The Manufacturing Strategy for Textiles:A Comprehensive Guide

: Comprehensive Guide to Manufacturing Strategy for Textiles,Abstract: This paper provides a comprehensive guide on the manufacturing strategy for textiles. The first chapter discusses the importance of textiles in our society and their impact on various industries. It also highlights the need for sustainable and eco-friendly production methods. The second chapter focuses on the different types of textiles and their uses, including clothing, bedding, home decor, industrial fabrics, and more. The third chapter examines the manufacturing processes involved in producing these textiles, including spinning, weaving, knitting, and crocheting. It also covers the latest technological advancements in textile manufacturing, such as automation and precision machinery. The fourth chapter explores the challenges faced by textile manufacturers, including raw material sourcing, labor costs, environmental regulations, and market competition. The fifth chapter offers strategies for addressing these challenges, such as investing in research and development to improve production efficiency, adopting sustainable sourcing practices, and developing innovative marketing strategies to differentiate products from competitors. In conclusion, this paper provides valuable insights into the manufacturing strategy for textiles, providing readers with a comprehensive understanding of the industry's complexities and opportunities.

Introduction In the global textile industry, manufacturing strategy plays a pivotal role in shaping competitiveness, profitability, and sustainability. This article aims to provide a comprehensive understanding of the key aspects involved in the production orientation for textiles, including the selection of technologies, sourcing strategies, quality control measures, and environmentally friendly practices. We will also discuss how these components are aligned with the latest trends in the industry to ensure long-term success in the competitive landscape. In this article, we will explore the importance of a strategic approach to textile manufacturing, its potential impact on the industry, and practical recommendations for those seeking to adopt an innovative and sustainable production model.

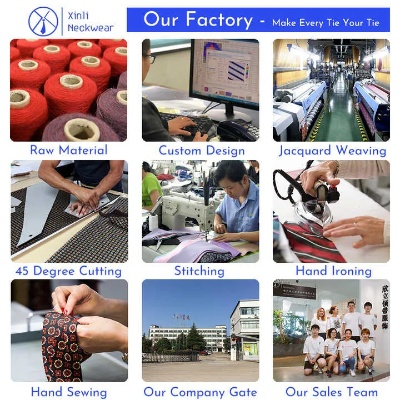

Selecting the Right Technologies Technological advancements have significantly influenced the textile industry's manufacturing strategy. Choosing appropriate technologies is crucial for enhancing productivity, minimizing waste, and maintaining quality standards. Here's a table outlining some of the most commonly used textile technologies:

| Technology | Description | Advantages | Disadvantages |

|---|---|---|---|

| Bubble Dyeing | An ancient dyeing method that produces vibrant colors. | High-quality finishes | Limited color palette |

| Embossing | Creates raised patterns on fabric surfaces. | Enhances texture and visual interest | Can be time-consuming |

| Printing | Includes silkscreen, rotogravure, digital methods. | Provides high precision and speed | May affect fabric structure |

| Weaving | The primary technique for creating woven fabrics. | Versatile and customizable | Can lead to energy consumption |

| Knitting | Uses yarn loops to form a three-dimensional fabric. | Suitable for lightweight, stretchy items | Can be labor-intensive |

Technology Selection Considerations:

- Market Trends: Understand current consumer preferences and market demands.

- Production Capacity: Choose technology suitable for your existing equipment.

- Environmental Impact: Select sustainable and eco-friendly methods.

- Cost-effectiveness: Evaluate the overall cost implications of different technologies.

- Quality Control: Ensure that the selected technology can maintain consistent product quality.

Sourcing Strategies The choice of raw material suppliers significantly influences the production strategy for textiles. Sourcing from reputable and reliable partners ensures the quality of materials, reduces risks associated with supply chain disruptions, and contributes to brand trustworthiness. Some common procurement strategies include:

| Procurement Method | Description | Key Considerations |

|---|---|---|

| Direct Purchase | Purchase directly from manufacturers or factories. | Minimizes middlemen costs, but requires strong relationships with vendors. |

| Wholesale/Retail | Partner with wholesalers or retailers who handle multiple brands. | Can offer lower prices but may compromise on supplier reliability. |

| Contract Manufacturing | Outsource production to a third party based on predefined specifications. | Offers flexibility but might increase costs due to overheads. |

| Joint Ventures | Form partnerships with local businesses to pool resources and knowledge. | Fosters cultural understanding and shared goals but requires careful management. |

Quality Control Mechanisms Quality control measures are essential in ensuring that the finished products meet customer expectations and industry standards. Here’s a list of key quality control mechanisms:

| Quality Control Tool | Description | How It Works |

|---|---|---|

| Inspection Checklist | A systematic checklist for every process step to prevent defects before they emerge. | Helps identify issues early and minimize losses |

| Machinery Maintenance Program | Regularly inspect machinery to detect and fix any issues before production halts. | Prevents downtime and ensures consistent output |

| Quality Audits | Conduct random inspections to verify compliance with standards and regulations. | Ensures transparency and accountability within the organization |

| Training Programs | Impart knowledge on quality control procedures to employees. | Fosters a culture of excellence and continuous improvement |

Environmentally Friendly Practices Sustainability has become an integral part of the textile industry's production strategy. Adopting eco-friendly practices helps reduce carbon footprint, conserve natural resources, and appeal to consumers who seek ethical and responsible products. Some recommended practices include:

| Eco-Friendly Practice | Description | How It Works |

|---|---|---|

| Recycling & Reuse | Repurpose scrap fabrics into new garments or accessories. | Reduced waste and increased resource efficiency |

| Energy-Efficient Production Processes | Use less energy in manufacturing processes. | Lower operational costs and improve environmental performance |

| Green Chemicals and Raw Materials | Choose non-toxic, biodegradable materials and chemicals for production. | Minimize toxic byproducts and promote a healthier work environment |

Conclusion The textile industry's manufacturing strategy is a multifaceted endeavor that encompasses selecting the right technologies, sourcing strategies, quality control measures, and environmentally friendly practices. By aligning these factors with industry trends, companies can not only stay competitive but also build a positive reputation and attract environmentally conscious customers. As the industry continues to evolve, it becomes increasingly important for manufacturers to embrace sustainable practices and incorporate technological advancements into their production processes. By doing so, they can ensure long-term success while contributing to a more sustainable future for our planet.

随着全球经济的快速发展,纺织品生产行业也迎来了新的发展机遇和挑战,为了适应市场需求和行业发展趋势,纺织品生产导向显得尤为重要,本文将围绕纺织品生产导向展开讨论,并通过案例分析进一步阐述其重要性。

纺织品生产导向概述

纺织品生产导向是指企业在纺织品生产过程中,根据市场需求、技术进步、产业政策等因素,制定和实施的一系列策略和措施,其核心目的是提高纺织品的质量、降低成本、提高效率,从而满足消费者日益增长的需求。

案例分析

某地区纺织品生产导向案例

近年来,某地区在纺织品生产方面取得了显著成就,该地区根据市场需求和产业政策,制定了一系列纺织品生产导向措施,该地区加强了技术研发和创新,提高了纺织品的质量和性能,该地区优化了生产流程,提高了生产效率,该地区加强了品牌建设和市场营销,提高了产品的市场竞争力,通过这些措施的实施,该地区的纺织品生产得到了快速发展,成为当地经济的支柱产业。

国内外纺织品生产导向对比

国内外纺织品生产导向存在一定差异,国内纺织品生产企业更加注重技术创新和品牌建设,以提高产品质量和竞争力,国内纺织品生产企业也在不断探索新的生产模式和工艺,以提高生产效率和降低成本,相比之下,国外纺织品生产企业更加注重市场需求和产业政策,通过不断优化生产流程和提高生产效率,来满足消费者日益增长的需求。

纺织品生产导向的具体内容

- 市场需求导向:根据市场需求变化,及时调整产品结构和生产策略,以满足消费者的需求。

- 技术进步导向:加强技术研发和创新,提高纺织品的技术水平和质量。

- 环保导向:注重环保理念,采用环保材料和生产工艺,减少环境污染和资源浪费。

- 绿色发展导向:推动绿色制造和可持续发展,提高企业的社会责任感和可持续发展能力。

- 高效生产导向:优化生产流程,提高生产效率,降低生产成本。

纺织品生产导向的实施策略

- 加强技术研发和创新,提高纺织品的技术水平和质量,企业可以投入更多的资金和人力资源,加强技术研发和创新力度,提高产品的技术含量和附加值。

- 优化生产流程,提高生产效率,企业可以通过引入先进的生产设备和技术手段,优化生产流程,提高生产效率,企业还需要加强员工培训和管理,提高员工的技能水平和综合素质。

- 加强品牌建设和市场营销,提高产品的市场竞争力,企业可以通过加强品牌宣传和推广,提高产品的知名度和美誉度,从而吸引更多的消费者购买,企业还需要加强与供应商和客户的沟通与合作,建立良好的合作关系。

- 推动绿色发展,实现可持续发展,企业可以采取一系列措施来推动绿色发展,例如采用环保材料和生产工艺、开展循环经济等,企业还需要加强与政府和相关机构的合作,共同推动绿色发展。

纺织品生产导向是纺织品行业发展的重要方向,在未来的发展中,企业需要加强技术研发和创新力度、优化生产流程、加强品牌建设和市场营销、推动绿色发展等措施的实施,企业还需要根据市场需求和产业政策的变化,及时调整产品结构和生产策略,以适应市场的变化和发展趋势。

Articles related to the knowledge points of this article:

Exploring the Wonderland of Disney Home Textiles