Textile Storage Devices:A Comprehensive Guide from Basics to Advanced

This guide provides an in-depth understanding of textile storage devices from basics to advanced concepts. It covers various types, features, and applications of these products, including compressors, dryers, steamers, and ironers. The guide also discusses the importance of maintaining proper storage conditions for textiles to ensure their quality and safety. Additionally, it explores innovative technologies such as smart textile storage systems that can help improve efficiency and reduce costs. Overall, this comprehensive guide is designed to provide textile professionals with a thorough understanding of textile storage devices and how they can be integrated into their operations for optimal performance.

纺织品储存装置的全面指南 - 从基础到高级

In the world of textile production, efficient storage is a critical factor that ensures the integrity and longevity of the fabric, ensuring it remains fresh and ready for use in the market or for further processing. The right storage solution not only protects against damage but also enhances the quality and value of the finished product. Here's a comprehensive overview of the key components of textile storage devices.

Standard Shelving Units

Shelving units are the foundation of most textile storage systems. These include vertical and horizontal rails, shelves, and supports. They can be made from wood, metal, or plastic depending on durability and maintenance requirements. For instance, wooden shelving is ideal for high-quality textiles due to its natural beauty while steel shelving is durable and resistant to corrosion.

Bins and Pallets

For bulk storage, bins and pallets play a crucial role. They allow for easy stacking and transportation of textiles. Plastic and metal bins are popular choices, with plastic offering a low-maintenance alternative to metal. Pallets come in various sizes, shapes, and materials, including wood, metal, and plastic, all designed to optimize space usage and facilitate loading/unloading processes.

Refrigerated Storage

For sensitive or perishable textiles like silk or woolen fabrics, refrigerated storage is essential. This type of storage uses chilled air or refrigeration units to maintain a specific temperature, preventing deterioration over time.

Vacuum Sealers

Vacuum sealers are used to preserve textiles by removing air bubbles and preventing moisture buildup, both of which can lead to fabric degradation. They are especially useful for garments and other delicate items.

Electronic Controlled Environments (ECE)

For specialized applications, ECE systems offer controlled environments for storing textiles at precise temperatures and humidity levels. This is particularly beneficial for the preservation of expensive or sensitive textiles.

Warehouse Management Systems

The success of any textile storage project relies heavily on effective warehouse management systems. These tools help monitor inventory, track movements of goods, and ensure compliance with regulations and best practices.

Inventory Tracking

A well-organized inventory system is vital for maintaining accurate stock levels and managing inventory effectively. RFID tags can be used for quick and accurate tracking of each item’s location and movement.

Automation

Automation has become increasingly important in textile storage as more complex tasks such as sorting, picking, and packing are automated. This not only reduces labor costs but also improves efficiency and accuracy.

Case Study: Cotton Textile Storage in China

Consider a major textile company operating in China, where climate conditions and manufacturing demands demand sophisticated textile storage solutions. The company utilizes a multi-tiered hierarchy of storage facilities, starting with standard shelving units in their warehouses. These are supplemented by custom-made racking systems for larger quantities of textiles and pallets for transporting them across different regions.

The company also employs refrigerated storage for delicate cotton fabrics, utilizing state-of-the-art refrigerated containers and control systems to ensure consistent temperature conditions throughout the storage process. Additionally, they incorporate vacuum sealers to eliminate air bubbles and prevent moth infestations.

Finally, an integrated inventory management system is implemented to monitor every aspect of the textile supply chain, from raw material procurement to finished products' distribution worldwide. This ensures that each step of the production process is optimized for efficiency, reducing waste and maximizing profitability.

Conclusion

Textile storage is a complex process that requires a range of specialized equipment and advanced technology to ensure the integrity and value of the final product. By implementing a combination of standard and specialized storage solutions, companies not only meet regulatory requirements but also optimize their operational efficiencies, ultimately enhancing their competitive edge in the global market.

大家好!今天我们来聊聊纺织品储存装置都包括哪些内容,在储存纺织品时,选择合适的储存装置对于确保其安全、方便和有效存储至关重要,下面我们将通过一个英文案例和表格来详细介绍纺织品储存装置包括哪些方面。

纺织品储存装置概述

纺织品储存装置主要包括以下几种类型:

-

干燥设备:用于去除纺织品表面的水分,防止霉菌生长,干燥设备通常包括吸湿剂、热风循环系统等。

-

分类存储区:用于将纺织品按照不同类型、规格或用途进行分类存储,棉布、丝绸、羊毛等不同材质的纺织品应有专门的存储区域。

-

防尘设备:用于防止纺织品在储存过程中受到尘埃和杂质的影响,采用防尘罩、过滤器等设备。

-

温度和湿度控制设备:用于调节储存环境的温度和湿度,确保纺织品在适宜的环境下储存。

案例说明

假设我们有一个纺织品生产企业的案例,他们需要储存大量的纺织品,以下是该企业的纺织品储存装置的一些具体内容:

案例:某纺织品生产企业

-

干燥设备:该企业使用专业的干燥设备来去除纺织品表面的水分,防止霉菌生长,干燥设备包括高效吸湿剂和热风循环系统,确保纺织品在储存过程中始终保持干燥状态。

-

分类存储区:该企业设有专门的布料存储区域,用于存放棉布、丝绸等不同材质的纺织品,每个区域都有明确的标识和分类标签,方便管理人员进行管理和查找。

-

防尘设备:该企业还配备了专业的防尘罩和过滤器,用于防止纺织品在储存过程中受到尘埃和杂质的影响,这些设备可以有效防止灰尘和杂质进入存储区域,确保纺织品始终处于清洁的环境中。

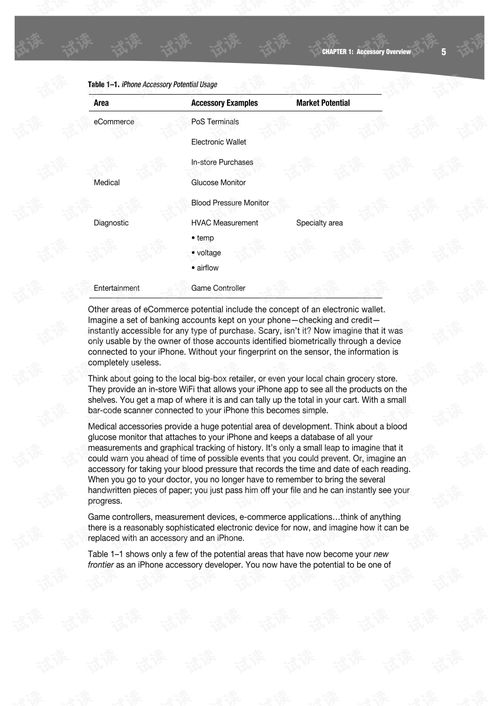

表格补充说明

以下是关于纺织品储存装置的详细表格说明:

| 类别 | 设备或设施 | 描述 | 示例说明 |

|---|---|---|---|

| 干燥设备 | 吸湿剂、热风循环系统 | 用于去除纺织品表面的水分,防止霉菌生长 | 该企业使用的干燥设备包括高效吸湿剂和热风循环系统,确保纺织品始终保持干燥状态 |

| 分类存储区 | 布料存储区域 | 用于存放不同材质的纺织品 | 该企业设有专门的布料存储区域,用于存放棉布、丝绸等不同材质的纺织品 |

| 防尘设备 | 防尘罩、过滤器 | 用于防止纺织品在储存过程中受到尘埃和杂质的影响 | 该企业配备了专业的防尘罩和过滤器,确保纺织品始终处于清洁的环境中 |

| 其他辅助设施 | 其他存储辅助设备 | 如温度和湿度控制设备等 | 该企业还可能配备温度和湿度控制设备,用于调节储存环境的温度和湿度,确保纺织品在适宜的环境下储存 |

纺织品储存装置主要包括干燥设备、分类存储区和防尘设备等设施,在选择和使用纺织品储存装置时,需要考虑多种因素,如材质、用途、环境要求等,通过合理的储存装置配置,可以确保纺织品的安全、方便和有效存储,以上内容仅供参考,如需更多信息,建议查阅相关文献或咨询专业人士。

Articles related to the knowledge points of this article:

The Carbon Content of Textiles

Comprehensive Guide to Fabric Prices in Jiangsu Province

How to Identify Textiles for Authenticity

The Journey of Exquisite Durable Textiles an Insight into 秀力达纺织品