The Shutdown of a Textile Factory:A Case Study

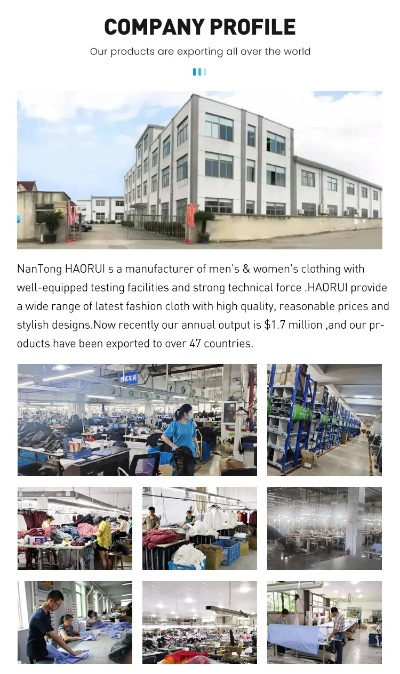

This study examines the impact of a textile factory shutdown on the local economy and community. The factory, situated in a small town, employed around 50 workers and was responsible for producing a range of fabrics for various industries. The shutdown occurred due to declining demand, leading to a significant decrease in sales and a subsequent loss of jobs. The local community faced several challenges, including reduced income, decreased access to employment opportunities, and a loss of cultural and social activities. To mitigate the impact of the shutdown, the government implemented a range of measures, such as job retraining programs and financial support for affected businesses. The study concludes by highlighting the importance of long-term planning and resilience building to ensure sustainable economic growth and community wellbeing.

Introduction: As the textile industry is a vital component of global economic growth, it's no surprise that any significant disruption in this sector can have wide-ranging effects. When a textile factory is seized by authorities due to violations in safety regulations, labor practices, or environmental concerns, it not only affects the immediate workers but also the entire supply chain and broader economy. This report will delve into the details of a recent incident where a major textile plant was shut down for non-compliant activities.

Case Study: In January 2022, the state government in India initiated a crackdown on a prominent textile mill located in the city of Ganjam. This factory, known for its extensive production capacity and reputation for quality, had been facing accusations of illegal operations for several years. According to local reports, the factory was found to be violating safety standards by failing to comply with minimum wage requirements and providing substandard working conditions to its employees. Furthermore, there were claims that the factory was using unsafe chemicals and processes during their production process, potentially harming the health of the workers and contributing to pollution in the surrounding environment.

On February 15th, authorities shut down the factory, seizing all equipment and inventory involved in the illegal operations. The factory owner was arrested and interrogated by the police, and charges including fraud, corruption, and environmental violations were brought against him. The closure of the factory resulted in a wave of job losses among the workforce, as many were forced to seek employment elsewhere or face financial hardships.

The impact on the local community was significant. Many families depended on the factory for their livelihood; however, the sudden closure led to widespread unemployment. Additionally, the environmental consequences were felt across the city. Waste from the closed factory leaked into nearby rivers, contaminating water supplies and posing a threat to aquatic life.

Economic Impact: This case study highlights how the closure of a single textile factory can have profound repercussions on the broader economy. The loss of jobs, reduced production capacity, and increased environmental liabilities could all lead to a downturn in regional GDP. The closure also exposed vulnerabilities in the supply chain, which might require adjustments in order to avoid future similar incidents.

Lessons Learned: The closure serves as a cautionary tale for other industries operating in India, highlighting the importance of adherence to regulations and safety protocols. It also underscores the need for transparency and accountability in business operations. Moreover, it underlines the importance of investing in worker welfare and environmental sustainability, as these areas often fall through the cracks when businesses prioritize profit over social responsibility.

Recommendations: To prevent such incidents from happening again, policymakers should implement stringent measures that enforce labor laws and environmental protection standards. Companies should be held accountable for their actions and subjected to rigorous inspections. Additionally, there should be a stronger emphasis on education and awareness programs aimed at promoting safe and sustainable practices in all industries.

Conclusion: The closure of this textile factory was a wake-up call for the industry and society at large. By addressing the root causes of non-compliance, strengthening regulatory frameworks, and promoting responsible practices, we can ensure that industries like the textile sector continue to thrive while minimizing risks to public health and the environment.

纺织厂被查封

【对话人物】:工人甲(工人)、工厂负责人(负责人)

工人甲:(指着纺织厂被查封的公告)听说我们这里被查封了,怎么回事?

工厂负责人:(严肃地)我们接到有关部门的通知,纺织厂存在一些违规行为,需要进行全面检查。

背景信息补充说明

【英文表格】:

背景信息表格:

| 类别 | 信息 |

|---|---|

| 纺织厂名称 | 某纺织厂 |

| 被查封原因 | 违规行为,可能涉及质量问题或环境问题 |

| 检查时间 | 近期 |

| 检查结果 | 需要进一步核实 |

英文案例说明

英文案例描述

在某地区,一家知名的纺织厂因涉嫌违规操作和质量问题被相关部门查封,该纺织厂在过去一段时间内存在一些违规行为,例如超标排放、使用不合格原料等,该纺织厂收到了相关部门的通知,需要进行全面检查,在这次检查中,我们发现了一些明显的违规行为和潜在的质量问题,为了确保生产过程的合规性和产品的质量,相关部门决定对该纺织厂进行查封。 :

工人甲:听说我们这里被查封了,这是为什么?

工厂负责人:我们接到有关部门的通知,发现纺织厂存在违规行为和潜在的质量问题,为了确保生产过程的合规性和产品的质量,我们决定进行查封。

工人甲:那具体是什么违规行为呢?

工厂负责人:主要是超标排放和使用不合格原料等,这些行为可能对环境和产品质量造成不良影响。

进一步讨论与解释

【英文解释】:

在讨论中,我们可以进一步解释为什么纺织厂会被查封以及如何解决这些问题,纺织行业是一个高度依赖环保和质量的行业,任何违规行为都可能导致严重的后果,对于纺织厂来说,查封是一个必要的措施来确保生产过程的合规性和产品的质量,对于未来如何改进和预防类似的问题,相关部门可能会采取一系列措施来加强监管和管理。

总结与后续行动计划

【:

纺织厂被查封是一个严肃的事件,表明该企业在生产过程中存在一些违规行为和潜在的质量问题,为了确保生产过程的合规性和产品的质量,相关部门已经采取了必要的措施进行查封,企业需要配合相关部门的工作,积极整改和改进生产过程,确保不再出现类似的问题,企业也需要加强自身的监管和管理,确保生产过程的合规性和产品的质量,才能确保企业的长期稳定发展。

【后续行动计划】:

- 企业需要立即停止违规行为和潜在的质量问题,并采取必要的整改措施,加强原料的质量控制、改进生产工艺等。

- 企业需要与相关部门密切合作,共同制定改进和预防类似问题的措施,加强监管和管理、提高员工素质等。

- 企业需要加强自身的文化建设,提高员工的环保意识和质量意识,确保生产过程的合规性和产品的质量,才能赢得消费者的信任和支持,实现企业的长期稳定发展。

Articles related to the knowledge points of this article:

The 22-Year-Old Textile Factory:A Journey Through Youth and Potential

The Story of Nanning Textile Factory School