The Role of Textile DBP in Environmental Protection and Health

In recent years, with the rapid development of textile industry, environmental protection and health have become hot topics. Textile DBP (Dye-Bath Process) is one of the important dyeing processes in textile industry. The main pollution sources of DBP are dye bath, auxiliary chemicals and wastewater, and the main treatment technologies include physical methods, chemical methods and biological methods. The paper summarizes the current situation and research progress about DBP and its treatment technology, and puts forward the future research trends and directions.

In today's world, the importance of protecting our environment and ensuring human health cannot be overstated. One area where we can see the impact of environmental concerns is in the production and use of textiles. In recent years, there has been increasing awareness of the potential harmful effects of certain chemicals, including Dibutyl Phthalate (DBP), which is commonly used as a plasticizer in many types of plastics, including those in textiles. This article will explore the role of textile DBP testing in environmental protection and health.

Textile DBP testing involves analyzing the levels of DBP in textile products to determine their safety and potential risks for human health. This testing is essential because textiles are often exposed to various chemicals during their manufacturing process, and some of these chemicals may have harmful effects on human health if ingested or come into contact with the skin.

To understand how textile DBP testing works, it's helpful to consider an example of a common textile product that contains DBP - polyester fabric. Polyester is a popular synthetic fiber that is widely used in clothing, upholstery, and other textile products. However, it's worth noting that polyester fabrics can contain DBP, which can potentially pose health risks if not properly managed.

The first step in conducting textile DBP testing is to collect samples of the fabric. These samples should be representative of the entire batch of fabric being tested, so they must be collected from different areas of the fabric and from different batches. Once the samples have been collected, they can be sent to a laboratory for analysis.

The next step in textile DBP testing is to analyze the samples for DBP levels. This can be done using various methods, including gas chromatography (GC) and liquid chromatography (LC). These methods allow researchers to identify specific compounds present in the samples and quantify them.

Once the samples have been analyzed, the results can be compared to established standards or guidelines to determine whether they meet regulatory requirements. If the DBP levels are above acceptable limits, further investigations may be required to determine the source of the contamination and develop strategies to reduce exposure to the chemical.

The results of textile DBP testing are critical for ensuring safe and healthy use of textile products. For example, if a particular brand of polyester fabric was found to contain high levels of DBP, manufacturers may need to take action to reduce the levels of DBP in their products or implement additional measures to protect consumers and the environment.

One important consideration when conducting textile DBP testing is the potential for cross-contamination between different types of textiles. This is because many chemicals used in the manufacturing process are often used in a variety of applications, including clothing and upholstery. Therefore, it's crucial to test all types of textiles for DBP levels to ensure that they are safe for human and ecological use.

Another important factor to consider when conducting textile DBP testing is the long-term exposure to DBP. While acute exposure to high levels of DBP can cause harm to humans, chronic exposure may have more significant effects on health. Therefore, it's important to consider both short-term and long-term exposure when assessing the risk associated with textiles containing DBP.

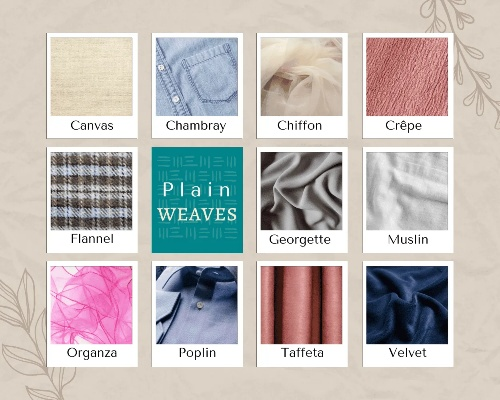

In addition to testing for DBP levels, it's also important to consider other factors such as colorfastness, flame resistance, and biodegradability. These attributes are important for ensuring that textile products are not only safe but also sustainable and eco-friendly. By considering these factors, manufacturers can create more durable, efficient, and environmentally friendly textile products.

In conclusion, textile DBP testing plays an important role in ensuring that textile products are safe for human use and do not contribute to environmental pollution. By following proper testing procedures and regulations, manufacturers can minimize the risks associated with using textile products and promote sustainable production practices. It's important for consumers, manufacturers, and policymakers to work together to develop effective strategies for reducing DBP levels in textile products and promoting environmental stewardship.

大家好,今天我们将讨论纺织品中双酚A测试的重要性及其在实际应用中的具体操作,双酚A是一种常见的有机化合物,广泛应用于塑料、涂料、纤维等工业领域,对纺织品中双酚A的测试结果至关重要,以确保产品的质量和安全性。

双酚A测试方法

- 标准方法:根据相关国家标准,纺织品中双酚A的测试通常包括以下步骤:样品准备、标准溶液配制、样品测试、数据记录和分析。

- 案例分析:为了更好地理解双酚A测试的实际操作,我们以一个具体的案例为例进行说明,某品牌的新纺织品在生产过程中使用了双酚A作为关键成分,为了确保产品的质量和安全性,该品牌进行了严格的双酚A测试。

纺织品双酚A测试过程

- 样品准备:从供应商处获取待测试的纺织品样品,样品应符合相关标准和规定。

- 标准溶液配制:根据国家标准和测试要求,配制适量的双酚A标准溶液。

- 样品测试:将配制好的标准溶液涂抹在纺织品样品上,进行相应的测试,这一步骤通常包括接触角测试、溶解性测试等。

- 数据记录与分析:记录测试结果,分析数据,得出结论。

案例说明

假设某品牌的新纺织品在生产过程中使用了大量的双酚A作为关键成分,为了确保产品的质量和安全性,该品牌进行了严格的双酚A测试,以下是具体的测试过程和结果:

- 样品准备:从供应商处获取待测试的纺织品样品,并进行必要的清洁和处理。

- 标准溶液配制:根据国家标准和测试要求,配制适量的双酚A标准溶液,这一步骤需要精确控制溶液的浓度和纯度。

- 接触角测试:通过使用专业的接触角测试仪,对纺织品样品进行接触角测试,这一步骤可以评估双酚A对纺织品性能的影响,以及其在纺织品中的分散性和稳定性。

- 溶解性测试:通过一系列的实验和测试,评估双酚A在纺织品中的溶解性和稳定性,通过溶解性试验来检测纺织品在特定溶剂中的溶解性能。

- 结果分析:根据测试结果,得出结论,如果纺织品中双酚A的含量超标或存在其他问题,该品牌将采取相应的措施进行整改,该品牌也将根据国家标准和测试要求,对供应商进行严格的监管和质量控制。

纺织品双酚A测试是确保产品质量和安全性的重要环节,通过严格的双酚A测试,可以确保纺织品符合相关标准和规定,从而保证产品的质量和安全性,在实际应用中,我们应该重视纺织品双酚A测试的重要性,并采取相应的措施进行质量控制和管理,我们也应该加强相关标准和规定的制定和更新,以适应不断变化的市场需求和技术发展。

Articles related to the knowledge points of this article:

Stylish and Versatile Customized Textile Apron Designs for Every Occasion