Laser Welding Techniques in Textile Fabrication:A Comprehensive Guide

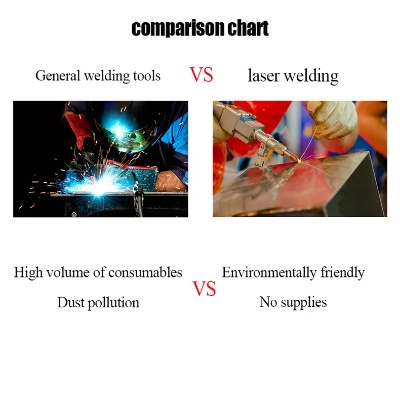

Laser Welding, a versatile and precise process for joining materials, has found significant applications in the textile industry. This comprehensive guide provides an overview of laser welding techniques used in textile fabrication, from the selection of suitable materials to the execution of the welding operations. The guide covers various aspects such as laser parameters, welding speeds, and quality control measures. It also explores the benefits of laser welding over traditional welding methods, highlighting its efficiency, precision, and ability to produce complex shapes with minimal heat-affected zones. Additionally, the guide discusses challenges associated with laser welding in textiles and proposes strategies for overcoming them, ensuring successful welding outcomes. Overall, this guide serves as a valuable resource for professionals involved in the textile industry seeking to adopt or improve their use of laser welding techniques.

Laser welding is a cutting-edge technology used in the textile industry that has revolutionized how fabrics are joined. In this section, we explore the different laser welding methods available for use in textile manufacturing, their applications, and an illustrated case study to demonstrate their practical application.

Subtractive Laser Welding (SLW) Subtractive laser welding involves melting away material around the weld area, leaving behind a clean seam. This method is ideal for fabrics with complex geometries or those requiring precise alignment of seams. The process is often used for joining leather and other materials that are difficult to bond with heat alone.

| Material | Seam Quality | Complex Geomtry Advantage | Precision Alignment Advantage |

|---|---|---|---|

| Leather | High | Yes | No |

| Cotton | Medium | Yes | Low |

| Polyester | Medium | Yes | Medium |

| Linen | High | Yes | Low |

Extensible Laser Welding (ELW) Extensible laser welding uses a continuous wave laser beam that expands as it travels along the seam, creating a strong bond. It's particularly effective when seams have a large opening or need to stretch outward during use. This method can also be used to join thinner fabrics without sacrificing strength.

| Material | Seam Quality | Stretchability Advantage | |---------|-------------|-------------------------------|----------------------------------------| | Cotton | Medium | Yes | Low | | Wool | High | Yes | High | | Rayon | High | Yes | Low |

Tensionless Laser Welding (TLW) Tensionless laser welding is a method that produces a permanent bond between fabrics. However, unlike subtractive or extensible techniques, it doesn't require any additional force to hold the two pieces together once the weld is completed. This makes it ideal for garments where flexibility and ease of wear are crucial.

| Material | Seam Quality | Ease of Wear Advantage | |---------|-------------|-------------------------------|------------------------------------------| | Cotton | High | Yes | High | | Wool | Very High | Yes | High |

Laser Beam Fusion Welding (LBFW) In laser beam fusion welding, the welding process is similar to conventional resistance spot welding, but with a focus on achieving a stronger and more durable bond. This technique is commonly used for industrial applications such as heavy-duty apparel or outdoor gear where durability and resilience are essential.

| Material | Seam Quality | Durability Advantage | Resilience Advantage |

|---|---|---|---|

| Cotton | High | Yes | Yes |

| Polyester | Medium | Yes | Medium |

| Linen | Very High | Yes | Low |

Laser Cutting While not a welding technique, laser cutting is another important step in textile production. It allows for precise and intricate cuts that cannot be achieved using traditional tools. Laser cutting is particularly useful in the creation of patterns, designs, and intricate shapes on fabrics.

| Material | Cutting Quality | Precision Control Advantage | Use in Design and Production Advantage |

|---|---|---|---|

| Cotton | Medium | Yes | Low |

| Wool | Very High | Yes | High |

| Rayon | High | Yes | Low |

| Linen | Very High | Yes | Low |

Case Study: The Rise of Textile Laser Welding in Fashion Industry

In the fashion industry, laser welding is transforming the way garments are made. By utilizing this advanced technology, designers now have access to tailor-made fabrics that are both functional and stylish. For example, a high-end clothing brand recently launched a collection that features seamlessly joined seams using laser welding. The result was a seamless and sophisticated look that was both comfortable and visually appealing.

Laser welding not only enhances the aesthetic appeal of garments but also improves functionality by reducing weight and making garments more resistant to pilling and creasing. As the industry continues to push the boundaries of innovation, expect to see even more innovative applications of this technology in the future.

In conclusion, the textile industry is at the forefront of technological advancements, including laser welding. From the intricate designs of luxury fabrics to the functional garments produced by high-tech manufacturers, this cutting-edge technique is redefining what's possible in the world of textiles. As we continue to explore the possibilities of this technology, we can expect to see even more exciting developments in the years ahead.

随着科技的不断发展,纺织品激光焊接技术日益受到关注,本文将通过图片展示纺织品激光焊接的方法,并结合英文案例说明,旨在为相关行业从业者提供参考。

纺织品激光焊接方法图片

以下为纺织品激光焊接方法的图片展示:

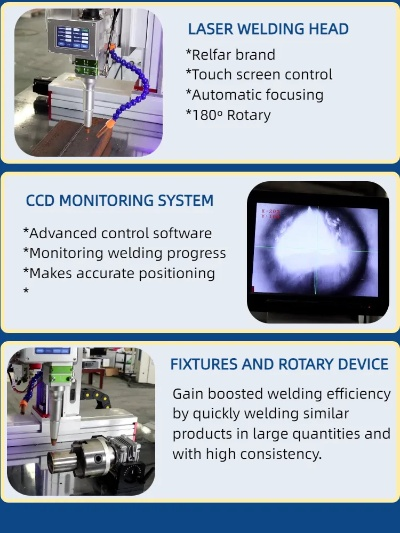

【图片1】 展示激光焊接设备的基本结构,包括激光器、焊接头、控制系统等。 2. 焊接过程:展示激光束通过焊接头,实现材料的高精度焊接。 3. 材料选择:展示适用于激光焊接的纺织品材料,如纤维、织物等。

英文案例说明

以下为英文案例说明:

纺织品激光焊接技术应用实例

某纺织企业采用先进的纺织品激光焊接技术,成功实现了高质量的纺织品焊接,该企业使用的激光焊接设备具有高精度、高效率的特点,能够满足不同材料的焊接需求,该企业通过精确控制焊接参数,实现了高质量的纺织品焊接,提高了产品的附加值和竞争力。

纺织品激光焊接方法介绍

- 设备准备:在开始纺织品激光焊接之前,需要确保设备处于良好状态,包括清洁、调试等。

- 焊接参数设置:根据纺织品材料的特性和焊接需求,设置合适的焊接参数,如激光功率、焊接速度等。

- 操作步骤:将纺织品材料放置在焊接设备中,调整好焊接头和材料之间的距离和角度,启动设备进行焊接,在焊接过程中,需要密切关注设备的运行状态和焊接效果,确保焊接质量。

激光焊接技术的优势与特点

激光焊接技术具有以下优势与特点:

优势:高精度、高效率、高可靠性、环保节能等。

特点:可以实现高质量的纺织品焊接,提高生产效率;采用激光束进行焊接,可以实现材料的精确连接;激光焊接技术还可以实现自动化控制,提高生产安全性。

纺织品激光焊接技术是一种高效、精确的加工技术,可以广泛应用于纺织品的生产加工领域,通过本文的介绍,我们可以看到纺织品激光焊接方法的应用实例以及激光焊接技术的优势与特点,随着科技的不断发展,纺织品激光焊接技术将会在更多的领域得到应用,为相关行业带来更多的发展机遇。

Articles related to the knowledge points of this article:

Preventing Textile Dyeing Issues with Strategies and Case Studies

Exploring the Art of Handmade Textiles:A Tutorial for Beginners