Summary and Planning of the Textile Factory

This text aims to provide a comprehensive summary and strategic planning for the textile factory's operations. The first section outlines the current state of the facility, highlighting strengths such as advanced machinery and skilled workforce, while also identifying areas for improvement, including inadequate storage facilities and inconsistent supply chain management.,The second part focuses on future goals, setting ambitious objectives for growth, sustainability, and technological advancement. To achieve these objectives, a detailed plan is proposed, which includes implementing a lean production system to optimize resource utilization, adopting sustainable practices to reduce environmental impact, and investing in modern technology to enhance efficiency and productivity. Additionally, a detailed financial plan is included, detailing budget allocations, potential revenue streams, and cost-saving strategies.,Finally, the third section discusses potential challenges and how they can be addressed, such as fluctuations in market demand, labor shortages, and regulatory changes. A contingency plan is also provided to ensure the factory remains resilient in the face of unexpected events or changes.,Overall, this text provides a clear roadmap for the textile factory's operations, outlining both short-term and long-term goals, and offering strategies for addressing potential obstacles.

Introduction The textile industry is a crucial sector in the global economy, providing us with clothing, home furnishings, and various accessories. In this industry, a textile factory plays a vital role in producing these products by utilizing various techniques and processes. Therefore, it is essential for the factory to maintain its efficiency and productivity while also being able to respond quickly to changes in customer demand. This essay aims to provide a summary and planning of the textile factory's operations, highlighting areas that require improvement and suggesting possible strategies for improvement.

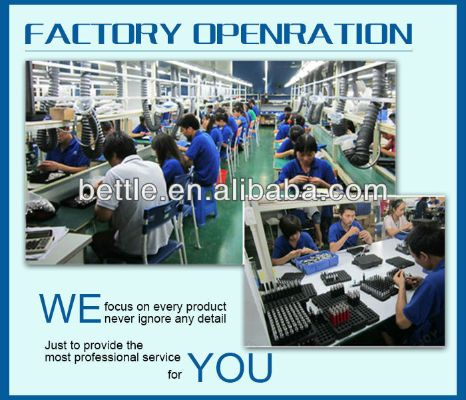

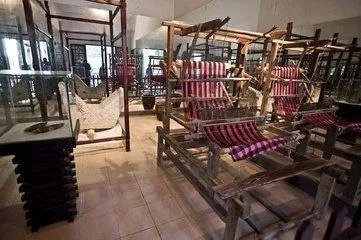

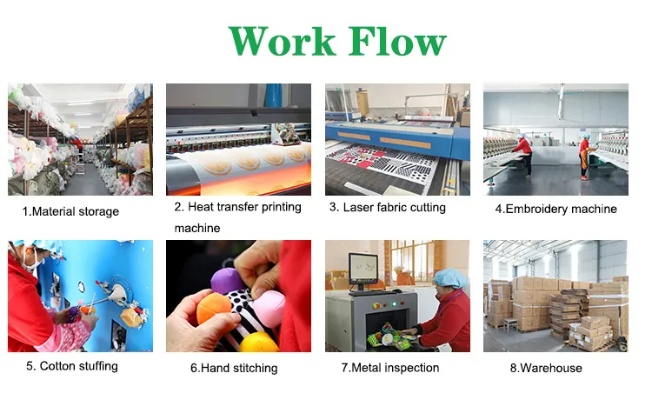

Operational Summary Currently, our textile factory has been operating efficiently with a production capacity of 1 million units per month. The factory utilizes advanced machinery such as knitting machines, weaving machines, and dyeing machines to produce high-quality textile products. We also have a team of skilled workers who are dedicated to ensuring that every product is produced according to our quality standards. Additionally, we have implemented a quality control system that ensures that only defect-free products reach our customers.

However, despite these efforts, there are some areas where we could improve. For example, there is a need to streamline the production process, reduce waste, and increase energy efficiency. Additionally, we need to enhance our communication between departments to ensure that everyone is working towards the same goal.

Planning for the Future To address these challenges, we plan to implement several strategies. Firstly, we will invest in modern machinery and technology to improve our production efficiency and reduce waste. This will include investing in automated machines and robotics that can perform complex tasks without human intervention. Additionally, we will focus on reducing water consumption and waste disposal to reduce our carbon footprint.

Secondly, we will work on enhancing our communication between departments to ensure that everyone is aligned towards the same goal. We believe that effective communication is key to achieving success in any organization, and we will prioritize this aspect by organizing regular meetings and workshops to discuss ideas and share best practices.

Finally, we will continue to improve our quality control system to ensure that all products meet our high standards. We will invest in training our staff members to become proficient in their roles and to identify potential issues early on.

Conclusion In conclusion, the textile industry faces many challenges in terms of efficiency, waste reduction, and communication. However, through implementing modern machinery, technology, and effective communication strategies, we can overcome these challenges and achieve greater success. By focusing on improving our production process, reducing waste, and enhancing communication, we will be well-positioned to meet the needs of our customers and grow our business.

随着全球纺织行业的快速发展,纺织厂作为产业链的重要环节,其生产效率和产品质量对于整个行业的发展至关重要,本次报告旨在总结纺织厂过去一段时间的生产计划,分析存在的问题与挑战,并提出相应的改进措施,结合实际案例,进一步说明纺织厂的生产策略和未来发展方向。

生产概况

-

生产规模与设备情况 本纺织厂现有生产线长度为XX米,拥有先进的生产设备和技术,主要生产各类纺织品,包括棉布、丝绸、化纤等。

-

产品结构与市场需求 根据市场调研,本纺织厂的产品结构以中高端市场为主,同时满足不同客户的需求,市场需求稳定增长,但同时也面临着市场竞争加剧的挑战。

生产计划总结

-

生产目标 本纺织厂的生产目标是在保证产品质量的前提下,提高生产效率,降低生产成本,优化供应链管理,积极拓展国内外市场,提高品牌知名度和市场占有率。

-

生产计划实施情况 在过去一段时间内,纺织厂按照生产计划有序开展生产工作,主要采取了以下措施:优化生产流程,提高设备利用率;加强原材料采购管理,降低采购成本;加强员工培训,提高员工技能水平;加强质量管理,确保产品质量稳定。

-

存在问题与挑战 在生产过程中,纺织厂面临的主要问题包括生产效率不高、成本控制压力大、供应链管理不够完善等,市场竞争加剧也给纺织厂带来了不小的挑战。

案例分析

为了更好地说明纺织厂的生产策略和未来发展方向,我们结合实际案例进行分析。

某纺织厂成功案例 该纺织厂在生产过程中注重技术创新和质量管理,积极引进先进的生产设备和技术,提高生产效率和质量,加强员工培训,提高员工技能水平,通过这些措施,该纺织厂的产品质量得到了显著提升,市场占有率也得到了提高,该纺织厂还积极拓展国内外市场,加强品牌宣传和营销策略,取得了良好的市场效果。

改进措施建议 针对案例中存在的问题和挑战,纺织厂可以采取以下改进措施:优化生产流程,提高设备利用率;加强原材料采购管理,降低采购成本;加强员工绩效考核和激励机制;加强供应链管理,提高供应链的透明度和可靠性,加强技术创新和研发力度,不断提高产品的附加值和竞争力。

改进措施实施计划

为了确保改进措施的有效实施和取得预期效果,纺织厂制定了以下实施计划:

- 优化生产流程,提高设备利用率的具体措施包括:对生产线进行重新布局和优化,提高设备的利用率;加强设备维护和保养,确保设备的正常运行;引入先进的生产管理软件和工具,提高生产效率和产品质量。

- 加强原材料采购管理,降低采购成本的具体措施包括:建立严格的原材料采购管理制度;加强与供应商的合作和谈判能力;采用集中采购和批量采购的方式,降低采购成本。

- 加强员工培训和管理,提高员工技能水平的具体措施包括:定期开展员工培训活动;建立完善的员工绩效考核和激励机制;加强员工的工作环境和福利待遇。

- 加强供应链管理,提高供应链的透明度和可靠性的具体措施包括:建立完善的供应链管理制度;加强与供应商的合作和沟通;引入先进的物流管理系统和工具,提高供应链的透明度和可靠性。

结论与展望

通过本次报告的总结和分析,本纺织厂的生产计划得到了有效的实施和改进,结合实际案例和改进措施的实施计划,展望了纺织厂未来的发展方向和目标。

本纺织厂将继续加强技术创新和研发力度,不断提高产品的附加值和竞争力;积极拓展国内外市场,加强品牌宣传和营销策略;还将进一步加强生产流程的优化和管理,提高生产效率和产品质量;加强员工培训和绩效考核激励机制的建设;还将进一步加强供应链管理,提高供应链的透明度和可靠性。

Articles related to the knowledge points of this article:

The Deployment of Textile Factory Disassembly Diagrams

The Story of Yingxiang Textile Factory