Understanding and Managing Textile Fabric Weight

: Understanding and Managing Textile Fabric Weight,In the realm of textiles, fabric weight is a crucial factor that determines the feel, durability, and overall quality of the garment. This article aims to shed light on the intricacies of managing textile fabric weight while providing practical insights for both professionals and consumers.,To begin with, it is essential to understand the various factors that contribute to the weight of a fabric. These include the fiber content, weave pattern, yarn thickness, and even the manufacturing process used to create the fabric. Each of these elements has an impact on the overall weight and feel of the fabric.,For example, thicker yarns or heavier fabrics will generally result in heavier fabrics with greater weight and softness. Conversely, lighter fabrics are often made from thinner yarns or have a more delicate construction, leading to lightweight but still durable results.,Managing textile weight requires a keen understanding of how these factors interplay. Factors such as the type of yarn, the level of filling, and even the dye process can all influence the fabric's weight and texture.,To ensure optimal results, manufacturers must employ advanced techniques and knowledge of textile science to control the weight and feel of their fabrics. This includes using specialized machinery, adjusting the spinning parameters, and selecting high-quality materials that are both lightweight and durable.,As consumers, understanding the factors that affect textile weight can help us make more informed choices when purchasing clothes and accessories. It is also essential to note that different types of fabrics have varying levels of weight, so it is important to consider the intended use and desired outcome when selecting a fabric.,In conclusion, textile fabric weight is a complex subject that requires a deep understanding of the various factors that influence it. By mastering these principles, individuals can confidently navigate the world of textiles, ensuring that they find the right balance of weight, texture, and durability that suits their needs and preferences.

In the realm of textiles, understanding and managing fabric weight is an important aspect of quality control. Fabric weight is a crucial parameter that determines the texture, durability, and overall appearance of various textile products. This guide will provide insights into what constitutes a "gram per square meter" (gsm) and how to measure it, along with practical tips for managing and interpreting this metric in everyday life.

A gsm is defined as a unit of measurement used to describe the thickness or density of a textile material. It is calculated by multiplying the length of a thread by its width. For example, if a 150-denier thread has a width of 0.03 inches and a length of 4 meters, the gsm would be calculated as follows:

Length of thread (m) * Width of thread (in) / 1000 = GSM (gsm)

Let's take a closer look at the importance of gsm and some practical examples to illustrate its significance:

Importance of Textile Fabric Weight

- Quality Control: High-quality textiles have consistent weights to ensure uniformity in their properties.

- Product Durability: Materials with high gsm are more resistant to wear and tear, making them ideal for outdoor or industrial use.

- Appearance: Different weights affect the aesthetics of textiles. Lighter materials are generally softer but may not last as long, while heavier ones can be more durable but might appear less breathable.

- Economics: Varying gsm can influence the price of a textile product. Lower-weight fabrics often have lower prices but may not be suitable for heavy-duty applications.

Measuring Grams Per Square Meter (Gsm) To measure gsm, one needs to consider both the weight of individual threads and the number of threads per square inch (T/Sq). Here's a simple formula for calculating gsm:

GSM (gsm) = (Number of Threads per Inch * Thickness of Thread in Inches) / 10000

For example, let's assume a 600 denier thread with a width of 0.03 inches and a length of 4 meters. To find the gsm:

Length of thread (m) * Width of thread (in) / 10000 = GSM (gsm)

Now, let’s move on to practical tips and examples:

Practical Tips for Managing Textile Fabric Weight

- Choose Based on Purpose: Different materials are suited for different uses. For instance, cotton is lightweight and breathable, making it ideal for casual clothing; while polyester is thicker and stronger, making it ideal for work clothes and outdoor gear.

- Invest in Quality: Investing in higher-quality materials can save costs in the long run by extending the lifespan of your textile products.

- Consider Durability: If durability is a priority, opt for materials with higher gsm values. However, be aware that lighter materials might offer better breathability, which is important in warm climates.

- Customize Products: Customized textiles are becoming increasingly popular. Tailored fabrics come in varying gsm ranges, allowing for customization in design and functionality without compromising quality or cost.

- Environmental Considerations: When selecting textile materials, consider their environmental impact. Some fabrics, such as organic cotton, have lower carbon footprints than synthetic alternatives.

Practical Examples

Let’s take a closer look at two real-world scenarios where understanding gsm plays a crucial role:

Scenario One: Fashion Designers Designers who specialize in fashion often need to balance style with functionality. For example, a designer might choose to use a fabric with a higher gsm for a jacket but then adjust the pattern to allow for breathability when wearing the jacket during hotter weather. This balance ensures that the garment looks good while also being comfortable to wear.

Scenario Two: Hospital Wear Hospitals require high-quality fabrics that are durable and easy to care for. For example, surgical gowns should be made from materials that are lightweight yet strong enough to handle frequent laundering without deteriorating quickly. By choosing the right gsm, hospitals can ensure their patients receive proper care while minimizing waste.

In conclusion, understanding and managing textile fabric weight is crucial for ensuring quality products that meet specific demands. Whether you're a designer, a fashion enthusiast, or a hospital administrator, understanding gsm can help you make informed decisions that benefit both your brand and those you serve. So, next time you're considering a new textile material, remember to measure its gsm and think about how it fits into your broader strategy.

在纺织品行业中,平方米克重是一个关键的质量指标,它直接影响到产品的外观、舒适度和成本,本篇文章将围绕纺织品平方米克重展开讨论,并通过英文案例说明来深入理解其影响。

纺织品平方米克重的重要性

纺织品平方米克重是指每平方米纺织品的质量或重量,它反映了纺织品的密度和厚度,对于保证产品质量、提高舒适度以及控制成本具有重要意义,在生产过程中,克重的精确控制对于保证产品质量、提高生产效率以及降低成本都具有重要的意义。

影响纺织品平方米克重的因素

- 纤维类型:不同纤维的密度和厚度不同,因此不同纤维类型的纺织品平方米克重也会有所不同。

- 纱线密度:纱线的密度决定了纺织品的厚度和密度,是影响平方米克重的关键因素之一。

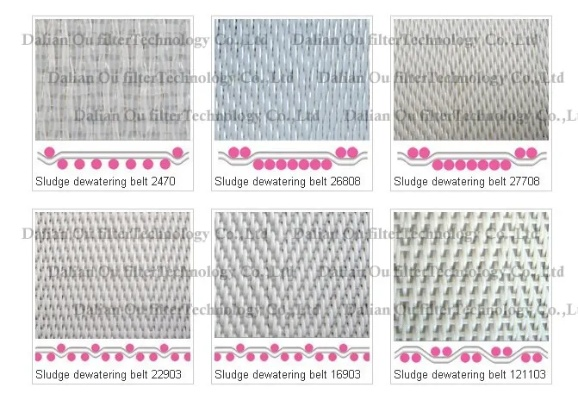

- 织造工艺:不同的织造工艺也会影响纺织品平方米克重,例如平纹织造、斜纹织造等。

- 染整工艺:染整工艺对于纺织品平方米克重也有重要影响,不同的染整工艺可以改变纺织品的外观和手感。

英文案例说明

以某知名品牌的一款纺织品为例,其平方米克重在不同纤维类型、纱线密度和织造工艺下的表现如下:

- 纤维类型:该品牌使用不同纤维类型的纺织品,如纯棉、涤纶等,其平方米克重差异明显,纯棉纺织品通常具有较高的柔软度和舒适度,而涤纶纺织品则具有较高的强度和耐磨性。

- 纱线密度:该品牌采用不同的纱线密度进行织造,例如高密度的平纹织造和低密度的斜纹织造,高密度平纹织造的纺织品具有较高的厚度和密度,手感更加细腻;而低密度斜纹织造的纺织品则具有较好的透气性和舒适度。

- 织造工艺:该品牌采用先进的织造工艺进行生产,例如采用先进的机器设备和自动化生产线,提高了生产效率和产品质量,该品牌还注重环保和可持续性,采用环保染整工艺,降低了生产成本和环境影响。

影响因素分析

- 纤维类型:不同纤维的密度和厚度不同,因此需要根据具体需求选择合适的纤维类型,还需要注意纤维的环保性和可持续性,避免对环境造成不良影响。

- 纱线密度:纱线的密度是影响纺织品平方米克重的关键因素之一,在织造过程中需要严格控制纱线的质量和长度,以确保织物的厚度和密度符合要求,还需要注意纱线的均匀性和一致性,以提高织物的质量和外观效果。

- 织造工艺:不同的织造工艺可以改变纺织品的外观和手感,在生产过程中需要注重工艺的优化和创新,提高生产效率和产品质量,还需要注重环保和可持续性,降低生产成本和环境影响。

纺织品平方米克重是衡量纺织品质量的重要指标之一,它直接影响到产品的外观、舒适度和成本,在生产过程中需要严格控制纤维类型、纱线密度和织造工艺等关键因素,以提高纺织品的质量和性能,还需要注重环保和可持续性,降低生产成本和环境影响。

Articles related to the knowledge points of this article:

Understanding and Applying Textile Color Standards

The Complete Guide to Textile Dyeing Methods

UV Resistant Textile Manufacturing

Exploring the Market for Sustainable Textile Recycling in Fuzhou

Limitations in the Collection of Waste Textiles:A Call to Action