装衣服融成纺织品

"The integration of garments into textile products is an innovative process that involves transforming the fabric and structure of clothing into a seamless, cohesive piece of textile material. This process involves the fusion of different fabrics and materials to create a new form of clothing that is both functional and aesthetically pleasing. The techniques used for this integration can vary depending on the desired outcome and the materials involved. One common method is the use of weaving or knitting techniques to combine multiple layers of fabric together, creating a textured, multi-layered surface. Another technique is the use of embroidery or applique, which adds intricate details and patterns to the fabric surface. The result of these processes is a unique and versatile piece of textile that can be worn in various settings and occasions.": The Transformative Journey of Textiles: From Raw Material to Flawless Fashion

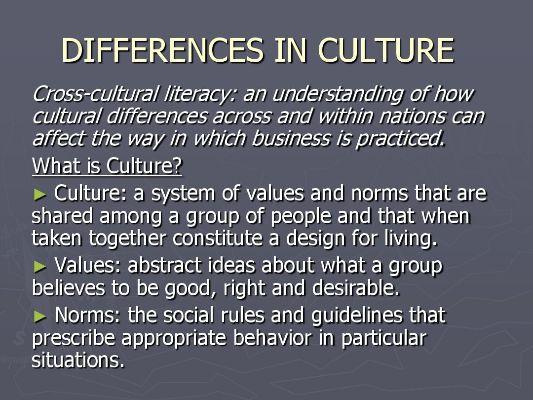

In the realm of textiles, a transformation from raw materials to fashionable garments is an intriguing journey that embodies the essence of creativity and innovation. It's a process where fabrics, often seen as mere substances, are transformed into something more – a form of expression that speaks volumes about human ingenuity and artistic vision. This transformation is not just a matter of crafting but a profound process that reflects our understanding of beauty, functionality, and comfort. In this essay, we will delve into the transformative process of textiles and explore how they become integral parts of our lives.

Textiles have a long and fascinating history that dates back to ancient civilizations such as the Egyptians, who used linen to create clothes for their bodies. However, it wasn't until the Industrial Revolution that textiles truly began to take on a life of their own, thanks to the development of machinery that allowed for the mass production of fabrics. This era ushered in the age of factories, where machines churned out countless pieces of clothing, each one tailored to specific needs and tastes.

Today, textiles continue to evolve at a breakneck pace, driven by advancements in technology and design thinking. Today, we witness the emergence of sustainable textiles, which aim to minimize the environmental impact of their production while still delivering high-quality products. Sustainability is no longer just a buzzword; it has become a guiding principle for manufacturers worldwide, driving the creation of eco-friendly fabrics like organic cotton, bamboo, and recycled polyester.

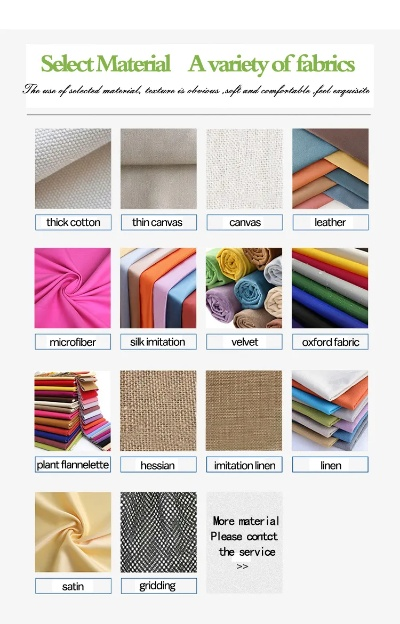

The process of creating textiles can be broken down into several stages, each with its unique set of challenges and solutions. The first stage involves selecting the appropriate raw materials. These materials must meet certain criteria, including being durable, soft, breathable, and resistant to wear and tear. For example, when choosing fabrics for outdoor wear, waterproof properties are paramount, while those looking for cozy layers may prioritize thermal properties.

Once the raw materials are selected, they are then processed into fibers. This stage involves various techniques such as twisting, carding, and spinning, depending on the type of textile desired. The resultant fibers are then woven, knitted, or crocheted into yarns, which form the basis of most fabrics.

The next stage in textile production involves dyeing and finishing the fabric. Dyers use a variety of methods to achieve vibrant colors, including natural dyes extracted from plants, minerals, and other sources, as well as synthetic dyes made from chemicals. Finishing processes include pressing, steaming, and finishing treatments that enhance the texture, durability, and appearance of the fabric.

Finally, once all these steps have been completed, the final product – the textile – is ready to be sold to retailers or directly to consumers. The retail industry plays a crucial role in this chain, ensuring that the textiles reach the right hands and in the right quantities. Retailers, both online and offline, play a vital role in connecting consumers with designers, manufacturers, and brands. They curate collections, host events, and showcase new designs on their platforms, helping to drive sales and foster brand loyalty.

One of the most remarkable examples of textile innovation is the rise of fashion-forward brands like Patagonia. Founded in 1973 by Yvon Chouinard, the brand has revolutionized the way people dress for outdoor activities. Patagonia's commitment to sustainability is evident in every aspect of its operations – from sourcing eco-friendly materials like organic cotton and wool, to designing functional clothing that lasts through multiple seasons. Their approach to textile production mirrors their philosophy: creating clothing that is not only aesthetically pleasing but also environmentally responsible.

Another example is the rise of sustainable denim brands like Everlane, which has disrupted traditional denim manufacturing practices. Instead of relying on mass-produced jeans that are quickly worn out, Everlane partners with small-scale mills in developing countries that adhere to ethical and sustainable production methods. This partnership model ensures that the brand can offer affordable denim options that are still of high quality and ethically sourced.

In conclusion, textiles represent a multifaceted journey that combines creativity, technology, tradition, and sustainability. By exploring different stages of textile production, we can gain a deeper understanding of how these humble materials are transformed into beautiful garments that resonate with our sense of style and our commitment to preserving the planet. From sustainable fabrics to innovative design concepts, textiles continue to push boundaries and inspire us to think outside the box, making them an integral part of our everyday lives.

在日常生活中,我们常常会遇到将衣物进行改造或重新利用的情况,我们就以装衣服融成纺织品为主题,探讨这一过程及其背后的文化意义和实际应用。

衣物改造与纺织品制作过程

衣物改造的步骤

在衣物改造过程中,首先需要将衣物进行清洗和整理,去除多余的材料和污渍,根据需要改造的纺织品类型(如棉质衣物、丝绸衣物等),选择合适的材料进行裁剪和缝制,通过一系列工艺处理,将衣物改造为所需的纺织品。

纺织品制作的流程

纺织品制作通常包括以下几个步骤:原料选择、裁剪、缝制、织造、整理和染色,在织造过程中,可以使用各种织造技术,如平纹织造、斜纹织造、提花织造等,以实现不同纹理和图案的纺织品,还可以根据需要添加功能性材料,如防菌、防污等特殊材料。

案例分析

以一个具体的案例来说明装衣服融成纺织品的过程:

旧衣物改造为家居装饰品

假设有一位家庭主妇,她有一堆旧衣物,想要将这些衣物改造为家居装饰品,她首先对衣物进行清洗和整理,去除多余的材料和污渍,根据旧衣物的材质和特点,选择合适的材料进行裁剪和缝制,通过织造技术,将旧衣物改造为漂亮的窗帘布、抱枕垫等家居装饰品,这些装饰品不仅美观实用,还能传承家庭的历史和文化。

纺织品特点与应用场景

纺织品特点

纺织品具有多种特点,如环保、耐用、美观等,在衣物改造过程中,可以根据需要添加功能性材料,如防菌、防污等特殊材料,以满足不同场合的需求,纺织品还可以根据不同的纹理和图案进行设计和定制,以满足不同消费者的需求。

应用场景

纺织品的应用场景非常广泛,在家庭装饰方面,纺织品可以用于制作窗帘、抱枕垫等家居装饰品,为家庭增添美观和舒适感,在服装领域,纺织品也可以用于制作服装配件、家居服等,纺织品还可以用于制作工艺品、礼品等。

总结与展望

通过以上讨论,我们可以看到装衣服融成纺织品的过程不仅是一种文化传承的方式,也是一种环保、可持续的生活方式,在未来的生活中,随着人们对环保和可持续发展的重视度不断提高,装衣服融成纺织品的应用前景将会更加广阔,随着技术的不断发展,纺织品制作工艺和材料也会不断升级和完善,为人们带来更加优质、美观的纺织品产品。

Articles related to the knowledge points of this article:

The Art of Textiles:A Visual Journey through the World of Fashion