloride (CH2Cl2) for the production of synthetic fibers is widespread, but its environmental implications are a concern. CH2Cl2 is often used as a solvent in textile goods manufacturing processes. However, high levels of CH2Cl2 exposure can lead to health problems, particularly for workers exposed to the gas at work sites. To mitigate this issue and protect workers' health, measures should be taken to minimize the amount of CH2Cl2 used in textile production. One approach is to replace CFC-11 with alternative solvents that have lower ozone depleting potential. Additionally, implementing stricter safety regulations and training programs for textile workers will help to reduce exposure to CH2Cl2. By taking these actions, it is possible to protect textile goods from excess CH2Cl2 levels while maintaining the efficiency of production processes.

Introduction The presence of formaldehyde, a pungent-smelling gas with an unpleasant odor and toxic properties, in textile products can be a major concern due to its health risks. This essay discusses how various methods are employed to ensure that the amount of formaldehyde in textiles does not exceed regulatory limits. The table below provides information on the recommended levels for formaldehyde exposure in different types of textile products.

Recommended Levels for Formaldehyde Exposure in Textile Products | Category | Recommended Level (mg/m3) | |-----------------|-----------------------------------| | Dyed Cotton | 0.1 | | Woolen Dressings | 50 | | Woolens | 5 | | Silks | 250 | | Linens | 40 | | Synthetic Mixed | 50 | | Synthetic | 100 |

Case Study - How Textile Companies Are Managing Formaldehyde Issues In recent years, there has been growing awareness of the need to prevent excessive formaldehyde levels in textiles. One example is the case of a leading textile company in China which faced backlash from consumers and government regulations regarding formaldehyde contamination in its fabrics. The company implemented a comprehensive strategy involving several measures aimed at reducing formaldehyde levels.

The first step was the implementation of stricter quality control standards for raw materials used in the production process, including those that could produce formaldehyde. This involved using more sustainable and environmentally friendly dyes, as well as selecting organic fibers.

Secondly, the company invested in advanced testing facilities that could detect formaldehyde emissions at all stages of production. These tests were carried out regularly to ensure that any potential issues were detected early.

Additionally, the company introduced a new line of products that are certified by international standards, specifically designed to reduce or eliminate formaldehyde emissions. These include breathable clothing made from bamboo and hemp fibers, as well as linens made from organic cotton.

Finally, the company conducted regular education campaigns to inform consumers about the importance of choosing products with low formaldehyde levels, and encouraged them to opt for natural and organic alternatives.

Conclusion Preventing excessive formaldehyde levels in textile goods is essential for maintaining consumer safety and protecting human health. By implementing stringent quality control measures, investing in advanced testing facilities and developing innovative products, textile companies can effectively reduce formaldehyde emissions and comply with regulatory standards. As highlighted through the case study, transparency and education play critical roles in building trust with consumers and ensuring compliance with regulations.

大家好,今天我们来聊聊纺织品如何防止甲醛超标的话题,甲醛是一种常见的化学物质,广泛存在于纺织品中,特别是在一些合成纤维和纺织品中含量较高,为了保护我们的健康和环境,了解如何有效防止甲醛超标至关重要。

纺织品中的甲醛来源

纺织品中的甲醛主要来源于纺织品的加工过程中使用的化学物质,在纺织品的生产过程中,为了增加纤维的强度和弹性,常常需要使用一些化学物质来处理纤维,这些化学物质可能包括甲醛树脂、防皱剂等。

甲醛超标的影响

甲醛超标会对人体健康造成严重危害,长期接触高浓度的甲醛可能导致呼吸道疾病、皮肤过敏等问题,甲醛超标还可能对环境和生态系统造成破坏。

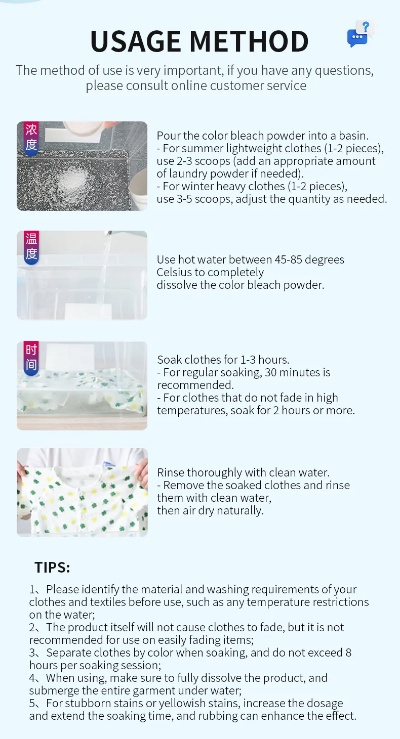

防止甲醛超标的措施

- 选择优质纺织品:在购买纺织品时,应选择有质量保证的品牌和产品,优质纺织品通常采用环保材料,并经过严格的生产工艺控制,可以减少甲醛等有害物质的含量。

- 检测纺织品质量:消费者可以通过查看纺织品上的标识和检测报告来了解纺织品是否符合国家或行业标准,如果发现纺织品甲醛含量超标,可以选择购买经过认证的环保纺织品。

- 使用环保材料:在纺织品的生产过程中,应尽量使用环保材料,减少对环境的污染,可以关注一些环保认证标志,选择符合环保标准的纺织品。

- 使用防甲醛技术:一些纺织品生产厂家已经开始采用防甲醛技术,如纳米技术、活性炭吸附等,来减少纺织品中的甲醛含量,这些技术可以有效吸附和分解甲醛,降低其释放到环境中的风险。

- 案例分析:以某品牌纺织品为例,该品牌采用了环保材料和技术,严格控制生产过程中的甲醛含量,该品牌还定期进行甲醛含量检测,确保产品的质量符合国家标准,该品牌还积极推广环保理念,让消费者了解如何选择环保纺织品。

纺织品是日常生活中不可或缺的物品,但同时也需要我们关注其质量和安全性,防止甲醛超标是保障纺织品质量和安全性的重要措施之一,通过选择优质纺织品、了解纺织品质量、使用环保材料和技术等方法,我们可以有效地防止纺织品中的甲醛含量超标,保护我们的健康和环境,我们也应该关注环保理念,让更多的人了解如何选择环保纺织品。

就是关于纺织品如何防止甲醛超标的简要介绍,在今后的生活中,我们更应该关注纺织品的品质和安全,选择健康、环保的纺织品,为我们的健康和生活质量保驾护航。

Articles related to the knowledge points of this article:

Navigating the World of Fashion Textiles:A Comprehensive Process Map

The Mystery of Textile Waste:A Case Study on Distracting Yarn

The Fabric of Culture:An Exploration into the World of Mian Tong Textiles