The Transformative Journey of Tianjin Textile Fibers Processing Plant

: The Transformative Journey of Tianjin Textile Fibers Processing Plant,Abstract: This study delves into the transformative journey of the Tianjin Textile Fibers Processing Plant, a pivotal facility for the production and processing of textile fibers. Through a comprehensive analysis of its historical evolution, technological advancements, and strategic transformation strategies, the paper elucidates how this plant has undergone a profound transformation to become a leading player in the global textile industry. By examining its innovative approaches to sustainable practices, its commitment to quality control and customer satisfaction, and its strategic partnerships with international partners, the study highlights the importance of continuous learning and adaptation in maintaining competitiveness in today's dynamic business landscape. Overall, this research provides valuable insights into the transformative journey of a key industrial facility, highlighting the significance of continuous innovation and strategic planning in achieving long-term success.

Introduction: In the tapestry of China's textile industry, Tianjin Textile Fibers Processing Plant stands as a beacon of innovation and efficiency. This plant has not only transformed but also revolutionized the production methods for high-quality textile fibers, making a significant impact on global textile markets. Let's delve into the fascinating journey of Tianjin Textile Fibers Processing Plant and explore how they have achieved such remarkable success.

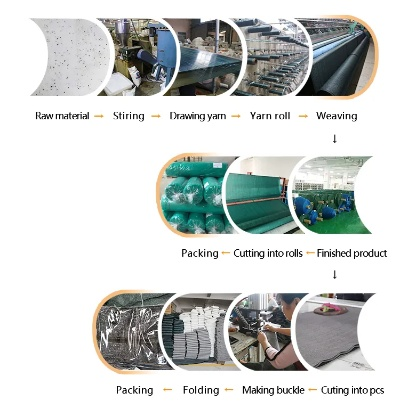

Production Process: At the heart of Tianjin Textile Fibers Processing Plant lies a meticulously orchestrated production process that ensures the highest quality standards in textile fibers. Here are some key steps:

-

Raw Material Selection: Starting with top-grade cotton or synthetic fabrics, the raw materials undergo rigorous testing to ensure they meet stringent quality requirements.

-

Preparation: The raw material is washed, dried, and processed to remove any impurities, ensuring optimal performance during the spinning process.

-

Spinning: Using state-of-the-art spinning equipment, the prepared material is spun into threads. The spinning process involves several stages, from wet spinning to dry spinning, where the thread is further processed to achieve the right diameter and texture.

-

Weaving/Knitting/Pull-Up: Once the thread reaches the desired size and quality, it is ready for weaving, knitting, or pull-up processes, depending on the desired final product shape.

-

Drying: The textile products are then dried to remove excess water, ensuring they maintain their shape and color.

-

Quality Control: Throughout the entire production process, strict quality control measures are implemented to ensure that each product meets international standards and customer expectations.

-

Packaging: Finally, the finished textile products are packaged in accordance with industry standards and sent to their designated destinations worldwide.

Examples: One example of Tianjin Textile Fibers Processing Plant's success can be seen in the development of a new yarn called "Super Tencel." This yarn, made from sustainably sourced Tencel pulp, was developed through a combination of advanced processing techniques and innovative design concepts. The result was a lightweight, breathable, and soft yarn that met the demands of modern clothing trends.

Industry Impact: Tianjin Textile Fibers Processing Plant's commitment to innovation and excellence has had a profound impact on its industry. By adopting state-of-the-art technologies and processes, the plant has become a leader in the production of high-quality textile fibers. This has not only boosted the domestic textile industry but also contributed to China's economic growth and trade expansion.

Global Impact: Beyond China, Tianjin Textile Fibers Processing Plant's achievements have extended far beyond the borders of China. The plant's products have been exported to countries around the world, including Europe, North America, and Asia. This has helped to diversify the Chinese textile industry's export market and fostered cross-cultural exchanges between China and other countries.

Case Study: Let's look at the story of one particular textile product produced by Tianjin Textile Fibers Processing Plant. Imagine a pair of premium silk scarves, designed with a unique blend of traditional craftsmanship and modern technology. These scarves were created using a proprietary blend of silk and polyester fibers, which not only enhanced the wearer's comfort but also showcased the beauty of both natural and artificial materials.

These scarves were not only popular among consumers in China but also gained significant traction globally. Tianjin Textile Fibers Processing Plant's dedication to quality and innovation led to this successful case study, demonstrating that when you put your heart into creating high-quality products, opportunities for global growth are endless.

Conclusion: Tianjin Textile Fibers Processing Plant's journey has been nothing short of remarkable. From the meticulous selection of raw materials to the sophisticated production process, every step was carefully crafted to deliver unparalleled quality in textile fibers. Their achievements not only benefit the Chinese textile industry but also contribute to the global economy, promoting sustainable practices and innovation across borders. As China continues to push boundaries in the textile industry, Tianjin Textile Fibers Processing Plant stands tall, serving as a testament to the power of innovation and excellence in crafting high-quality textiles for a diverse range of global markets.

背景介绍

天津纺织品造粒厂作为天津市纺织业的重要企业之一,以其精湛的工艺、先进的设备和技术,在国内外享有盛誉,该厂不仅生产高质量的纺织品,还注重环保、节能和可持续发展,致力于为社会和人类创造更多的价值。

企业概况

- 企业名称:天津纺织品造粒厂

- 地理位置:天津市南部,靠近港口和交通枢纽

- 历史与发展:该厂创立已有多年历史,凭借着不断创新和不断改进的工艺技术,已经成为国内外知名的纺织企业。

主要产品与服务

- 主要产品:各种类型的纺织品造粒产品,包括但不限于棉、涤纶、丝绸等各类纤维的纺织品。

- 服务范围:该厂提供从原料采购、生产加工到销售服务的全方位服务,满足不同客户的需求。

生产工艺与设备

- 生产工艺:该厂采用先进的生产工艺和技术,注重产品质量和环保、节能等方面,在生产过程中,严格控制原料质量、生产流程和产品质量检测等环节,确保产品的高质量和稳定性。

- 设备情况:该厂拥有先进的生产设备和技术,包括高速纺丝机、造粒机、干燥设备等,这些设备不仅保证了生产效率和质量,还大大提高了生产效率和环保、节能水平。

案例分析

以天津纺织品造粒厂为例,我们可以从以下几个方面进行案例分析:

成功案例一:高效生产与环保节能

近年来,天津纺织品造粒厂在生产过程中注重环保、节能和可持续发展,该厂采用了先进的生产工艺和技术,严格控制原料质量、生产流程和产品质量检测等环节,确保产品的高质量和稳定性,该厂还注重设备的维护和更新,提高生产效率和环保、节能水平,该厂还积极推广绿色生产理念,采用可再生资源进行生产,减少对环境的污染和破坏。

案例分析:具体案例说明

某客户在天津纺织品造粒厂采购了一批高质量的棉纺织品造粒产品,该厂采用了先进的生产工艺和技术,严格控制原料质量、生产流程和产品质量检测等环节,确保产品的质量和稳定性,该厂还注重环保和节能方面的工作,采用了先进的环保设备和节能技术,大大降低了生产成本和能耗,该厂还积极推广绿色生产理念,为客户提供更加绿色、环保的产品和服务。

随着科技的不断发展和社会对环保、节能和可持续发展的需求不断提高,天津纺织品造粒厂将继续加强技术创新和设备更新,提高生产效率和产品质量,该厂还将积极拓展国内外市场,提高品牌知名度和竞争力,该厂还将注重人才培养和团队建设,提高员工素质和工作效率。

天津纺织品造粒厂作为天津市纺织业的重要企业之一,以其精湛的工艺、先进的设备和技术,在国内外享有盛誉,该厂将继续加强技术创新和设备更新,提高生产效率和产品质量,为社会发展做出更大的贡献。

Articles related to the knowledge points of this article:

The Carbon Content of Textiles

Expand Your Career Horizons with the Advancement at Yuxian Textiles!